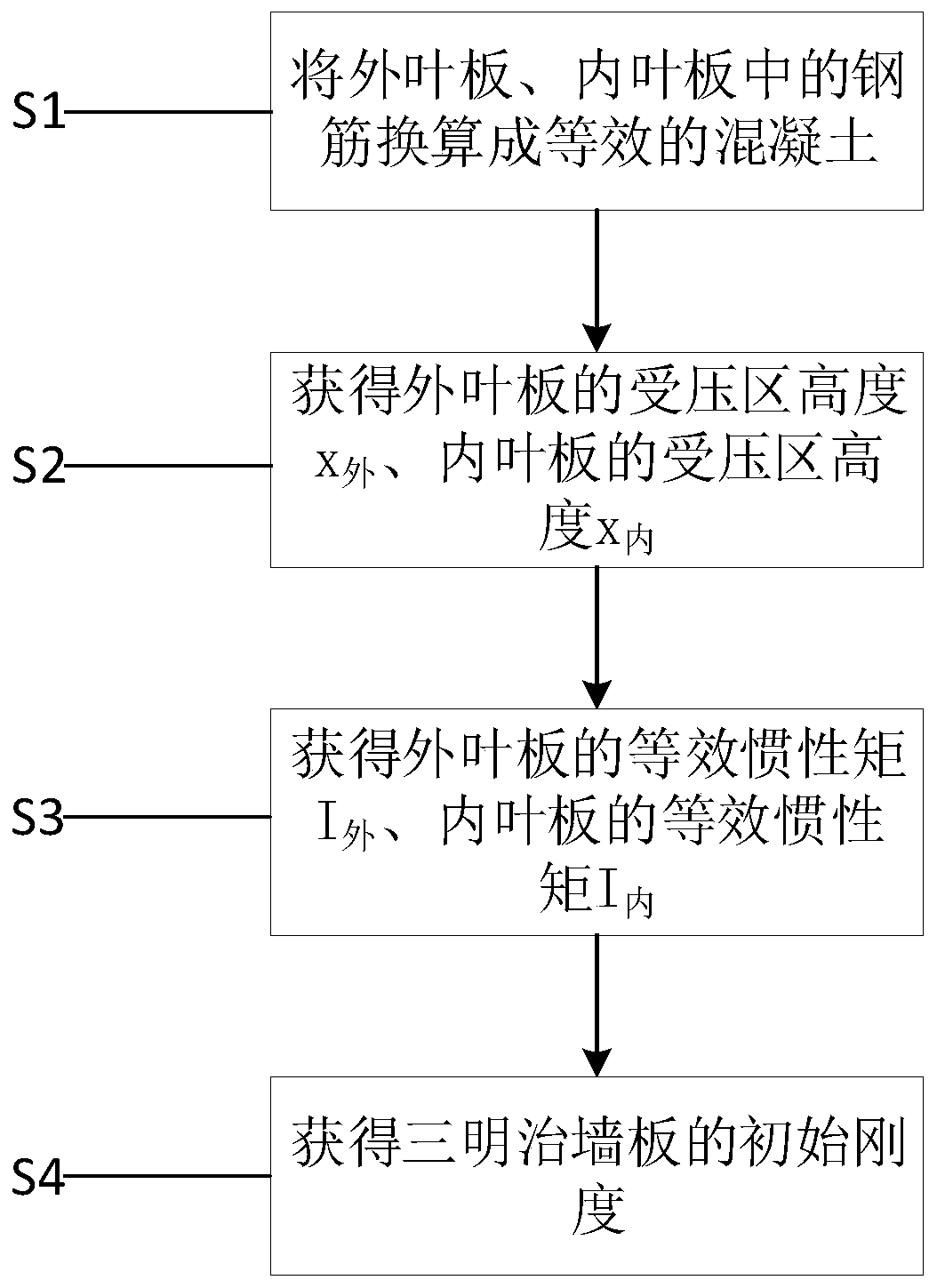

Method for calculating initial rigidity of sandwich wallboard

A technology of initial stiffness and calculation method, applied to walls, using stable tension/pressure to test the strength of materials, building components, etc. The process is simple, manpower saving, and the effect of simplified calculation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in detail below in conjunction with specific embodiments.

