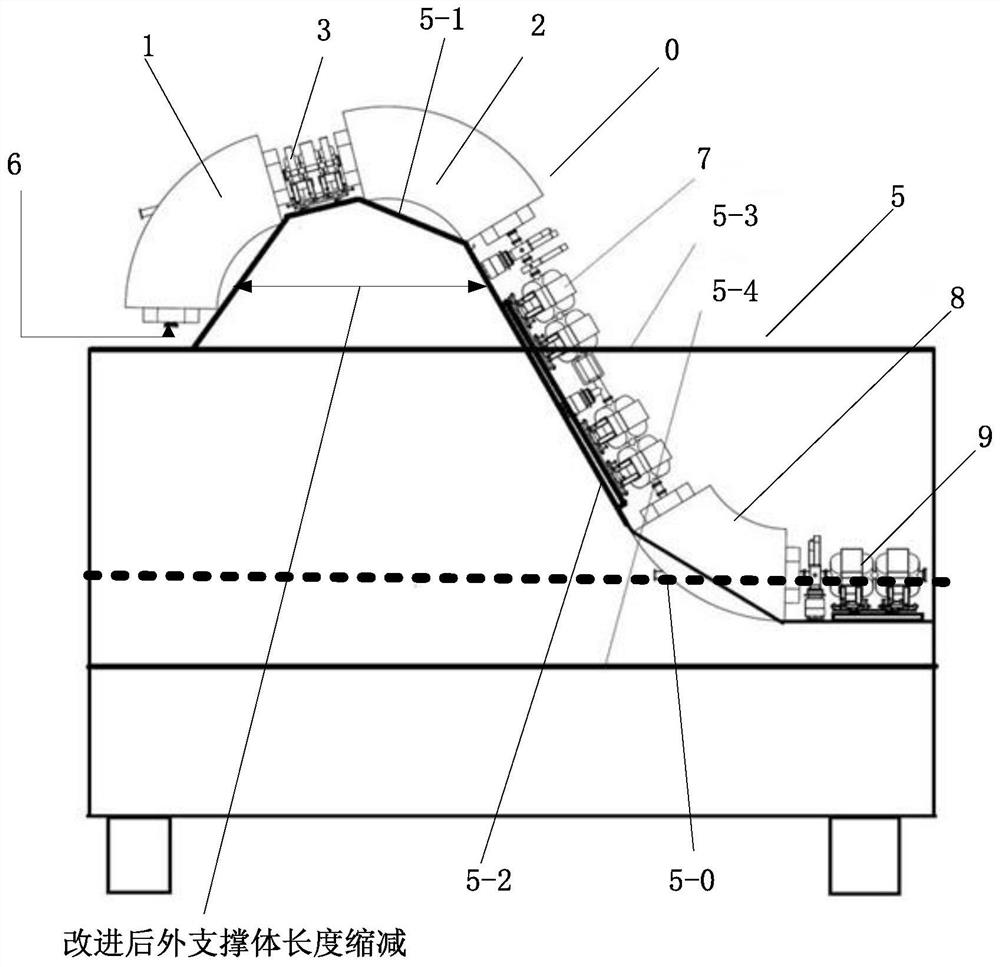

A beam line deflection magnet assembly, installation method, and rotating frame of the assembly

A deflecting magnet and rotating gantry technology, applied in the directions of X-ray/γ-ray/particle irradiation therapy, radiotherapy, irradiation device, etc., can solve the problem that the total length of the deflecting magnet assembly cannot be reduced, the weight of the rotating gantry is too heavy, and it is inconvenient Medical diagnosis and other issues, to achieve the effect of highlighting the substantive characteristics, reducing the total weight, and shortening the length and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

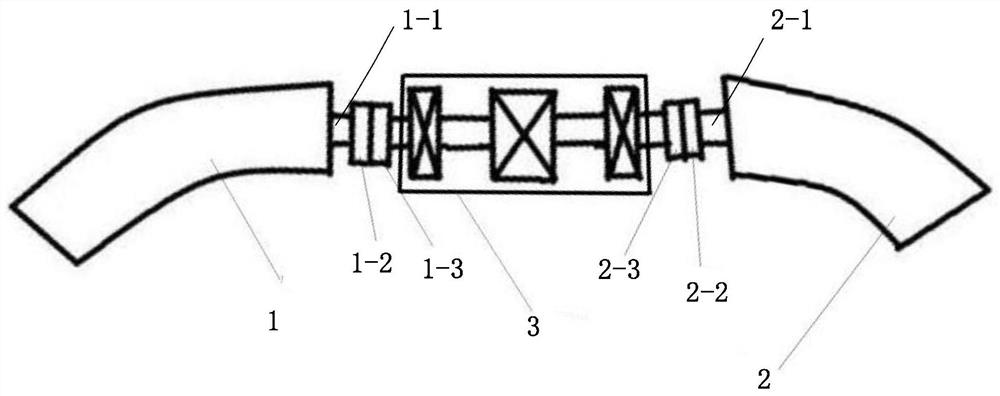

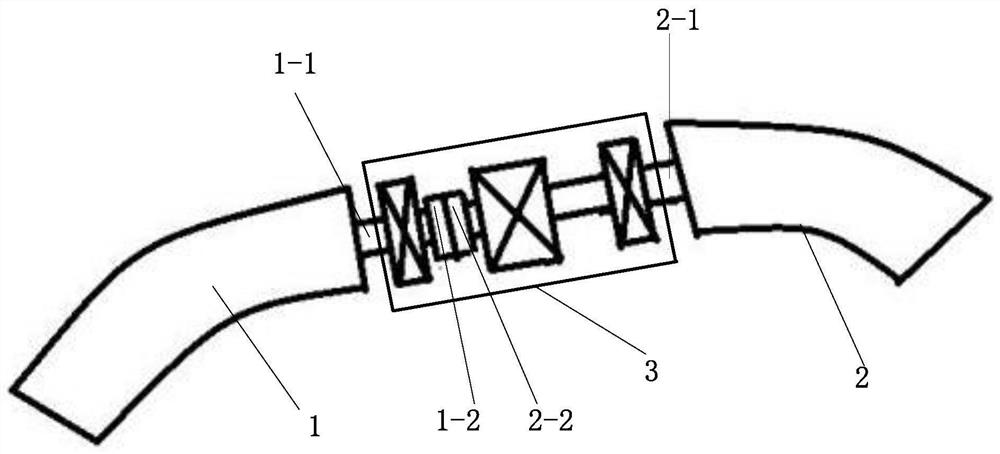

[0048] Describe in detail below in conjunction with accompanying drawing

[0049] Design principle of the present invention

[0050] 1. Advantages and disadvantages of internal mounting flanges. In this embodiment, the flange assembly is arranged inside multiple four-stage lens assemblies. The advantage is that the flange assembly only occupies the minimum gap space between the original coil and the coil. This minimum gap is to ensure that the coil does not collide with the coil. The minimum gap, the minimum gap is only 24 mm, the gap of 24 mm can only accommodate the width of the two flange end caps, if the two flange end caps are connected together, there must be enough space at both ends of the flange end caps for installation The fastening device that connects two flange end caps, for example, in the prior art, an installation space of 100 mm is left for each set of flanges to connect the two flanges. Obviously, when the flange components are arranged on multiple quadrupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com