Patents

Literature

42results about How to "The product is light in weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibacterial deodorant ultra-fine denier polyester raschel blanket and production method thereof

InactiveCN101781830ALong-lasting antibacterial and deodorant functionNot easy to combWarp knittingHeating/cooling textile fabricsUltra fineMoisture

The invention provides an antibacterial deodorant ultra-fine denier polyester raschel blanket and a production method thereof. The blanket uses antibacterial deodorant polyester fiber with the fineness of below 1 denier as blanket fluff yarn raw material and uses 100 to 150-denier polyester filaments as base cloth. The production method of the raschel blanket is characterized by sequentially comprising the following steps: a) preparing the raw material according to the formula; b) weaving the raw material into grey cloth; c) slitting the grey cloth into specification size; d) performing printing or dyeing; e) performing post-treatment, f) performing heat setting; g) performing combing; and h) performing shearing to obtain a finished blanket. Compared with the prior art, the blanket has the advantages of changing the water-repellent non-breathable performance of polyester fiber, selecting and developing appropriate moisture-absorbing sweat-discharging softener and achieving firm moisture-absorbing sweat-discharging function through after-finishing after washing. In order to achieve the fluff style of raschel blankets, an ultra-fine fiber polyester blanket with the fineness of below 1 denier needs to have the moisture-absorbing sweat-discharging function with such fine fiber, as well as fine soft fluff, fluffy straight fluff, bright clean smooth fluff surface, good compression-resisting rebounding property, light weight and good warmth retention property, and similar products cannot achieve the effect.

Owner:宁波西田信染织有限公司

Degradable material, preparation method and application

The invention relates to a degradable material and a preparation method. Biomass resources are used as raw materials, are mixed with auxiliary materials and are placed into a mold to be sterilized, then, microbes are inoculated for culture, and the degradable material can be obtained through drying. The production raw materials of the degradable material have rich sources and low price, no three waste is generated in the production process, and the environment is not polluted. Products produced by using the technical scheme of the invention have the advantages that the weight is light, the pressure-resistance intensity and shock-resistance intensity are good, the damp-proof and mildew-proof effects are realized, in addition, the degradation is easy, the degradable material can be recovered to be used as organic fertilizers after being degraded, and the degradable material is suitable for industrial production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

Breath-freshening pericarp candy and preparation method thereof

InactiveCN103404682AIncrease the variety of deep-processed productsGive full play to the value of goodsConfectionerySweetmeatsFood flavorMalic acid