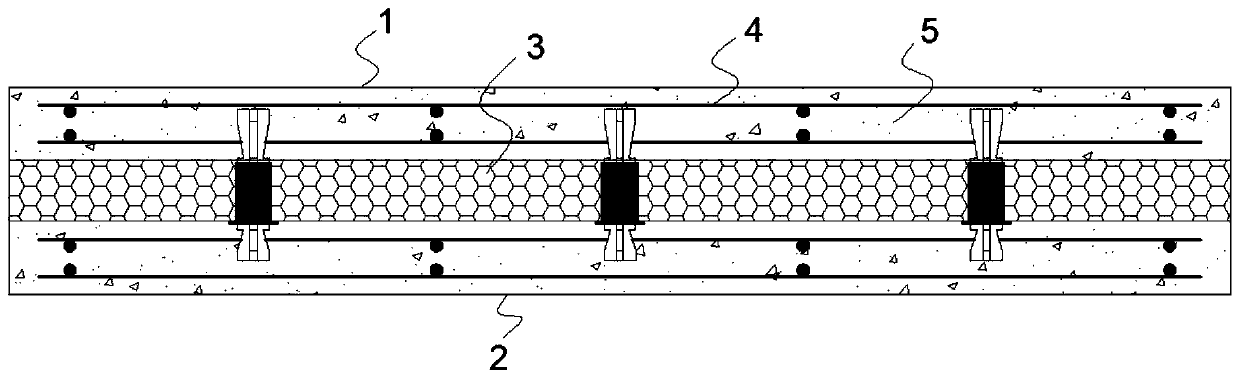

[0065] by Figure 5 The sandwich wallboard shown is taken as an example. The parameters of the wallboard have been indicated in the figure, and the unit is mm. Known concrete elastic modulus E c =3.25×10 4 MPa, steel elastic modulus E s =2.0×10 5 MPa, reinforcement area A' in compression zone of inner (outer) slab s =0mm 2 , Area A of reinforcement in the tensile zone of the inner (outer) slab s =550mm 2 .

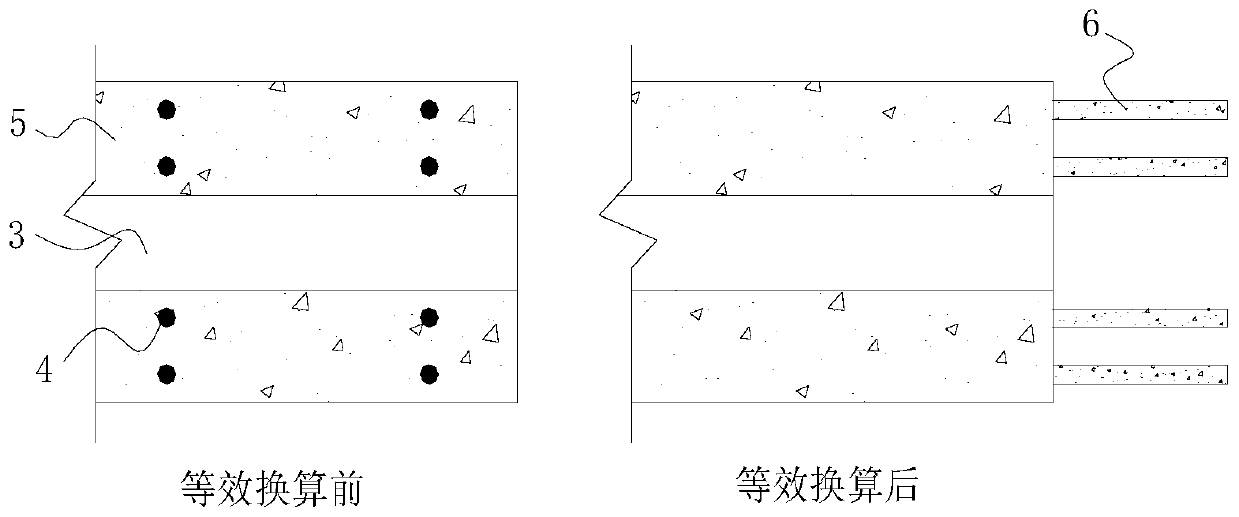

[0066] By step S1,

[0067] The steel bars in the outer leaf plate and inner leaf plate are converted into equivalent concrete,

[0068] Conversion formula for reinforcement in the compression zone of the outer leaf plate:

[0069] A' 外 =nA' s外

[0070] A' 外 Indicates the area of steel bars in the compression zone of the outer leaf plate converted into equivalent concrete, A’ s外 Indicates the reinforcement area in the compression zone of the outer le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com