Fluorine coating agent having enhanced dental tubule permeability and coating endurance and method for preparing same

A dentin tubule and coating agent technology, which is applied in dental preparations, tooth protection coatings, dentistry, etc., can solve the problems of impermeability of preparations, reduction of dentin tubule blocking force, and unexpectable sensory hypersensitivity inhibition effect, etc., to achieve Effects of preventing caries, reducing tooth sensitivity, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067]On the other hand, another embodiment of the present invention relates to a preparation method of a fluorine coating agent having improved dentin tubule penetration and coating retention, the preparation method may include: a first dissolving step, by A high molecular weight polyvinyl acetate (Poly(vinyl acetate), PVAc) with an average molecular weight of 300,000 to 600,000 is dissolved in a solvent to prepare a first solution; in a second dissolving step, rosin is dissolved in a solvent to prepare a second solution; and In the mixing step, the second solution, the fluorine compound and the emulsifier are added to the first solution and stirred.

[0068] Since the specific descriptions of the solvent, rosin, fluorine compound, and emulsifier used in the above-mentioned preparation method of the fluorine coating agent have been mentioned above, they will be omitted here.

[0069] The above-mentioned first dissolving step is a step of preparing a first solution by dissolvi...

preparation example

[0079] Preparation of fluorine coating agent

[0080] First, polyvinyl acetate having the weight average molecular weight shown in Table 1 below was evaporated in 94% ethanol at 65° C. to prepare a 30% PVAc solution, ie, a first solution.

[0081] Then, rosin was steamed at 65° C. in 94% ethanol to prepare a 70% rosin solution, ie, a second solution.

[0082] In the first solution above, mix the second solution, fluorine compound, CPP-ACP, silicon dioxide, potassium nitrate and emulsifier in the same ratio as in Table 1 below to prepare as figure 1 Example 1 and Comparative Example 2 of the fluorine coating agent shown.

[0083] Table 1

[0084]

[0085]

[0086] (unit: weight percentage)

experiment example 1

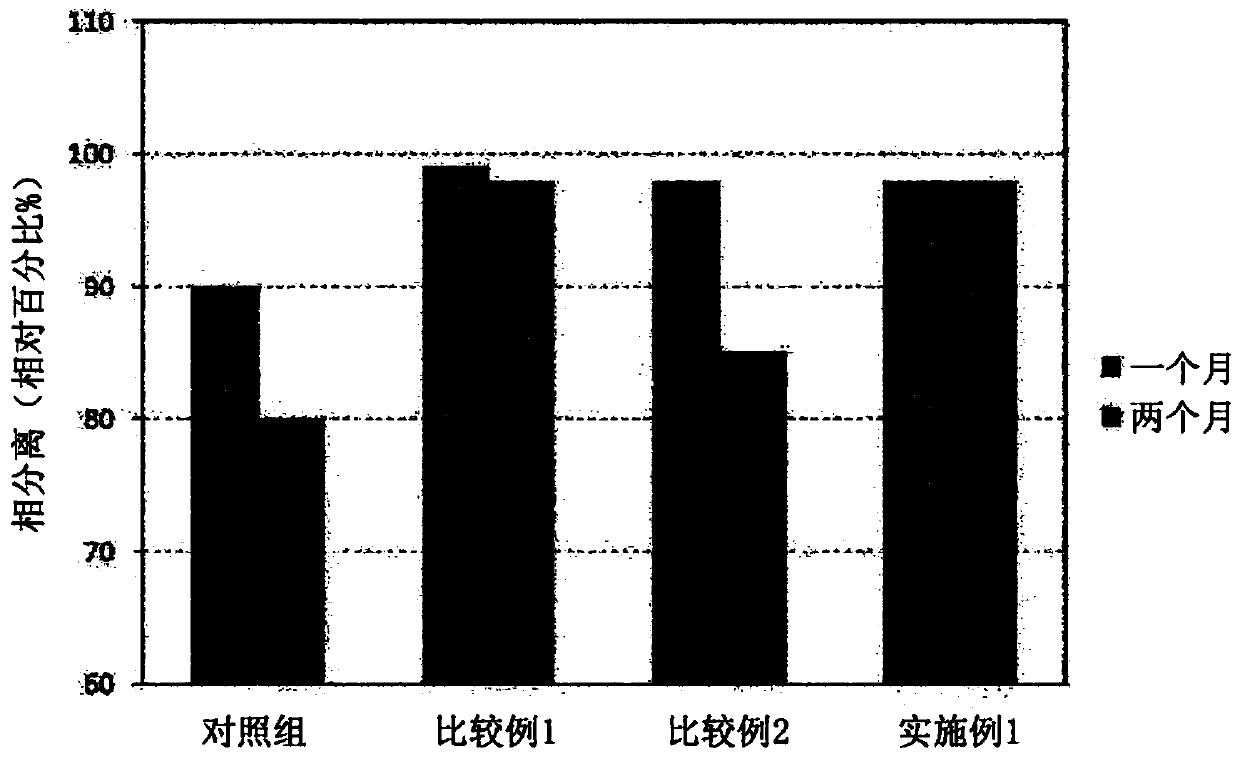

[0088] Phase Separation Phenomena According to Emulsifier Conditions

[0089] 1) Observe the phase separation phenomenon according to whether emulsifier is included

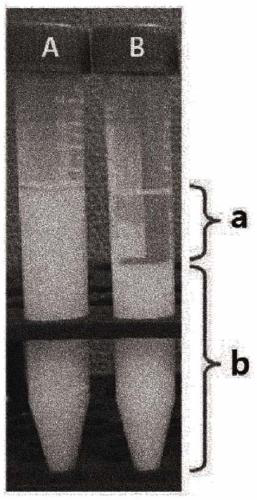

[0090] First, in order to confirm the phase separation phenomenon depending on whether or not to add an emulsifier, a control group (B) was prepared in the same preparation method as Example 1 (A) of the above-mentioned preparation example except that a solvent was further added instead of the emulsifier.

[0091] Put 10 ml of each of the above-mentioned Example 1 and the control group (B) into conical tubes, let stand at room temperature for 45 days, and then observe whether phase separation occurs.

[0092] Such as figure 2 As shown, after 45 days, phase separation is hardly observed in Example 1 (A) containing emulsifier, but in the control group (B) without emulsifier, it can be confirmed that polyvinyl acetate and hydrogenated rosin , the precipitated layer (b) and the supernatant (a) formed by the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com