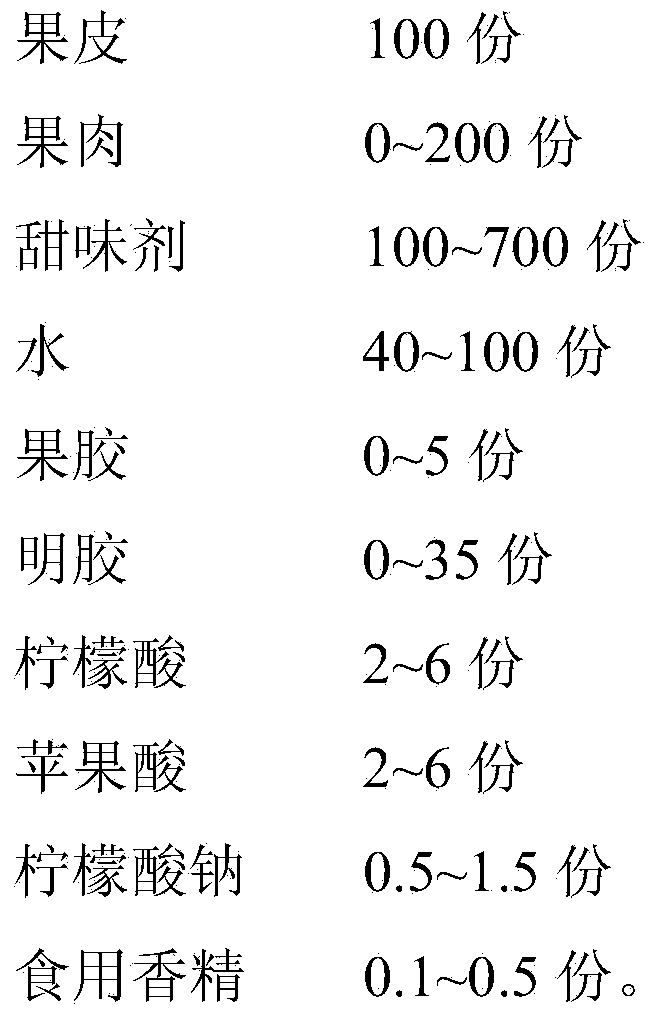

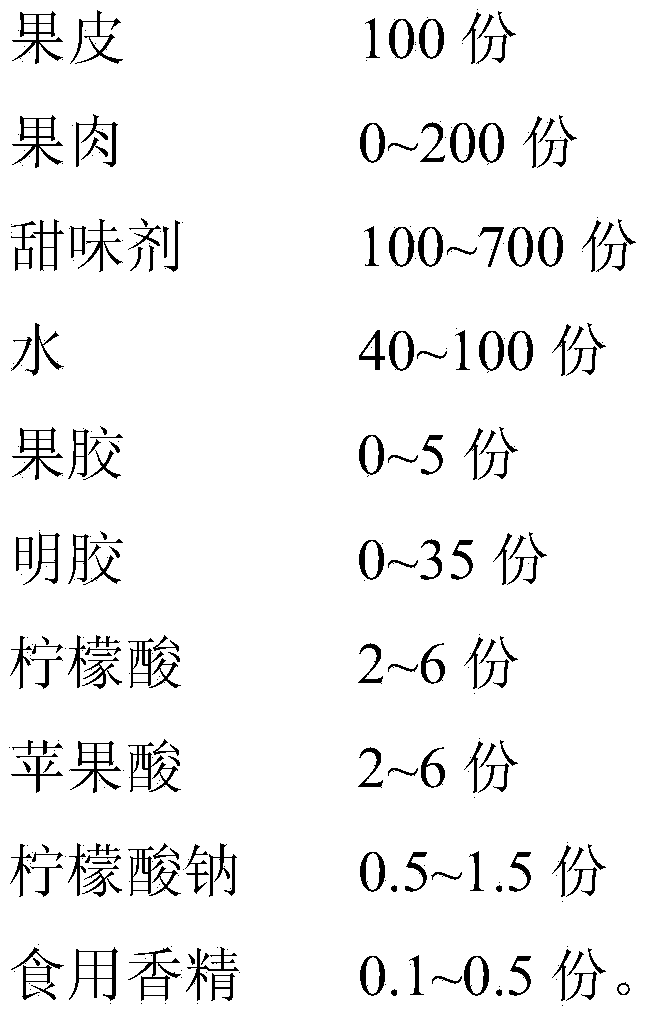

The invention belongs to the technical field of candy preparation and discloses a breath-freshening pericarp candy and a preparation method thereof. The breath-freshening pericarp candy comprises, by weight, 100 parts of pericarp, 0-200 parts of pulp, 100-700 parts of a sweetener, 40-100 parts of water, 0-5 parts of pectin, 0-35 parts of gelatin, 2-6 parts of citric acid, 2-6 parts of malic acid, 0.5-1.5 parts of sodium citrate and 0.1-0.5 parts of edible essence. The breath-freshening pericarp candy has a fresh fruit fragrance, a sour-sweet taste, good elasticity and good chewiness. Pericarp having colors from golden yellow to pale yellow and from dark green to light green is uniformly distributed in translucent candy so that colors are bright and appearance is good. The breath-freshening pericarp candy has a unique pericarp fragrance, a soft and glutinous taste, chew resistance, a sweet taste and no bitter and astringent taste. The pericarp and the candy of the breath-freshening pericarp candy can be eaten. The breath-freshening pericarp candy has a unique local flavor and is a slag-free breath-freshening candy.

Owner:范瑞 +1

Method for large-scale production of emboss decorative paintings

InactiveCN103481723AReduce process linksHigh degree of mechanizationDecorative surface effectsSpecial ornamental structuresMolding (decorative)Manufacturing engineering

The invention belongs to the field of ornaments, and particularly relates to a method for large-scale production of emboss decorative paintings. The method mainly comprises the following processes: (1) selecting a material; (2) molding; (3) forming; (4) performing surface treatment; (5) adhering a bottom plate and mounting. The method has the advantages of fewer processes, high degree of mechanization, short production period, light product weight, high image quality and the like.

Owner:邓启文

Comprehensive utilization method for recycling manganese oxide slag

ActiveCN101543830AHigh recycling valueAchieving zero emissionsSolid waste managementSolid waste disposalLand resourcesSlag

The invention relates to a comprehensive utilization method for recycling manganese oxide slag. The method comprises the following steps: (1) screen separation; (2) dilution and agitation; (3) integrated separation; (4) dehydrating and drying; (5) package; and (6) repreparation of cement retarder or mixing and pressing of walling material or repreparation of slag cement. The method has the advantages that about 30 percent of manganese oxide concentrate (content of manganese metal is over 30 percent), iron and other heavy metals in the manganese oxide slag are recycled by using integrated separation technology, and the secondary tailing part remained after the integrated separation replaces plaster to be the cement retarder, or the walling material, or the slag cement; and the method can fundamentally solve the problem of the pollution on the environment caused by the manganese oxide slag, make full and reasonable use of the resources in the manganese oxide slag, save land resource, improve the comprehensive utilization value of the manganese oxide slag and realize zero discharge of the manganese oxide slag.

