Multilayer thermal control assembly and preparation method thereof

A component and thermal control technology, applied in the direction of chemical instruments and methods, lamination, coating, etc., can solve the problems of reducing thermal insulation performance, leakage of phase change materials, and impossibility of realization, so as to reduce thermal conductivity and ensure thermal insulation Effect, the effect of improving the heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the multi-layer thermal control assembly of the present invention specifically comprises the following steps:

[0045] (1) Mix the phase change material and the binder, the mass ratio of the phase change material and the binder is: 0.5-1:1, then add a solvent to the mixture of the phase change material and the binder and stir evenly, The viscosity of the mixed solution is 20-35s, the mixed solution is sprayed on the surface of the spacer layer, and solidified to form a spacer layer containing the phase change material.

[0046] The phase change material has a microcapsule structure, and the microcapsule structure is an alkane microcapsule or a paraffin microcapsule, and the particle size is 50-200 μm. The microcapsule structure is a single type of alkane microcapsule or a mixture of different types of alkane microcapsules; or the microcapsule structure is a single type of paraffin microcapsule or a mixture of different types of paraffin microca...

Embodiment 1

[0053] 1. Phase change material coating: Mix silicone rubber and docosane microcapsules at a weight ratio of 1:0.7, mix the silicone rubber and docosane microcapsules evenly by adding gasoline and adjust the viscosity to 25-30s, Coated on the surface of the nylon mesh by spraying, the spray gun diameter is 2.0mm, the spraying distance is 18-26cm, the spraying thickness is 150±20μm, and it is used after 24 hours of curing;

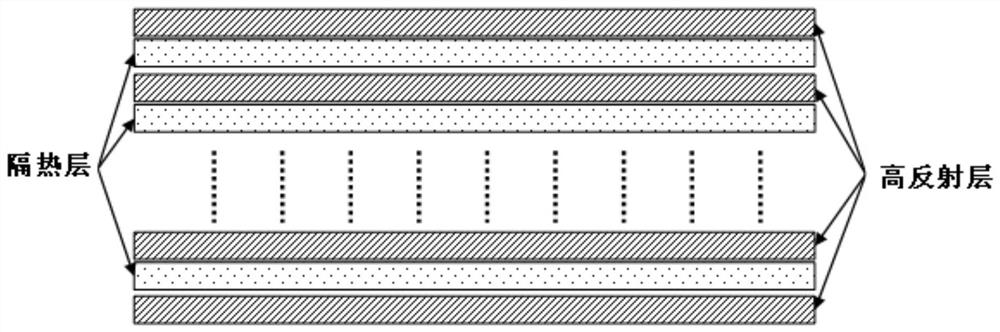

[0054] 2. Layer: according to figure 1 In the structure shown, the aluminized polyimide film and the heat insulation layer are alternately laminated, and the number of laminated layers is 11; the heat insulation layer is nylon mesh and the above-mentioned nylon mesh sprayed with phase change material, which is automatically The sixth layer from top to bottom is nylon mesh sprayed with phase change material, and the remaining layers are nylon mesh.

