Sowing machine capable of precision sowing and sowing method thereof

A technology of precision seeding and seeding machine, which is applied in the direction of single-seed seeding machine, seeding machine parts, botanical equipment and methods, etc. inequality problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

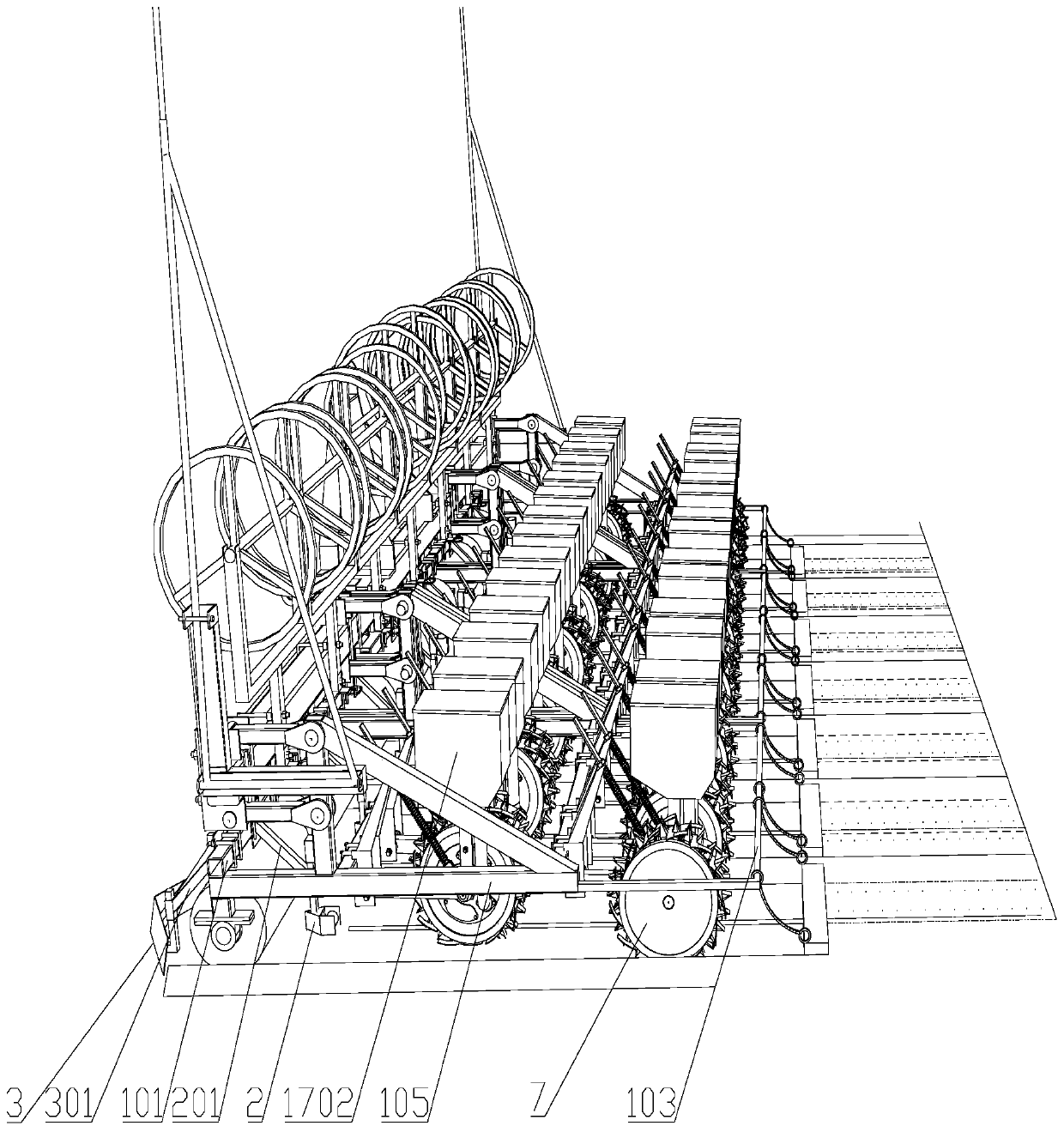

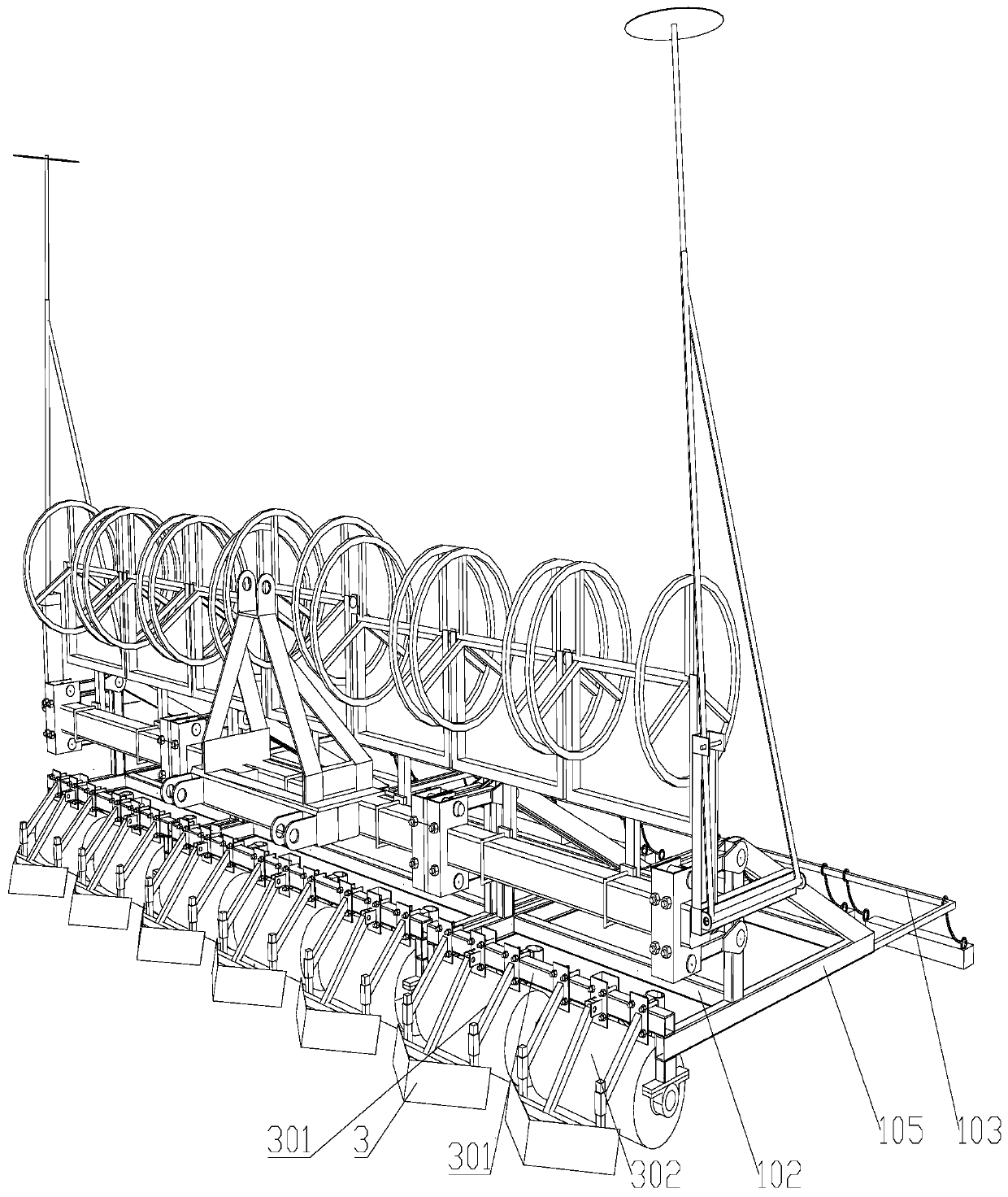

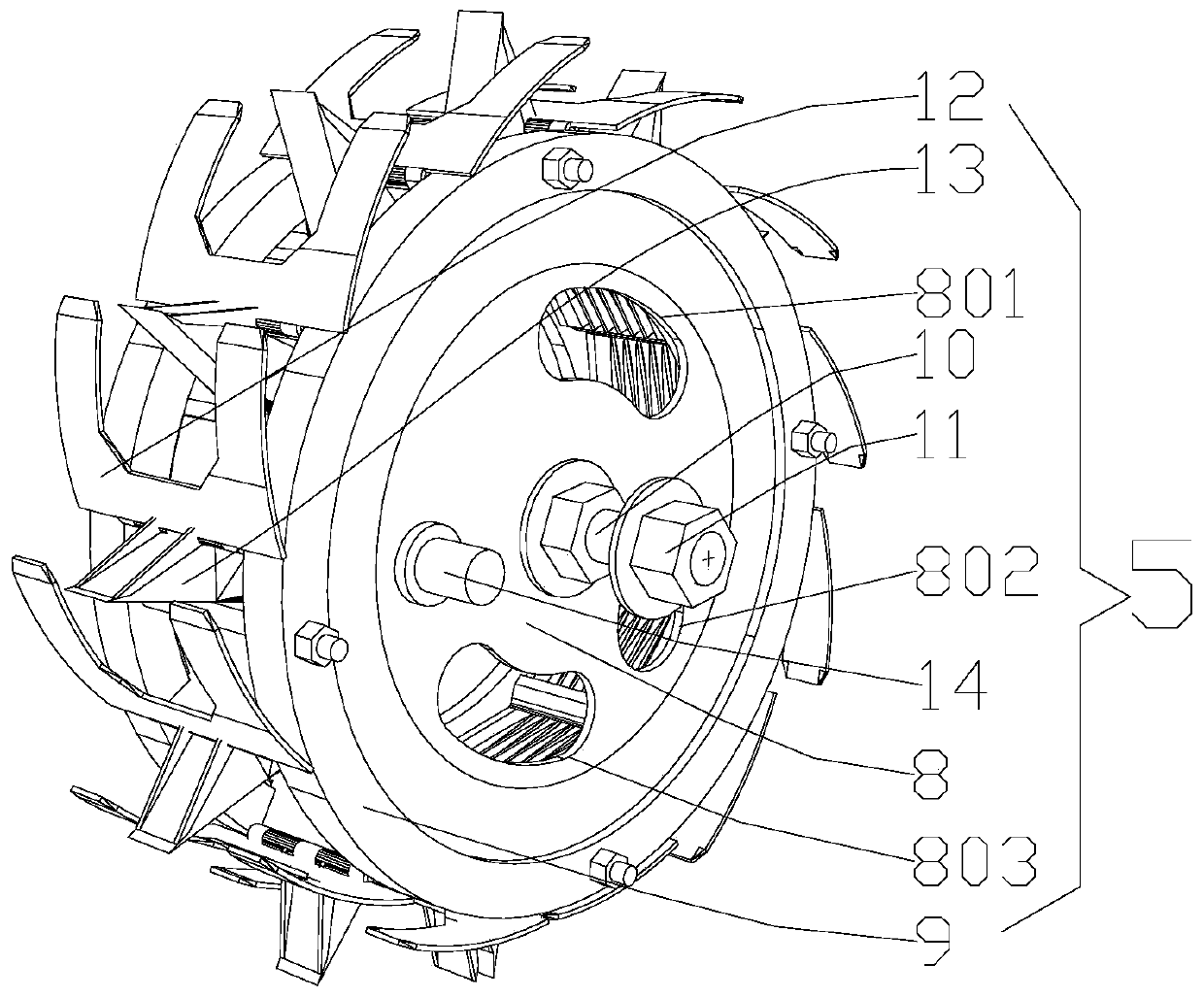

[0075] Such as figure 1As in 11, a seeder for precision sowing, comprising several drillers 5 and multiple rows of corolla frames, on which several rows of drillers 5 that can rotate are installed, and the drillers are equipped with Described hole sowing device 5 comprises several precision seed pickers 6, several sheet-like moving hole nozzles 12 for planting, several fixed hole nozzles 13 for entering the soil, vertically arranged rotating wheels 7, two vertically arranged fixed hole nozzles. Disk 8, vertically arranged rotating disk 9 and horizontally arranged main fixed shaft 10, wherein: precision seed picker 6 includes horizontally arranged rotating block 601, horizontally arranged and strip-shaped fixed base 605, horizontally arranged and Elongated seed nest piece 606 and limiting channel; the top surface of the rotating block 601 is provided with several through grooves 602 arranged along the length direction of the rotating block 601, and one side of the seed nest blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com