Owner:广西润华环保科技有限公司

Low-phosphorus whey protein powder suitable for patients with chronic nephrosis, and preparation method of low-phosphorus whey protein powder

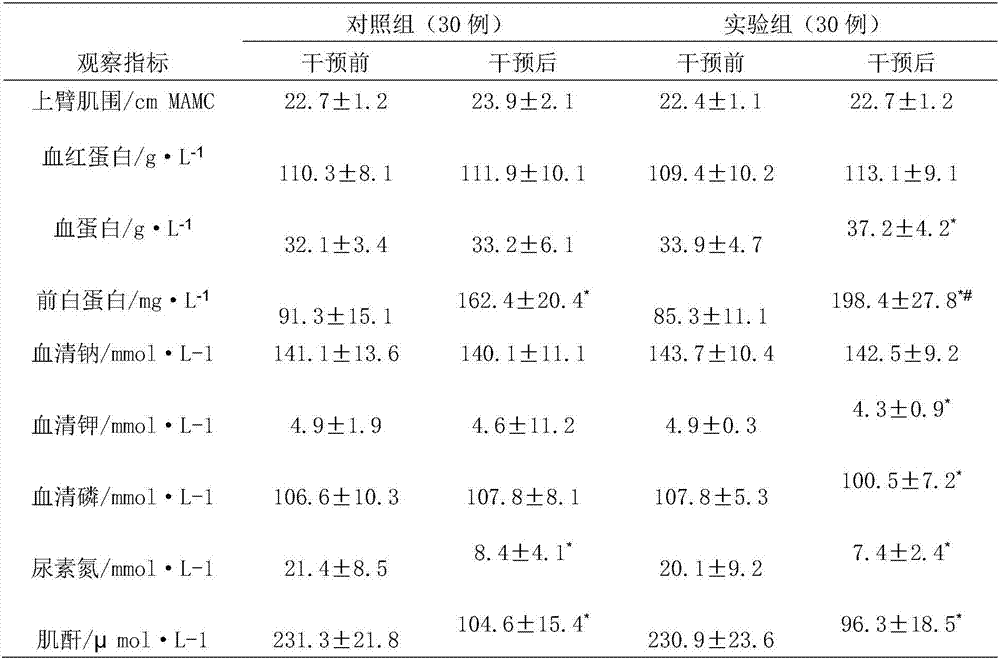

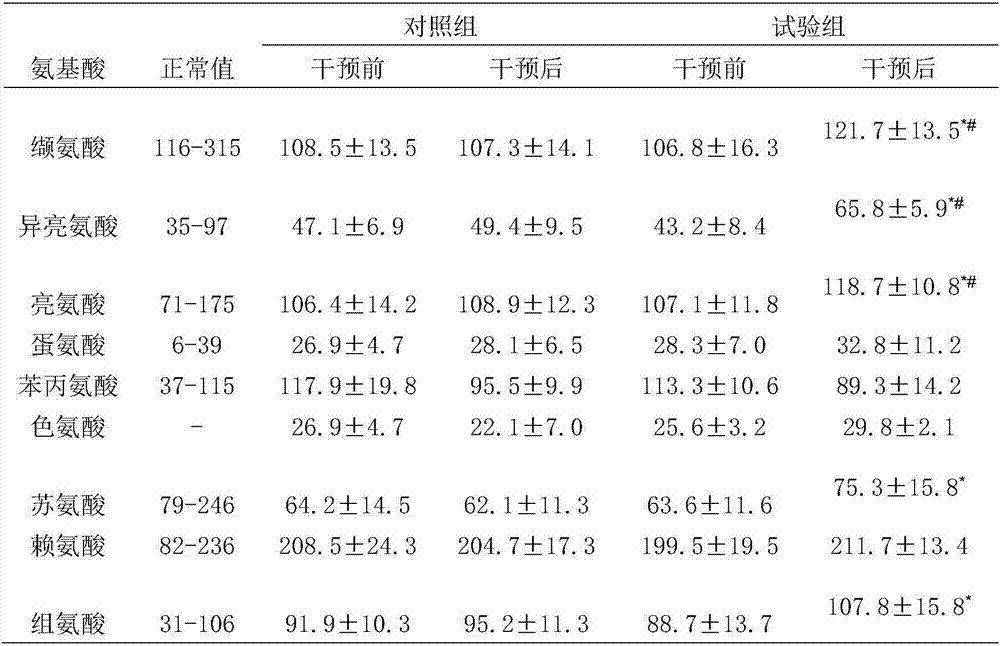

The invention provides low-phosphorus whey protein powder suitable for patients with chronic nephrosis. After the technical scheme is adopted, a brand new protein powder formula is designed aiming at the constitutional characteristics of the patients with the chronic nephrosis, so that the contents of phosphorus and potassium elements in a protein source are improved on one hand, and appropriate microelements are matched for the situation of nutritional disorder of the patient with the chronic nephrosis and especially for patients accepting dialysis therapy on the other hand; the low-phosphorus whey protein powder aims at avoiding the occurrence of hyperphosphatemia on the basis of replenishing high quality protein for the patients with the nephrosis, and improves the nutritional status of the patients with the nephrosis and promotes the physical recovery of the patients with the nephrosis at the same time. The product provided by the invention can help to improve the tolerance of the patients during treatment, reduce morbidity and mortality, improve the living quality of the patients, and the like. On this basis, a preparation method of the low-phosphorus whey protein powder is designed according to the characteristics of the formula materials; the method is carried out in a way of dry blending, and reduces the energy consumption by limiting the feeding sequence and the feeding amount; the obtained product is light in weight, good in water solubility and complete in nutrient retention.

Owner:中恩(天津)医药科技有限公司

Composite foaming cement self-insulating brick and processing technology thereof

InactiveCN104446193ASimple preparation processReduce weightSolid waste managementCeramicwareSlagBuilding energy

The invention relates to a composite foaming cement self-insulating brick and a processing technology thereof. Pulverized fuel ash, slag, ceramsite, waste polyphenyl granules, other industrial and mineral wastes and light materials are taken as main components, the product weight is greatly reduced, and the building deadweight is reduced. In addition, furnace sintering and stream-pressure oxygenation are not needed during production, high-temperature maintenance is avoided, wastewater, waste gas, waste residues and the like are not produced in the process, the energy consumption is effectively saved, and waste emission is reduced. The process design is simple and reliable, large-scale batch factory production is facilitated, the produced product is high in size uniformity, and the brick is good in appearance smoothness. Therefore, the national requirement on building energy conservation integration is met, the building construction process is simplified, and the total cost of the building is effectively reduced.

