Expansion wedge unit

A wedge-shaped, guiding unit technology, applied in the direction of gear transmission mechanism, drum brake, brake type, etc., can solve the problems of shaking contact surface, wear, braking application can not be properly controlled, etc., to achieve the effect of tight guiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

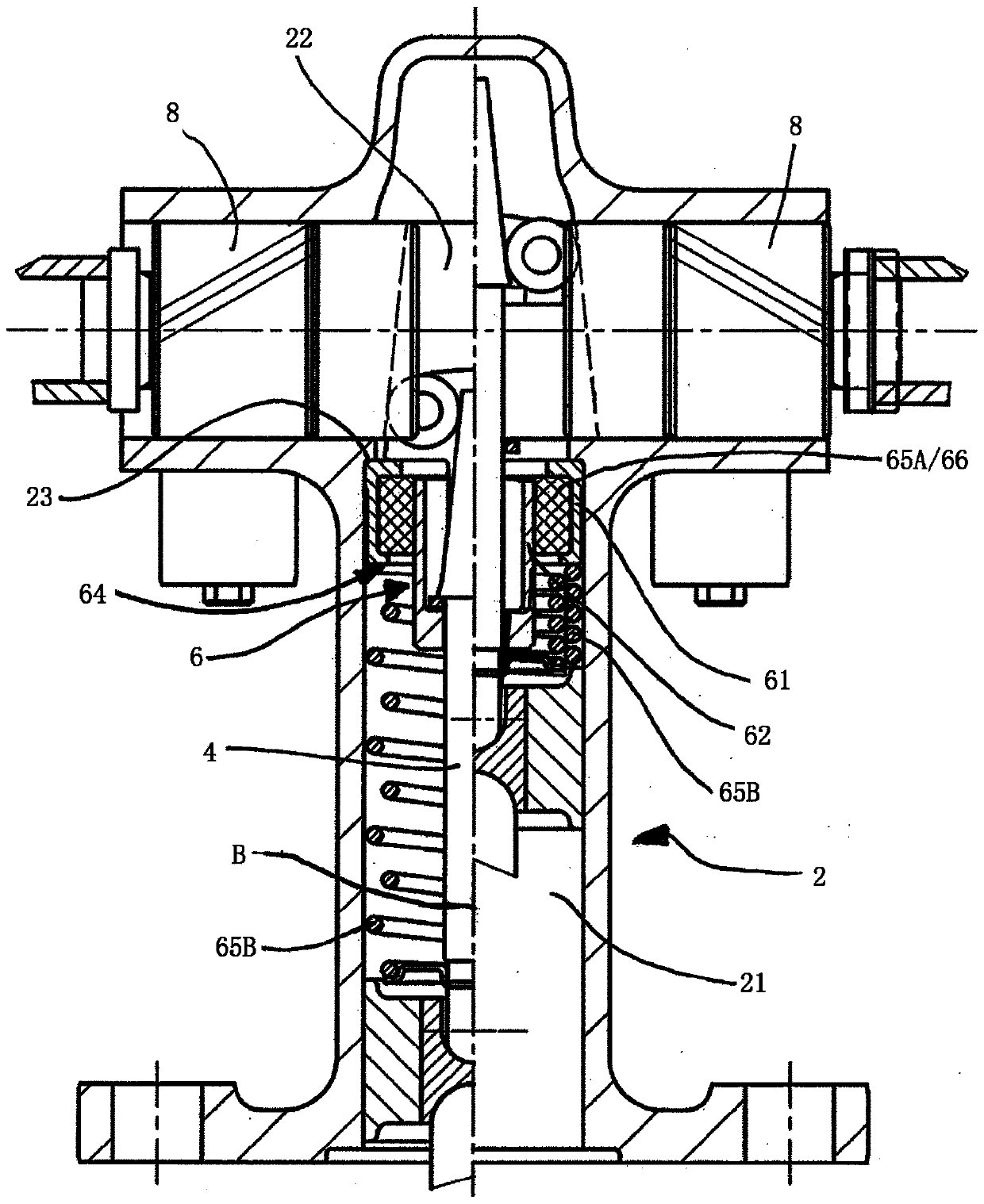

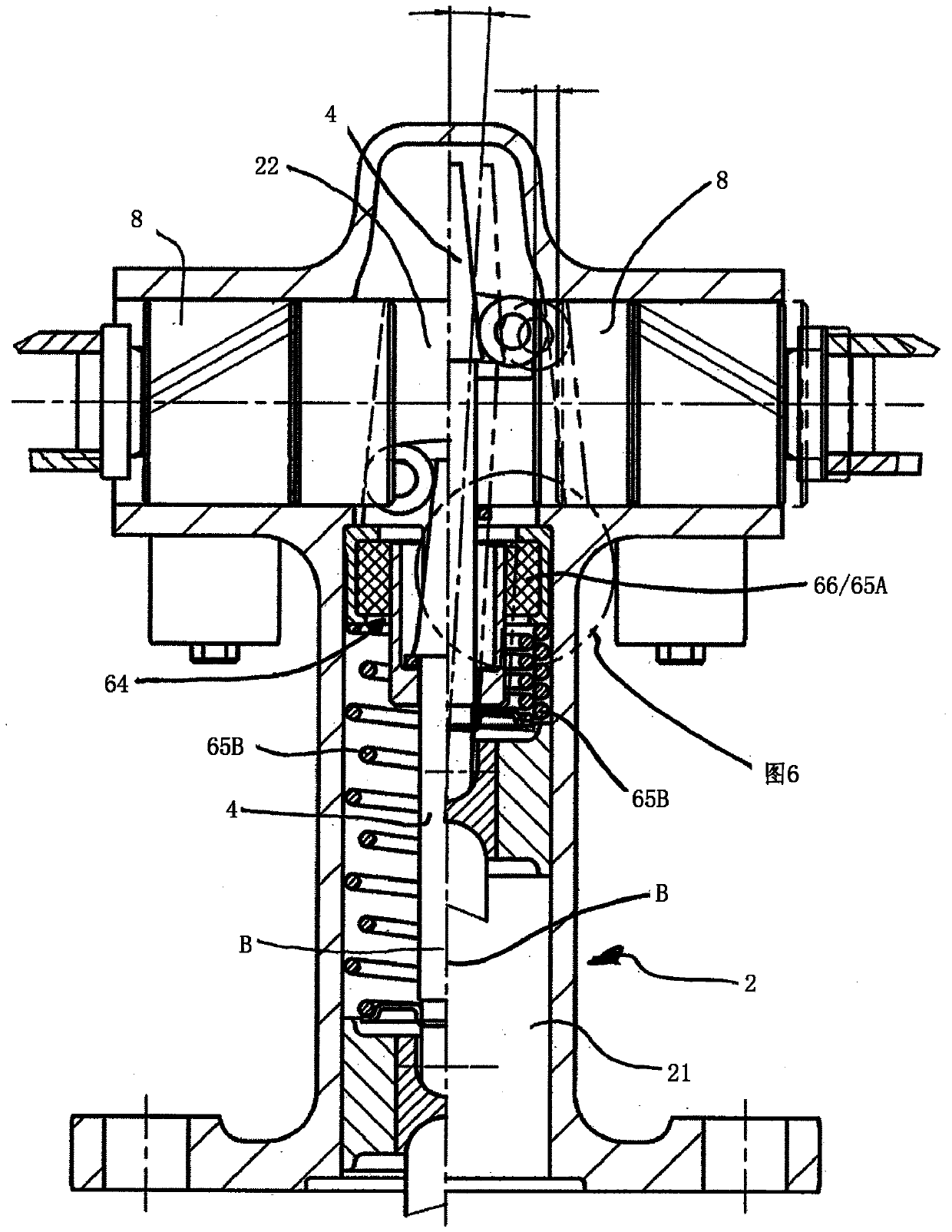

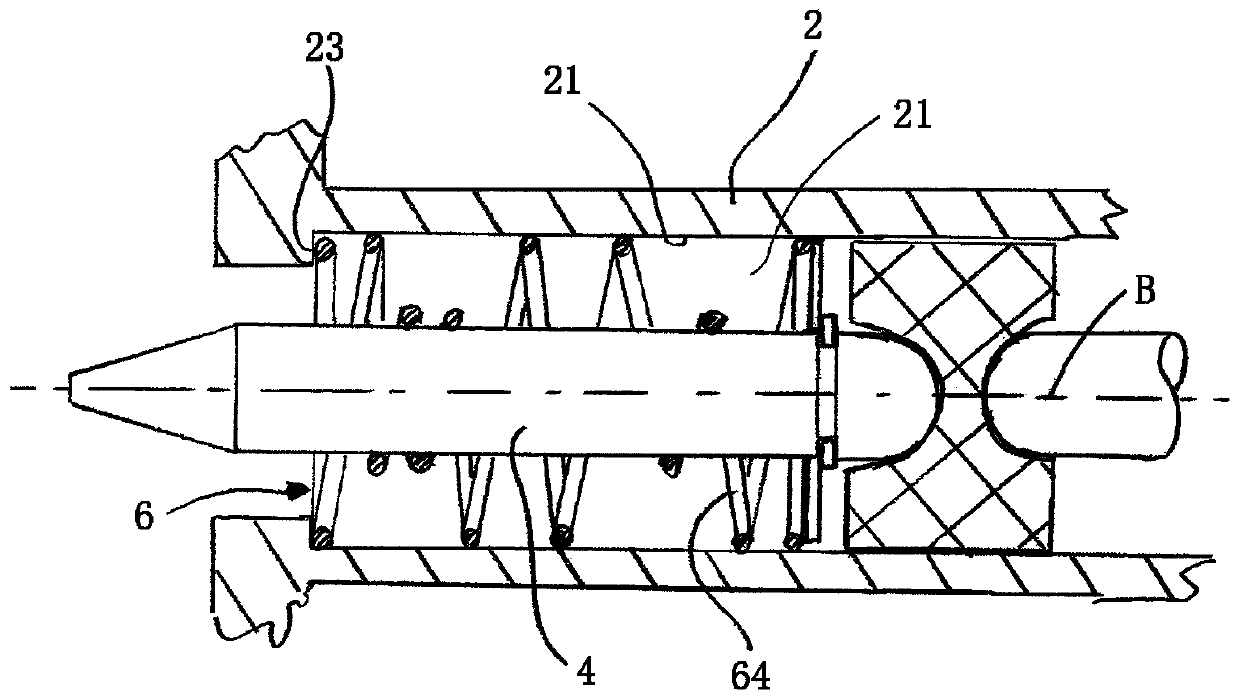

[0026] figure 1 and figure 2 The preferred embodiment of the expansion wedge unit shown in has a housing 2 with a first housing region 21 and a second housing region 22 . Preferably, the first housing region 21 is substantially cylindrical and extends along the actuation axis B with a substantially constant cross section. figure 1 and figure 2 The left half of , shows the state of the expanding wedge unit in which the expanding wedge extends maximally from the second housing region 22 , ie in the non-actuated state of the brake. The corresponding right half of the figure shows the state in which the expansion wedge is maximally retracted into the second housing area 22 and thus achieves a maximum deflection of the piston element 8 and the brake shoe supported thereon . The first spring member 65A is a rubber member 66 disposed between the first guide portion 61 and the second guide portion 62 . The second spring element 65B is a helical spring with windings of different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com