Extrusion tool for extruding fittings for making pipe connections

一种挤压工具、管连接的技术,应用在不可拆卸的管连接、管子/管接头/管件、制造工具等方向,能够解决无法轻易地确定挤压力等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In the following description of the embodiments according to the present invention, the same components are marked with the same reference numerals, even though these components may have differences in size or shape in different embodiments.

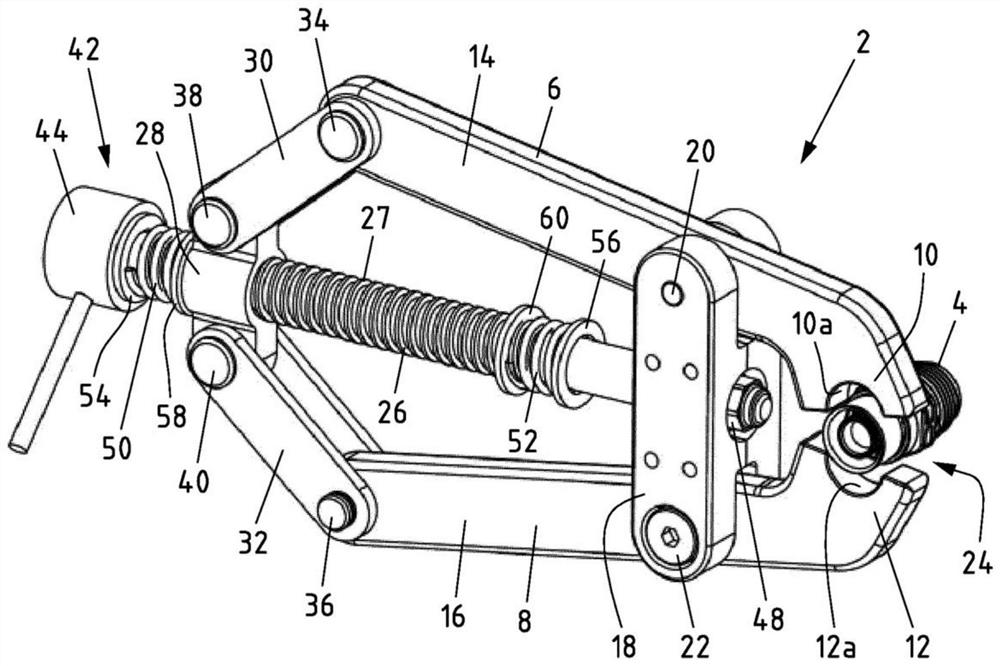

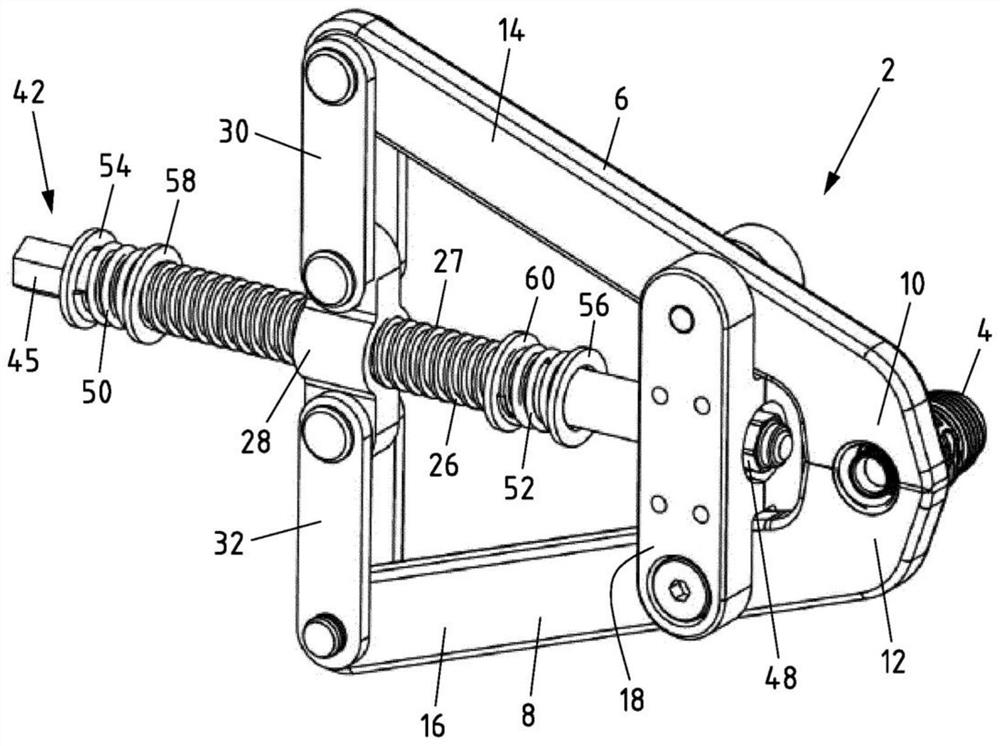

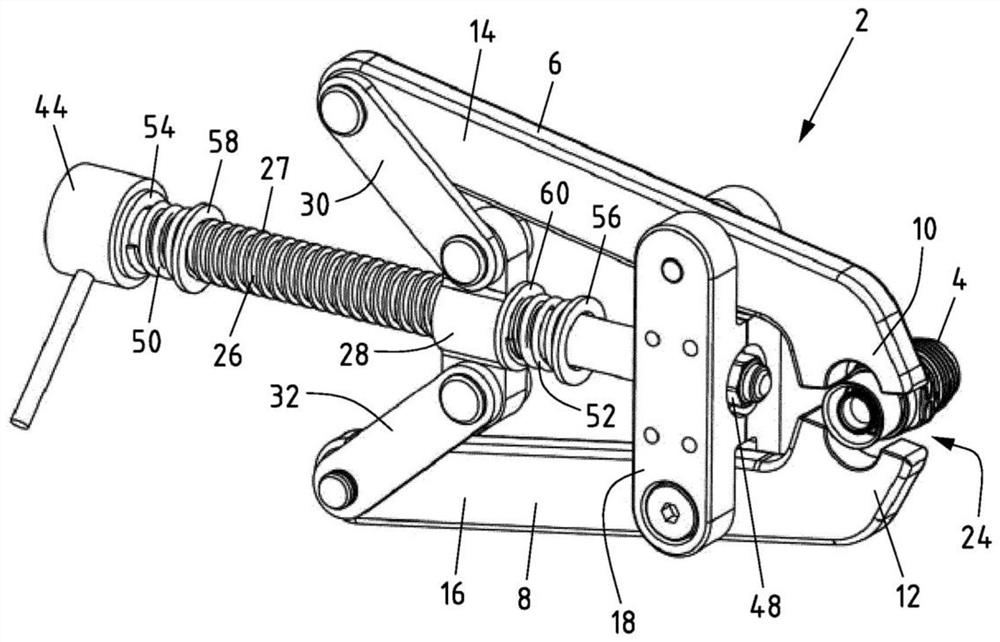

[0068] Figures 1a to 1c A pressing tool 2 for pressing fittings 4 for producing pipe connections is shown, wherein the corresponding pipes are not shown in FIG. 1 .

[0069] The pressing tool 2 has two opposing pressing jaws 6 and 8 , each having a pressing section 10 , 12 and a lever section 14 , 16 . The fastening element 18 connects the pressing jaws 6 and 8 pivotably to one another by means of two bolts 20 and 22 . The extrusion sections 10 , 12 form a receiving area 24 in which the fitting 4 is accommodated. The extruded sections 10 , 12 have for this purpose inner surfaces 10 a , 12 a with an extruded contour adapted to the outer contour of the fitting 4 .

[0070] Due to the shown geometry of the pressing tool 2 , pushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com