Fermented bagasse raw material used for feed, and preparation method thereof

A technology for fermenting bagasse and bagasse, applied to animal feed, animal feed, bacteria used in food preparation, etc., can solve the problems of rough texture of bagasse, limit the application of bagasse, poor palatability, etc., and improve the nutritional structure , Improve digestibility and protein content, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 fermented bagasse feed material

[0032] 1. Bagasse puffing

[0033] Expansion group 1: bagasse with a moisture content of 44%, crushed to 15 mm, and puffed the crushed bagasse with an extruder at a temperature of 130° C., a pressure of 2 MPa, and a duration of 4 s.

[0034] Expansion group 2: bagasse with a moisture content of 48%, crushed to 30 mm, and puffed the crushed bagasse with an extruder at a temperature of 120° C., a pressure of 4 MPa, and a duration of 3 s.

[0035] Expansion group 3: Bagasse with a moisture content of 52%, crushed to 2mm, and puffed the crushed bagasse with an extruder at a temperature of 140°C, a pressure of 0.5Mpa, and a duration of 5s.

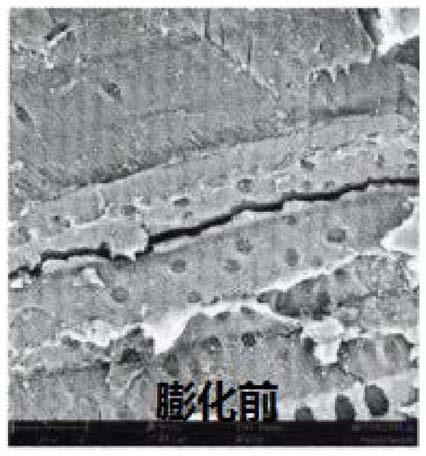

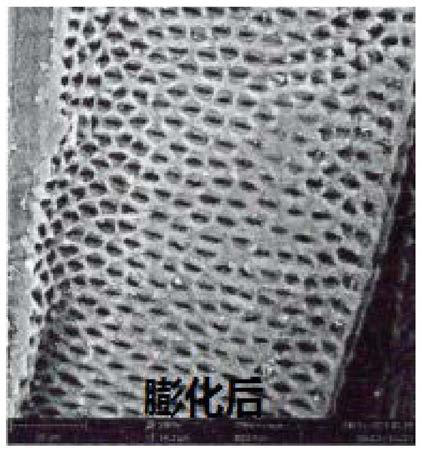

[0036] The high temperature naturally produced by mechanical puffing can achieve the effect of curing and sterilization. The bagasse before puffing and the puffed bagasse obtained by puffing group 1 were scanned by electron microscope, from the scanning electron microgra...

Embodiment 2

[0057] Example 2 Quality Evaluation of Feed Raw Material of Expanded and Fermented Bagasse

[0058] Sensory evaluation: the content of water-soluble carbohydrates in bagasse is low, and the number of lactic acid bacteria attached to itself is small. Adding bacteria can make up for the lack of lactic acid bacteria in bagasse itself, and enzymes can decompose cellulose and provide carbohydrates for the growth of lactic acid bacteria.

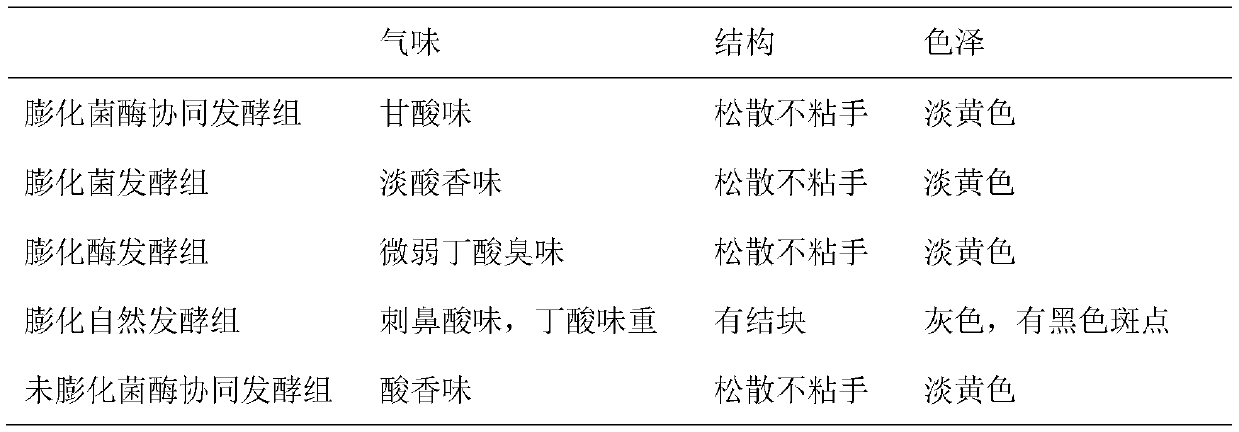

[0059] As shown in Table 1, black spots appeared in the puffed natural fermentation group, and a pungent sour smell was smelled after opening, and the color was brown and agglomerated. The puffing bacteria fermentation group and the puffing enzyme fermentation group smelled a weak sour smell respectively, and the puffing enzyme fermentation group also had a weak butyric acid odor; in terms of color, the puffing bacteria fermentation group was light yellow, which was closer to the color of bagasse itself. The enzyme fermentation group was slightly...

Embodiment 3

[0075] Example 3 Feed test of puffed and fermented bagasse feed material

[0076] A total of 90 Simmental crossbred cows aged 14 to 16 months who were healthy and with basically the same physical development were selected and randomly divided into 3 groups with 30 heads in each group. The experimental group I was the control group, fed with concentrate and yellow stalks, and the second group In group Ⅲ, bagasse fermented with enzymes of unexpanded bacteria and bagasse fermented with enzymes of puffed bacteria were used to replace the same amount of dry matter of yellow storage corn stalks. Feed the same amount of concentrate and roughage every day, the ratio of concentrate to roughage is 45:55, the feeding amount of concentrate is 3.5kg per head, the feeding amount of yellow storage corn stalks and fermented bagasse is 10kg and 8kg respectively. For the formula of concentrate, refer to the Chinese agricultural industry standard NY / T 815-2004 "Beef Cattle Feeding Standard". See...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com