High-voltage equipment box

A technology for high-voltage equipment boxes and high-voltage areas, which is applied to the setting of switchgear, supporting insulators, grounding devices, etc., can solve the problems of unfavorable vehicle roof installation structure load-bearing, inconvenient maintenance, and the overall volume and weight of the box. Improve the safety of maintenance, reduce the weight of the box, and ensure the effect of insulation isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

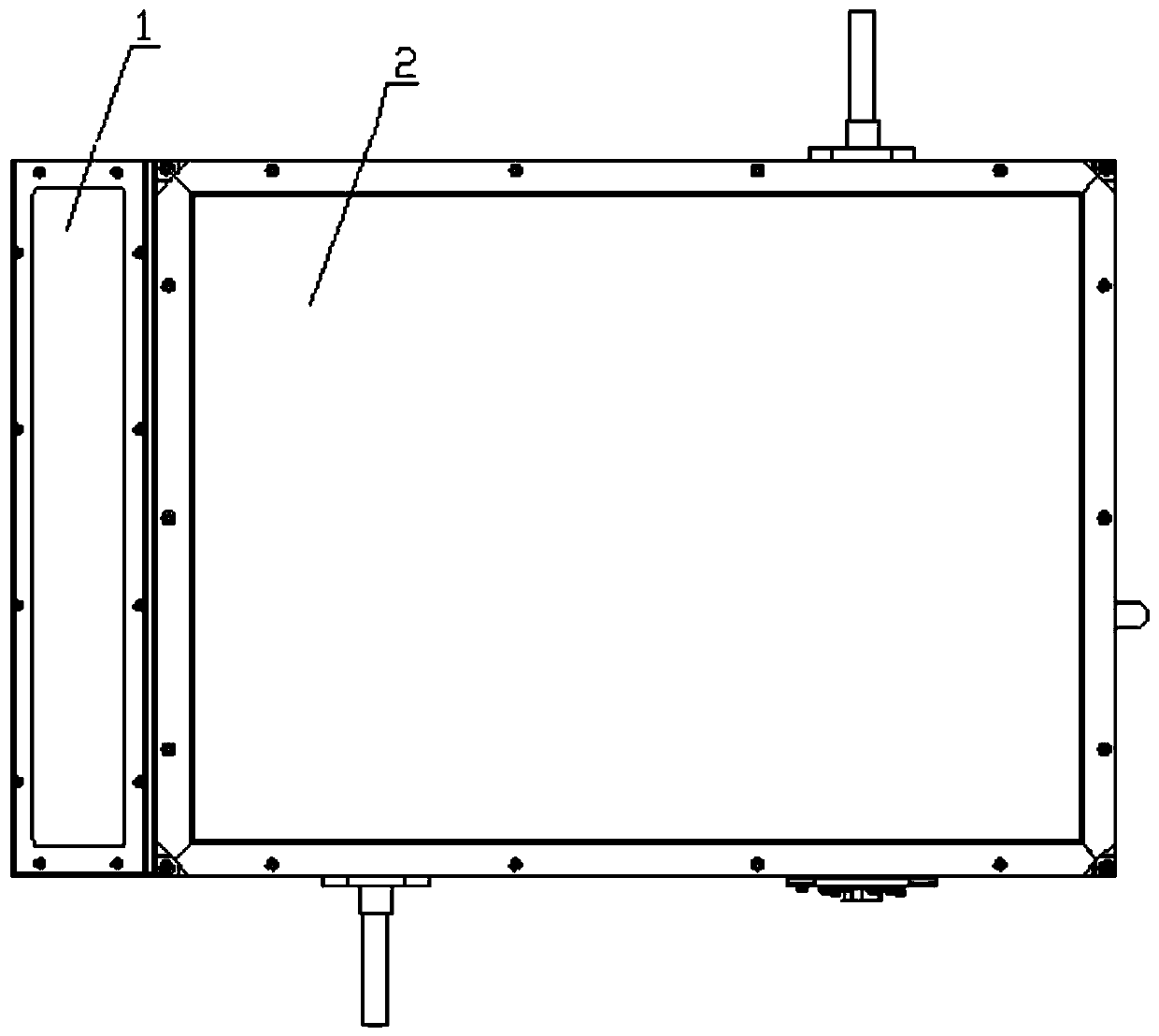

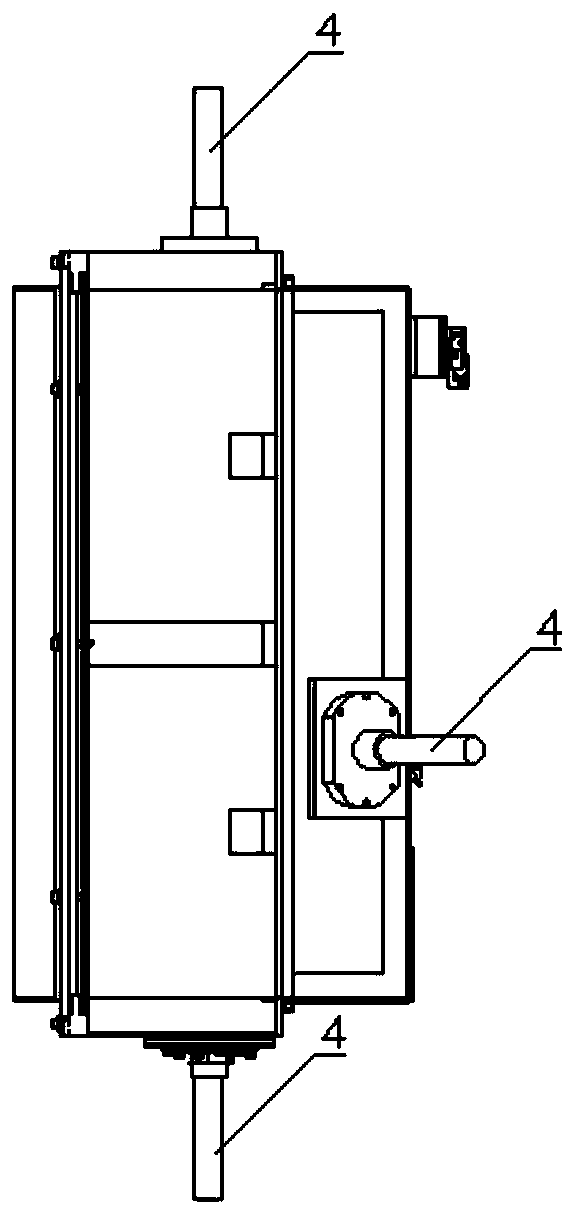

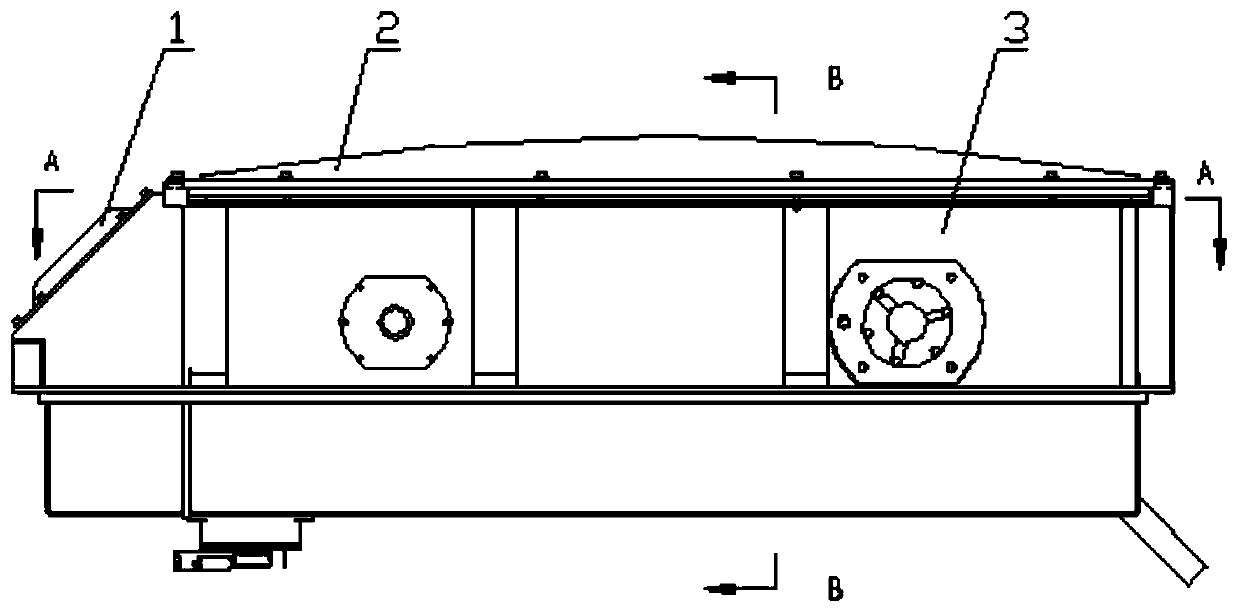

[0036] Such as Figure 1-16 As shown, a high-voltage equipment box includes a box body 3. The box body 3 is the mechanical installation body for carrying the equipment in the box body. 4. The inside of the box body 3 is divided into two parts, the high-pressure area and the low-pressure area, by an aluminum alloy partition plate 3.1. The main top cover 2, the inspection cover 1 and the main top cover 2 are installed on the box body through fasteners. During maintenance, only the inspection cover 1 needs to be disassembled, and the main top cover 2 is in a sealed and closed state for a long time.

[0037] The specific structure in the box body 3 includes: high-voltage grounding switch 5, voltage transformer 6, bottom insulation partition 7, middle insulation partition 8, voltage equalizing ring 9, lightning arrester 10, high-voltage isolation switch 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com