Office storage box convenient to move

A technology for convenient movement and storage boxes, which is applied to the parts of bottles/cans, rigid containers, containers, etc., which can solve the problems of poor mobility of office storage boxes and achieve the effect of reducing bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

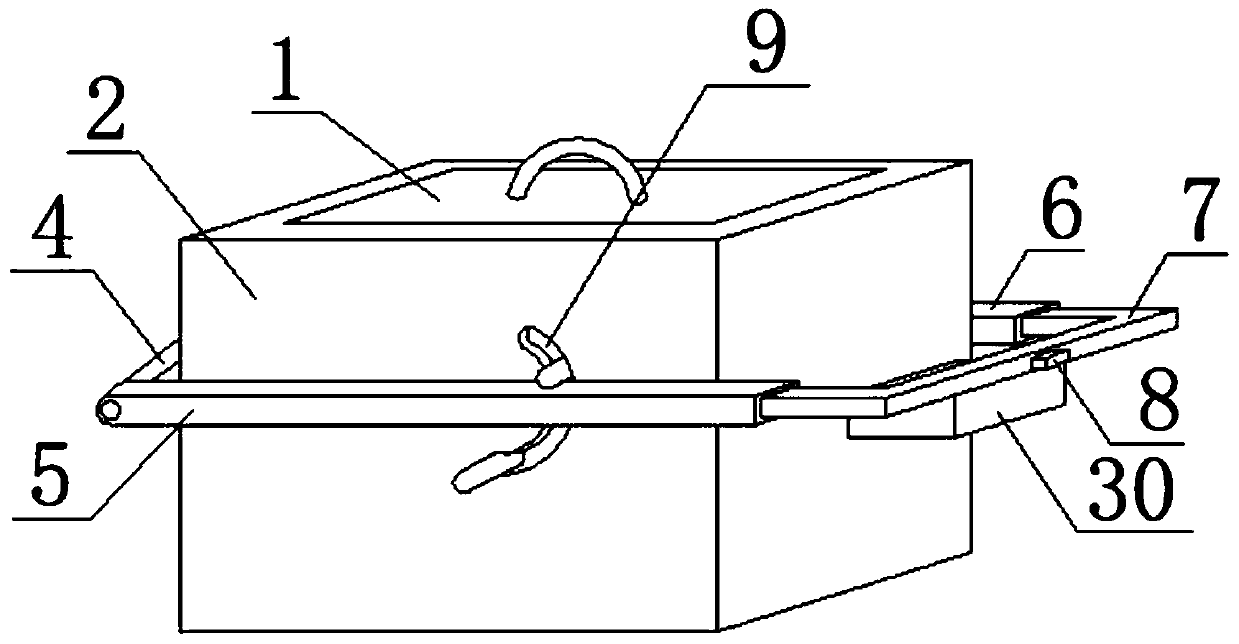

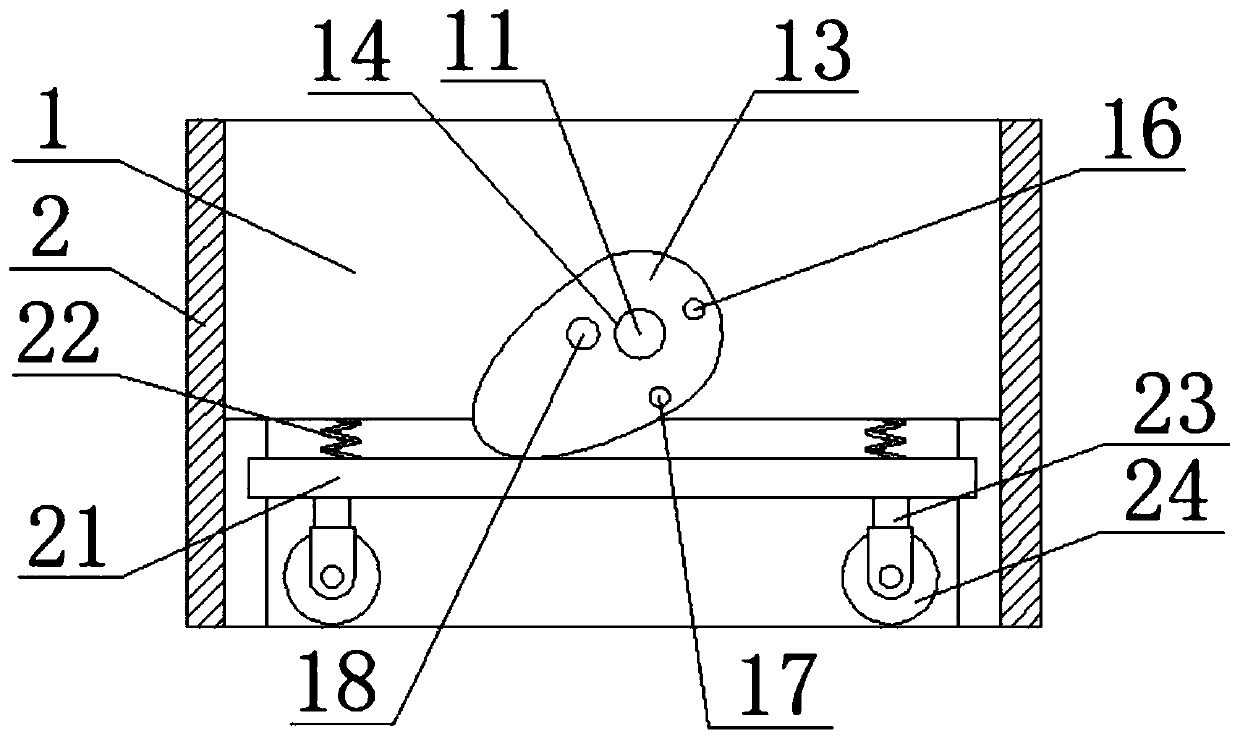

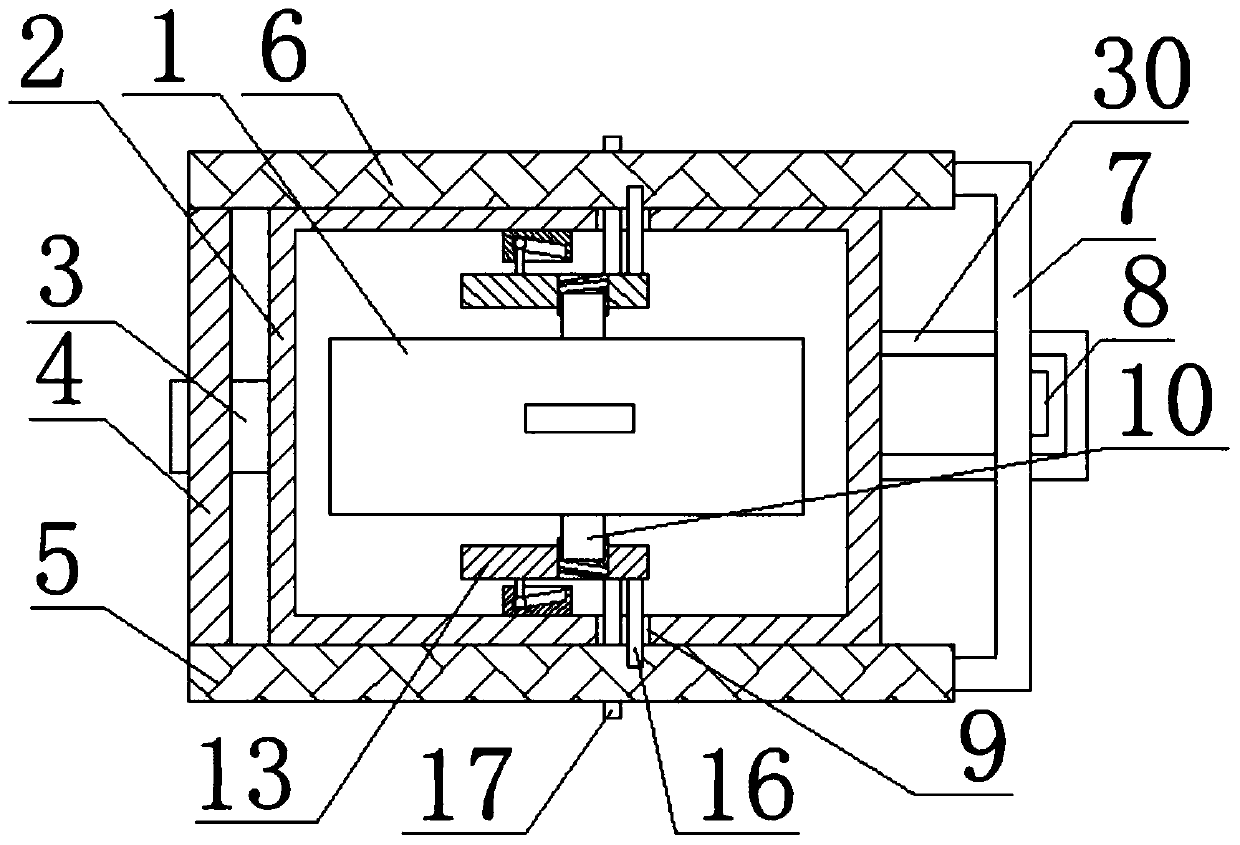

[0033] refer to Figure 1-9 , a convenient mobile office storage box, including a storage box body 1, the side of the storage box body 1 is fixedly provided with a shell 2, the shape of the shell 2 is irregular, so that the shell 2 and the storage box body 1 are partially connected Under normal circumstances, there is a gap between the shell 2 and the storage box body 1, and one side of the shell 2 is fixedly installed with a fixing base 3, and a third through hole is opened on the fixing base 3, and a cross bar 4 is fixedly installed in the third through hole. The first connecting rod 5 and the second connecting rod 6 are respectively rotated at both ends of the cross bar 4, and the first connecting rod 5 and the second connecting rod 6 are provided with a first chute and a second chute respectively. The chute and the second chute are jointly slidably installed with the same pull rod 7, and the side of the shell 2 away from the fixed seat 3 is fixedly equipped with a pull rin...

Embodiment 2

[0044] refer to Figure 1-9 , a convenient mobile office storage box, including a storage box body 1, the side of the storage box body 1 is fixedly provided with a shell 2, the shape of the shell 2 is irregular, so that the shell 2 and the storage box body 1 are partially connected Under normal circumstances, there is a gap between the shell 2 and the storage box body 1, and a fixed seat 3 is welded on one side of the shell 2, and a third through hole is opened on the fixed seat 3, and a cross bar 4 is welded in the third through hole, and the horizontal bar 4 is welded in the third through hole. The first connecting rod 5 and the second connecting rod 6 are respectively rotated at the two ends of the rod 4, and the first connecting rod 5 and the second connecting rod 6 are respectively provided with a first chute and a second chute, and the first chute The same pull rod 7 is installed jointly with the second chute, and the side of the shell 2 away from the fixed seat 3 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com