Efficient cast copper self-starting permanent magnet motor

A permanent magnet motor and self-starting technology, which is applied to synchronous motors with stationary armatures and rotating magnets, synchronous machines, electrical components, etc., can solve the problems of burning motor windings, large starting current, and demagnetization of magnetic steel. Achieve the effect of reducing starting current, reducing impact and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

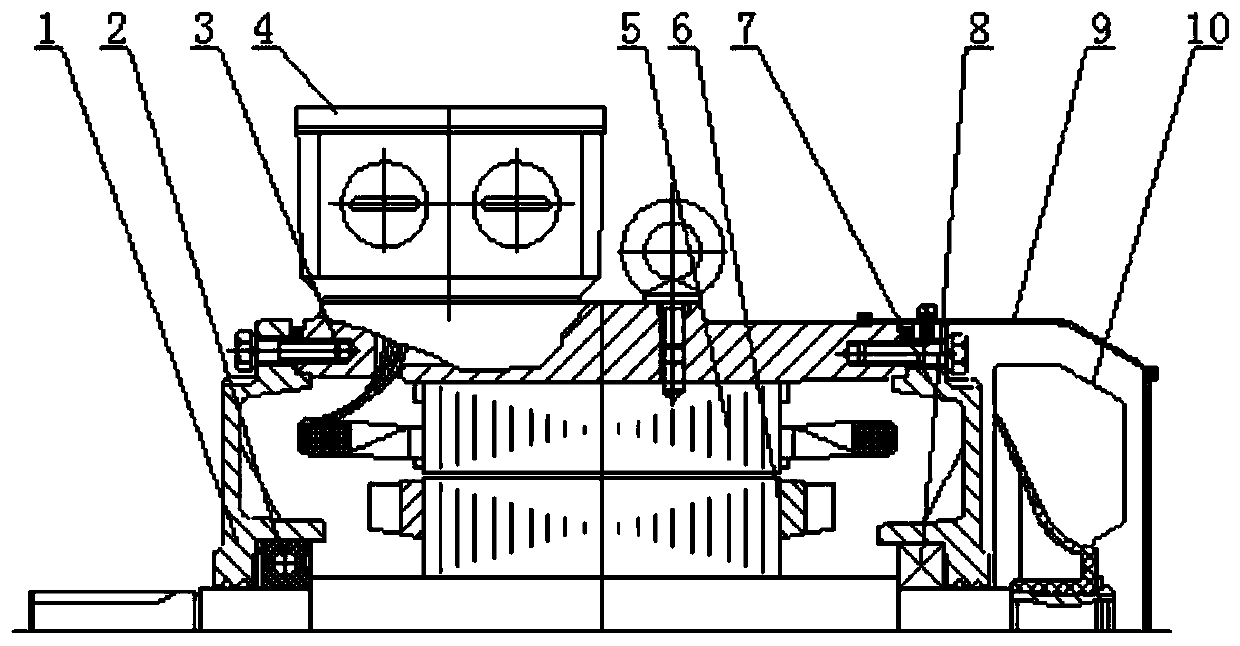

[0020] Such as Figure 1-3 As shown, it is a high-efficiency cast copper self-starting permanent magnet motor provided by the present invention, which includes a housing made of a base 3 and front end covers 1 and rear end covers 7 on both sides, and the front end cover 1 is provided with a front bearing 2. The rear end cover 7 is provided with a rear bearing 8, the stator core 5 and the motor rotor 6 are set in the housing, and the circuit of the stator core 5 is connected to the junction box 4 outside the housing. An outer fan 10 is arranged on the outside of the rear end cover 7 , and a windshield 9 is arranged outside the outer fan 10 .

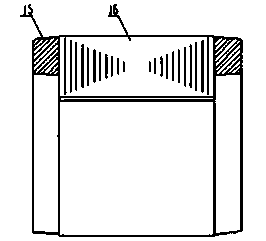

[0021] Such as figure 2 As shown, the motor rotor 6 includes an end ring 15 and a cast copper rotor core 16 .

