Telescopic wing mechanism with slotted flap and continuously variable wingspans

A telescopic machine and flap technology, applied in the directions of wings, wing adjustment, aircraft parts, etc., can solve the problem that the wings cannot adapt to the requirements, reduce the induced resistance and airfoil resistance, reduce the take-off angle of attack, and reduce the parasitic The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

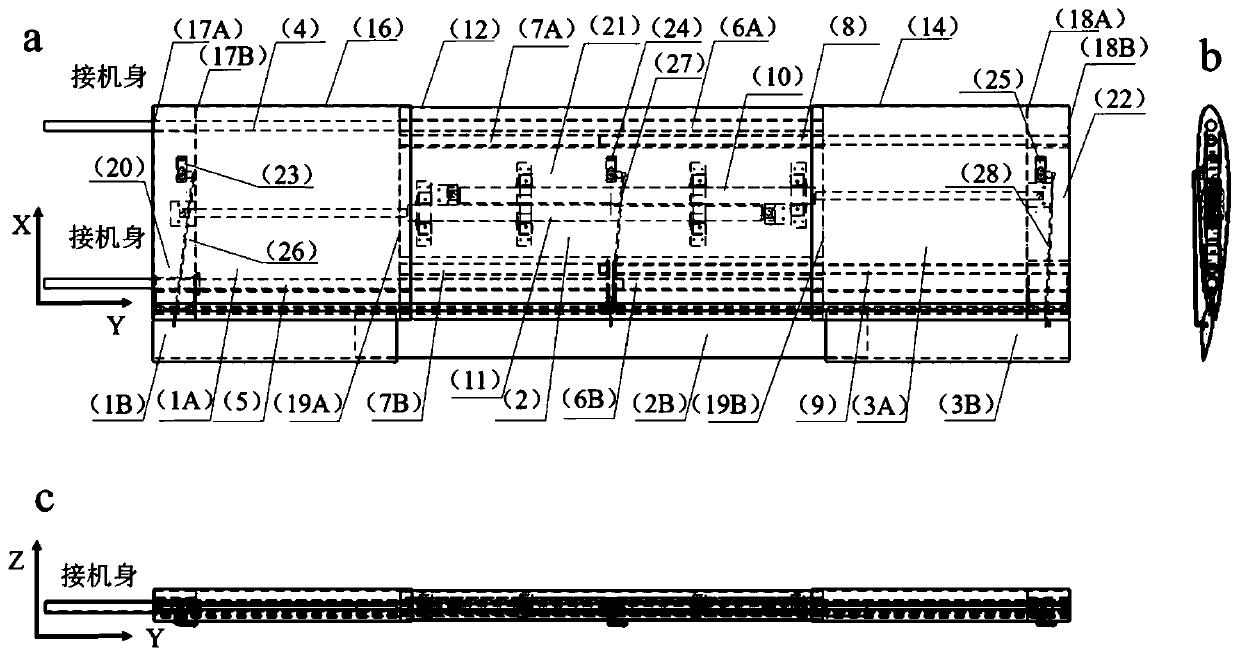

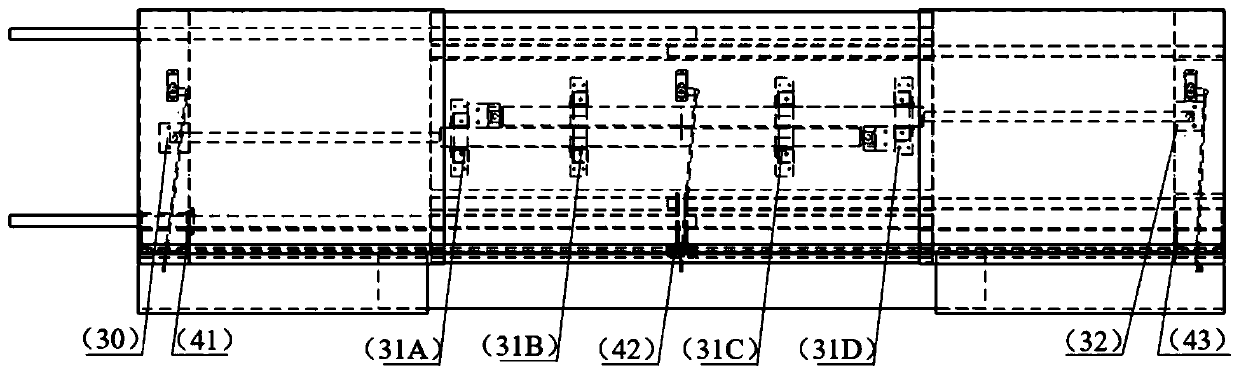

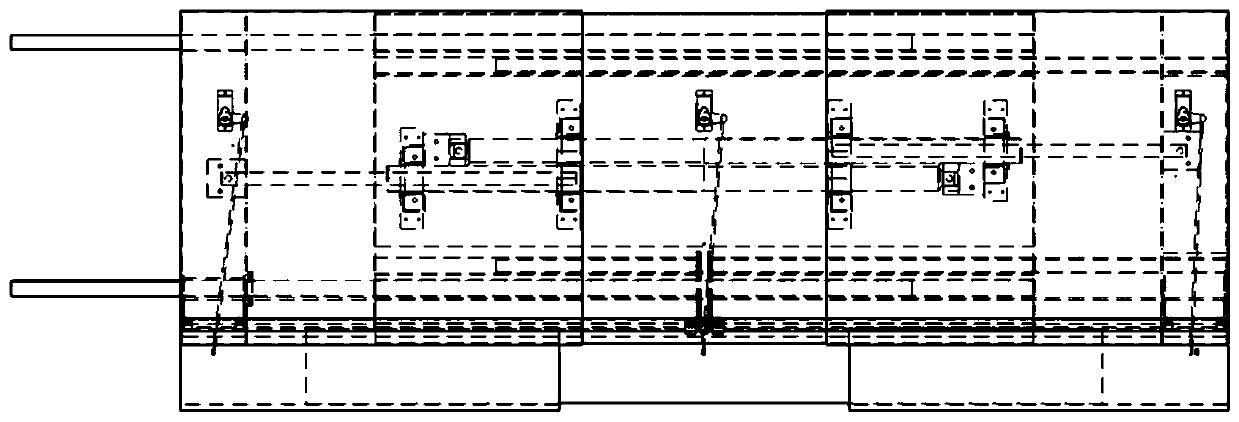

[0039] The purpose of the present invention is to provide a set of mechanisms for changing the length of the wings by stretching and retracting, and changing the curvature of the airfoil by retracting and retracting the flaps, so that the aircraft equipped with the wings can have good high-speed and low-speed performance. The detailed description is combined with the abstract drawings and Figure 1~6 illustrate.

[0040] The wing is a three-stage retractable wing mechanism, and each section of the wing includes a main wing and a flap. It specifically includes the inner main wing 1A; the outer main wing 3A; the middle main wing 2A nested between the inner main wing 1A and the outer main wing 3A; the inner flap 1B hinged with the inner main wing 1A; and the outer main wing 3A hinged The outer flap 3B of the outer section; the middle section flap 2B nested between the inner section flap 1B and the outer section flap 3B and hinged with the middle section main wing 2A; respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com