Cable with herringbone members and photoelectric composite cable

A photoelectric composite cable and herringbone technology, applied in the field of electric power and cables, can solve problems such as troublesome production, decreased production efficiency, and increased product weight, and achieve the effect of fast stripping speed, fast production speed, and fewer components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

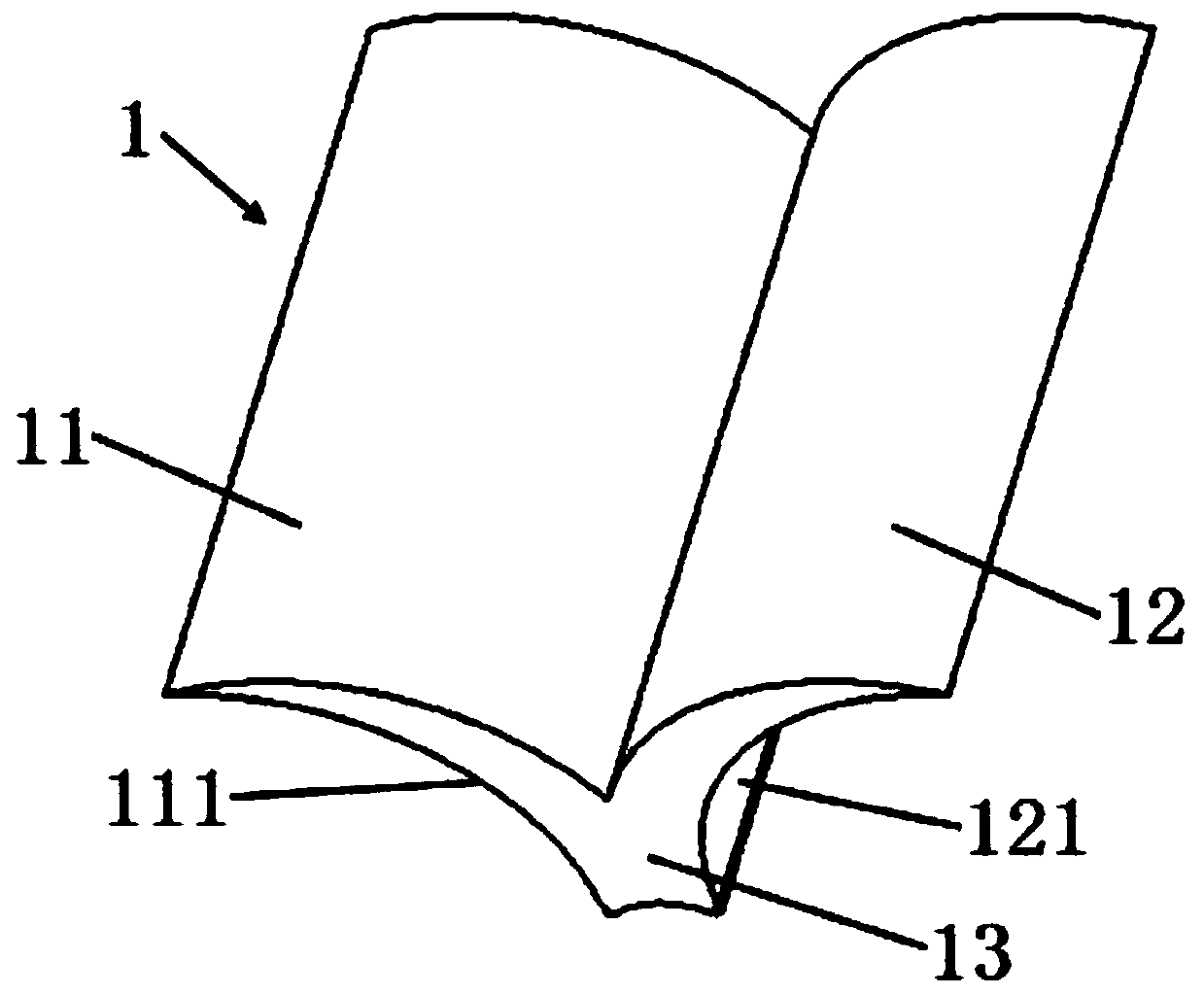

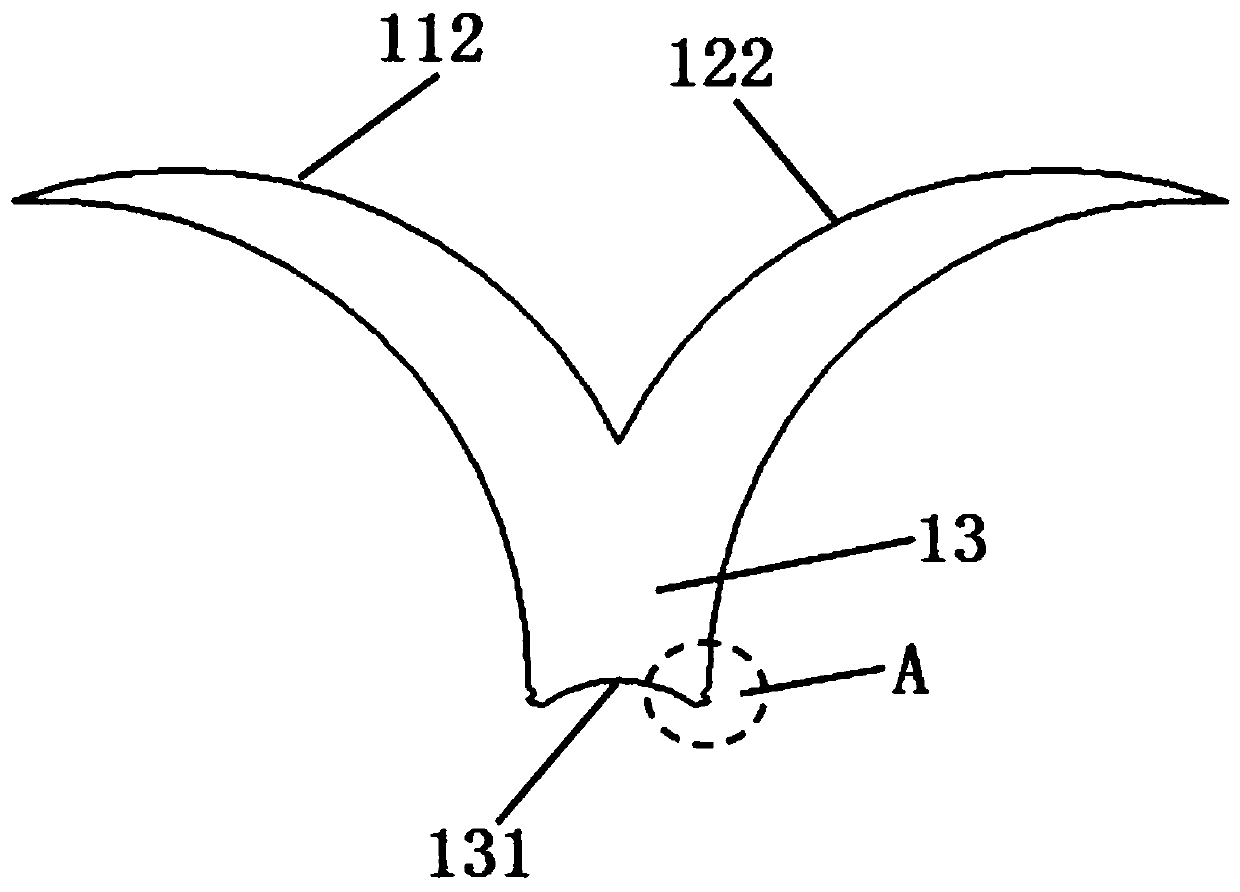

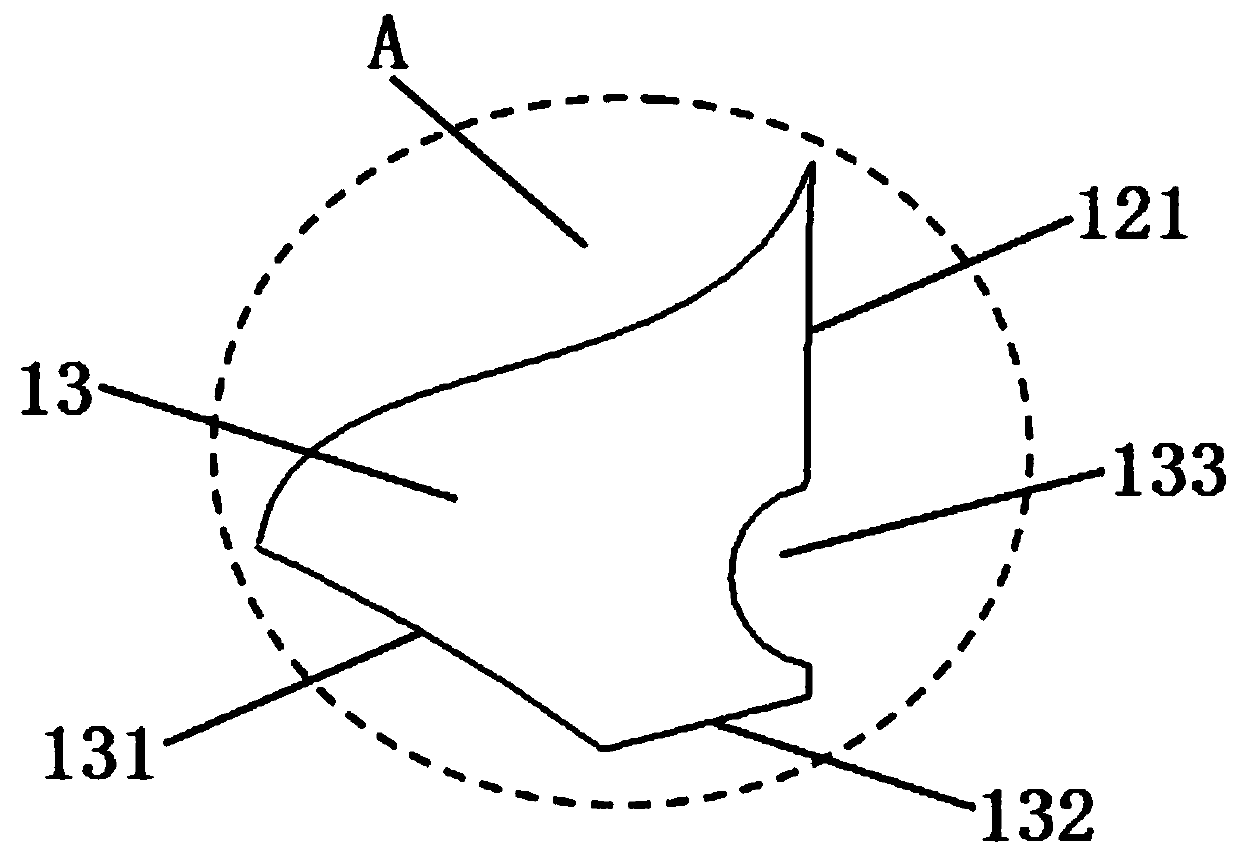

[0035] please see Figure 1 to Figure 8 , a photoelectric composite cable with a herringbone component, with a reinforcing member 2, a filling member 3, an electrical unit 4, an optical unit 5, and an outer sheath 7, and an optical fiber 6 inside the optical unit 5, characterized in that the optoelectronic There are also four chevron-shaped components 1 in the composite cable. The chevron-shaped components 1 are composed of a first bracket 11, a second bracket 12, and a third bracket 13. The first bracket 11 is curved at one end and gradually increases toward the other end. Knife shape, the first bracket inner wall 111 of the first bracket 