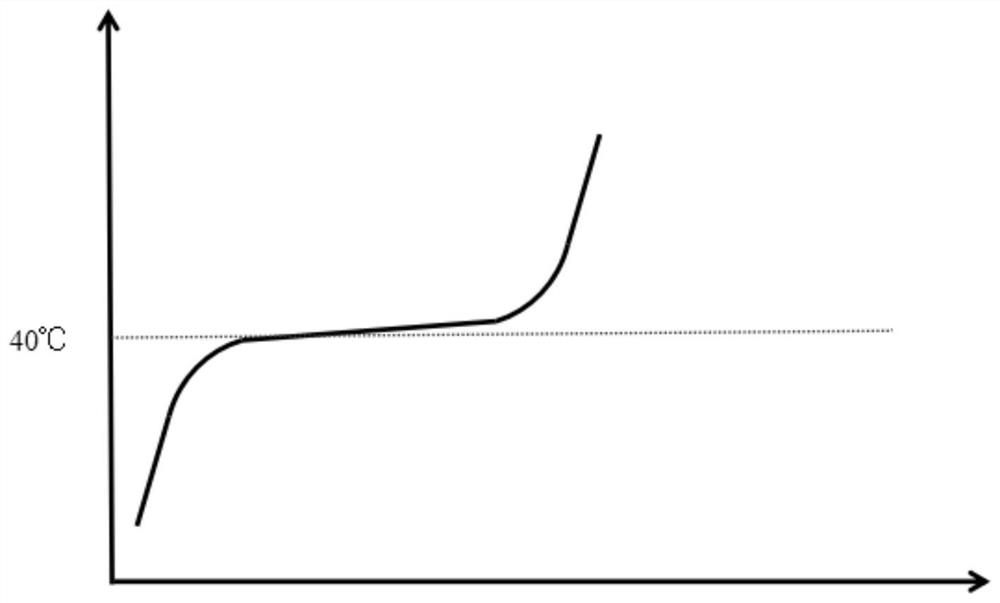

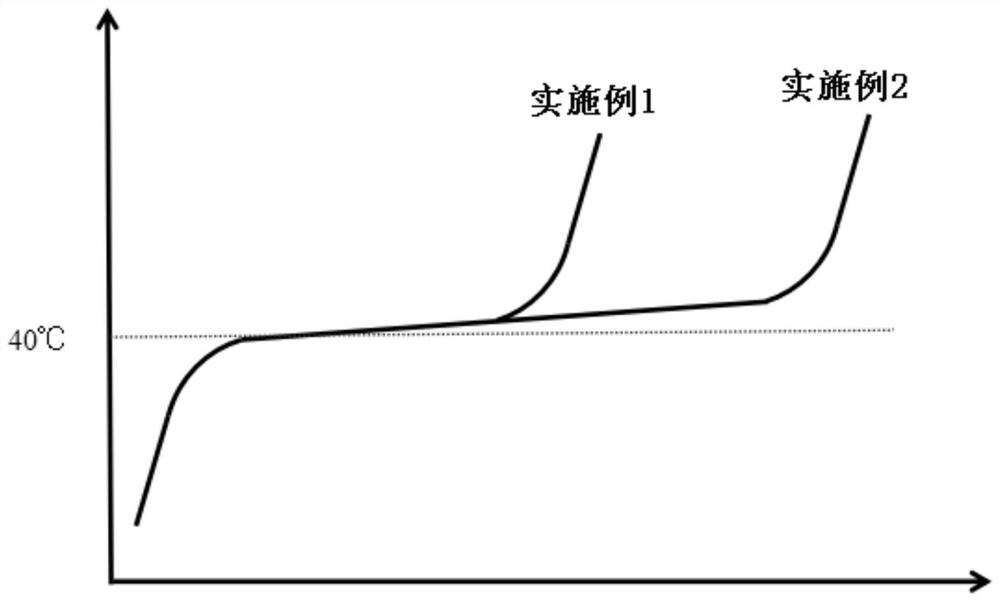

[0055] Implementation effect: The equivalent thermal conductivity of the prepared multilayer thermal control...

Embodiment 2

[0058] 1. Phase change material coating: Mix silicone rubber and docosane microcapsules at a weight ratio of 1:0.7, mix the silicone rubber and docosane microcapsules evenly by adding gasoline and adjust the viscosity to 25-30s, Coated on the surface of the nylon mesh by spraying, the spray gun diameter is 2.0mm, the spraying distance is 18-26cm, the spraying thickness is 150±2μm, and it is used after 24 hours of curing;

[0059] 2. Layer: according to figure 1 In the structure shown, the aluminized polyimide film and the heat insulation layer are alternately laminated, and the number of laminated layers is 11; the heat insulation layer is nylon mesh and the above-mentioned nylon mesh sprayed with phase change material, which is automatically The 4th and 6th layers from top to bottom are nylon meshes sprayed with phase change materials, and the remaining layers are nylon meshes.

[0060] Implementation effect: The equivalent thermal conductivity of the prepared multilayer the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com