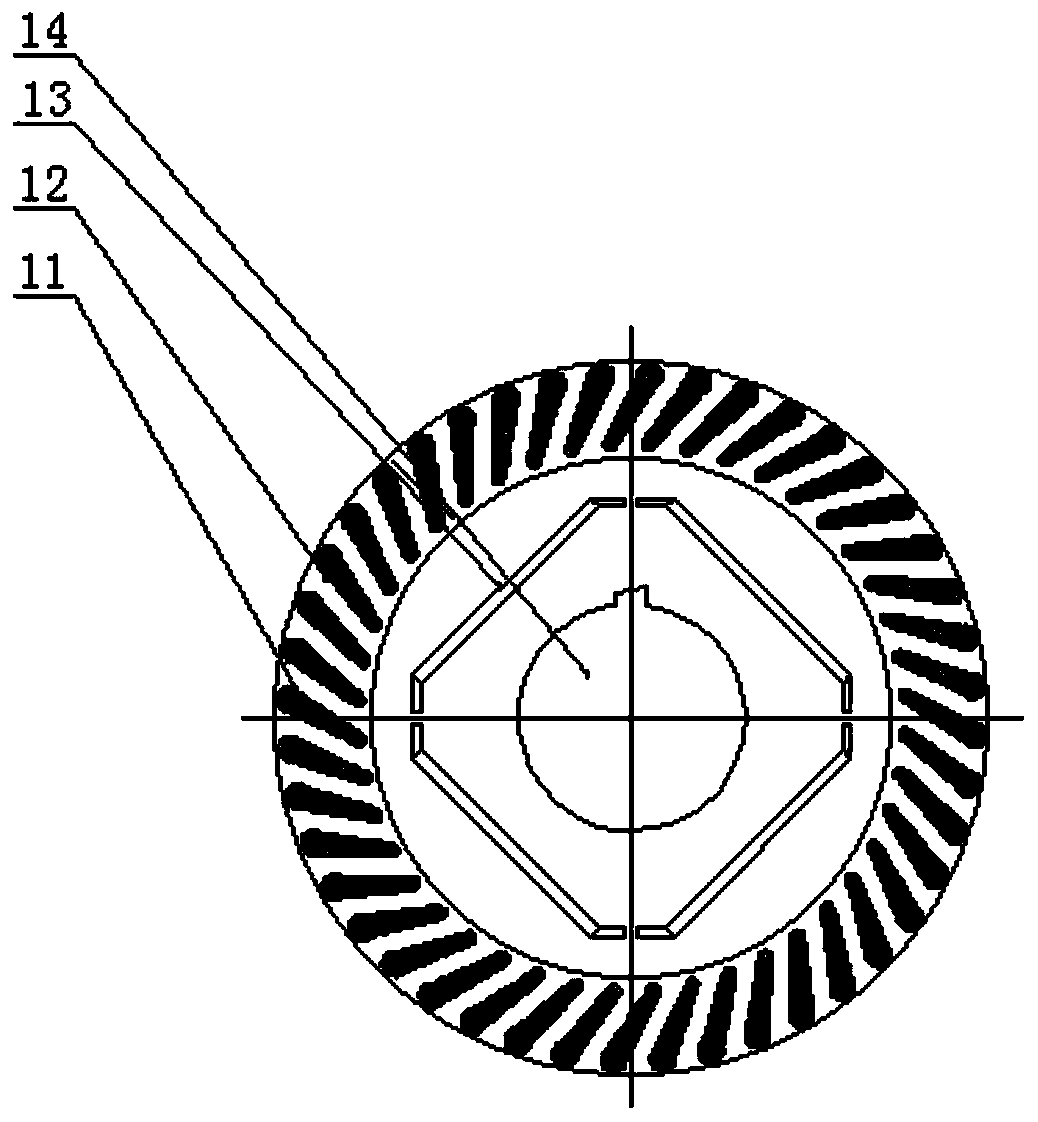

[0022] Such as image 3 As shown, the motor rotor 6 includes mutually nested rotor punches 11 and shafts 14, the side of the rotor punches 11 close to the shaft 14 is embedded with permanent magnets 13; the rotor punches 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com