11 is arc-shaped, the first bracket outer wall 112 of the first bracket 11 is arc-shaped, and the first bracket inner wall 111 and the first bracket outer wall 112 are all protrusions upward; The second bracket 12 is a curved knife shape that is pointed at one end and gradually increases toward the other end. The second bracket inner wall 12...

Embodiment 2

[0038] please see Figure 9 and Figure 10 , and refer to Figure 1 to Figure 8 , a cable with a herringbone member, which has a reinforcement 2, a filler 3, an electrical unit 4, and an outer sheath 7, and is characterized in that the cable also has four herringbone members 1, and the herringbone member 1 It consists of a first bracket 11, a second bracket 12, and a third bracket 13. The first bracket 11 is in the shape of a curved knife with a pointed end and gradually increases toward the other end. The inner wall 111 of the first bracket 11 is arc-shaped. The first bracket outer wall 112 of a bracket 11 is arc-shaped, and the first bracket inner wall 111 and the first bracket outer wall 112 are all convex upwards; the second bracket 12 is in the shape of a curved knife with a pointed end and gradually increasing toward the other end , the second bracket inner wall 121 of the second bracket 12 is arc-shaped, the second bracket outer wall 122 of the second bracket 12 is ar...

Embodiment 3

[0040] please see Figure 11 and Figure 12 , and refer to Figure 1 to Figure 10 , a photoelectric composite cable with a herringbone component, has a reinforcing member 2, a filling member 3, an electrical unit 4, an optical unit 5, and an outer sheath 7, and the optical unit 5 has an optical fiber 6, which is characterized in that the optoelectronic There are also four chevron-shaped components 1 in the composite cable. The chevron-shaped components 1 are composed of a first bracket 11, a second bracket 12, and a third bracket 13. The first bracket 11 is curved at one end and gradually increases toward the other end. Knife shape, the first bracket inner wall 111 of the first bracket 11 is arc-shaped, the first bracket outer wall 112 of the first bracket 11 is arc-shaped, and the first bracket inner wall 111 and the first bracket outer wall 112 are all protrusions upward; The second bracket 12 is a curved knife shape that is pointed at one end and gradually increases towar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com