Analysis method for three-dimensional visual structure of asphalt mixture based on 3D printing

A technology of asphalt mixture and analysis method, which is applied in the direction of material analysis, analysis materials, and measurement devices using wave/particle radiation, which can solve the problems of breakthrough in printing process, high cost, and limited types of printing materials, etc., and achieve printing The effect of precise and efficient process and high geometric similarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

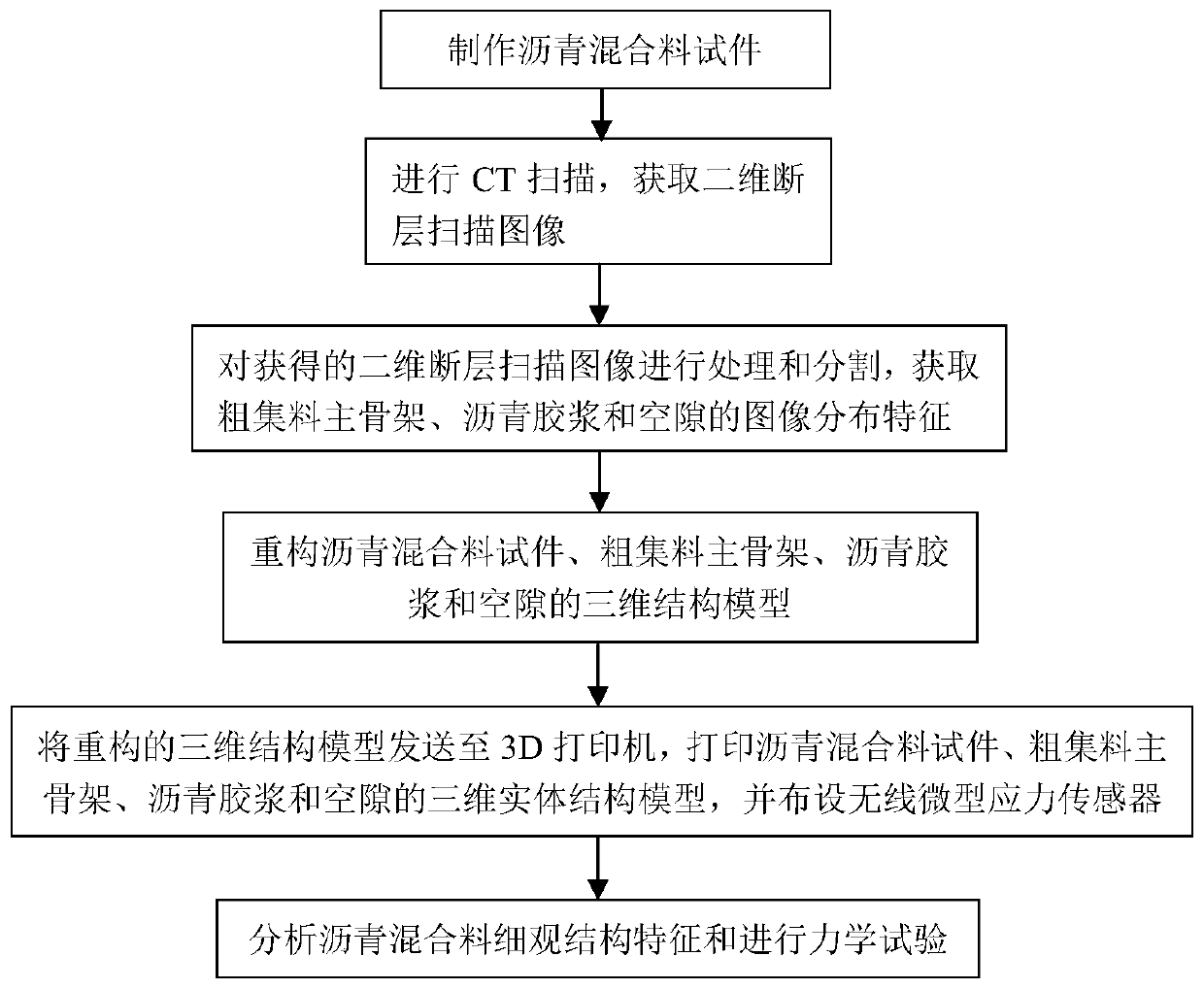

[0033] This embodiment is an analysis method based on the 3D visualization structure of 3D printed asphalt mixture, and its process is as follows figure 1 shown, including the following steps:

[0034] S1, making asphalt mixture test specimens indoors; asphalt mixture test specimens include but not limited to Marshall test specimens and / or rotary compaction test specimens.

[0035] Marshall test piece Standard test piece (double-sided compaction 75 times): a cylinder with a diameter of 101.6mm×63.5mm, suitable for standard Marshall test and indirect tensile test;

[0036] Rotary compaction test piece: The sample diameter is 150mm or 100mm, suitable for measuring the physical and mechanical properties of asphalt mixture.

[0037] S2, CT scan the asphalt mixture specimen to obtain continuous two-dimensional tomographic images; when CT scanning the asphalt mixture specimen, set the scanning interval, and scan continuously along the longitudinal direction of the asphalt mixture s...

Embodiment 2

[0054] In this embodiment, an analysis method based on the 3D visualization structure of 3D printed asphalt mixture includes the following steps:

[0055] S1. According to the asphalt mixture gradation required for mechanical tests, make a standard Marshall test piece for indoor testing. The compaction standard is double-sided compaction 75 times, and the size of the test piece is a cylinder with a diameter of 101.6mm×63.5mm.

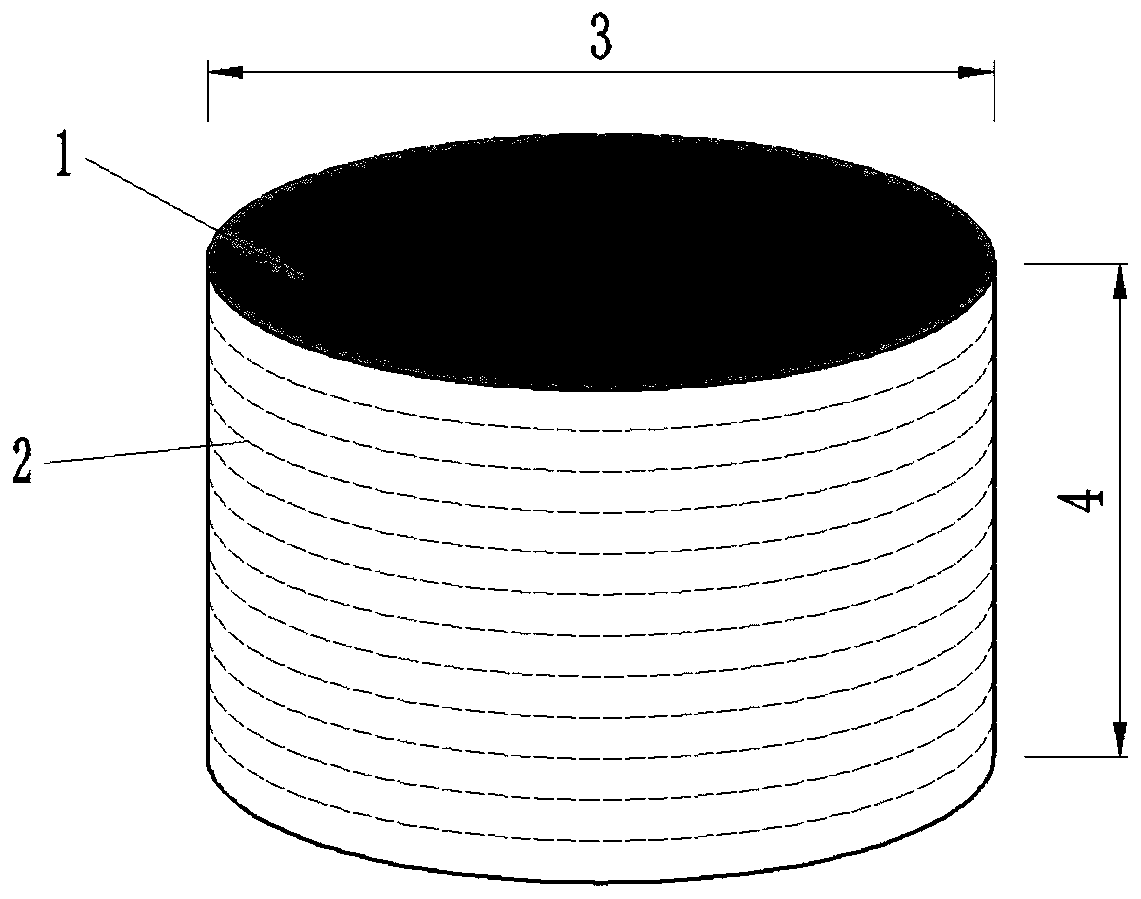

[0056] S2. Carry out CT scanning on the Marshall specimen standard specimen under dry conditions. The CT scan can be carried out by using X-ray three-dimensional microscope and other equipment. Select the rotating scanning mode and scan continuously along the longitudinal direction of the Marshall specimen standard specimen. The scanning distance is set to 0.5mm, such as figure 2 As shown, 126 two-dimensional tomographic images can be obtained for each Marshall specimen standard specimen.

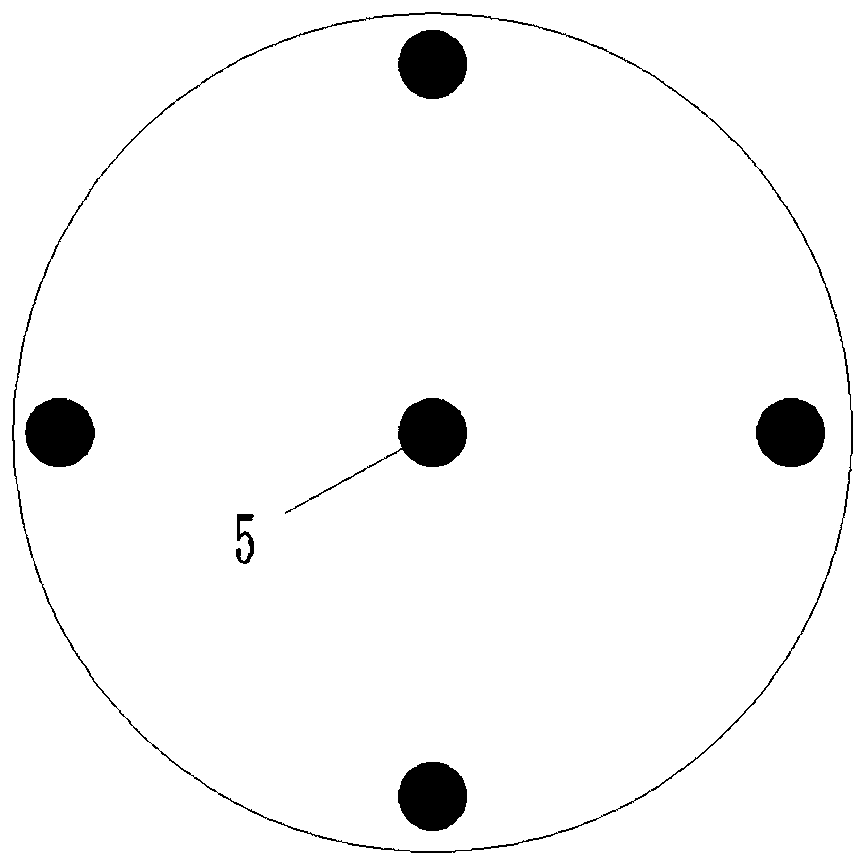

[0057] Step S3, performing filtering and noise reduction and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| greyscale | aaaaa | aaaaa |

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com