Owner:HEZE BAWANG MACHINERY

Environmental-friendly glass fiber reinforced plastic coating material and preparation method thereof

InactiveCN103773089AGood physical propertiesGood mechanical propertiesChemical industryEpoxy resin coatingsCorrosionMethacrylic acid

The invention discloses an environmental-friendly glass fiber reinforced plastic coating material. The environmental-friendly glass fiber reinforced plastic coating material is characterized by being prepared from the following raw materials in parts by weight: 2-3 parts of nano mullite, 28-32 parts of E-12 epoxy resin, 10-12 parts of amino resin, 2-4 parts of 3-pyrroline, 2-3 parts of hexafluoro acetylacetone, 5-8 parts of n-propyl methacrylate, 6-9 parts of zinc naphthenate, 26-29 parts of chopped glass fibers, 2-3 parts of T31 epoxy resin curing agent, 4-6 parts of diepoxy propane ethyl ether, 2-3 parts of nano silica, 1-2 parts of bauxite and 1-2 parts of auxiliaries. According to the coating material, through adding the auxiliaries, the material has good physical properties and mechanical properties, and a reinforcing effect is exerted; the production process of the coating material is simple and reasonable; a formed product has superior corrosion resistance and relatively strong strength property, is lightweight, ageing-resistant, high-temperature resistant, fireproof, flame-retardant, energy-saving and environmental-friendly, and is excellent in insulating performance.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Fish ball food and preparation method thereof

InactiveCN101455414AEasy to storeLong shelf lifeMeat/fish preservationFood preparationFreeze-dryingFood products

The invention discloses a fish ball food and preparation method thereof. The fish ball food preparation method comprises: firstly, making fish ball by traditional handwork method; then, freeze-drying by a food vacuum freeze-drying equipment; finally, taking out under normal temperature condition and obtaining fish ball food. The fish ball food of the present invention achieves the advantages of convenience in preserving eating and carrying, long shelf life and light weight; the invention realizes not only packaging, preserving and transporting under normal temperature condition, but also remote sale, and can promote the modernization, technicalization, industrialization and large scale of the agricultural product operation effectively.

Owner:浙江正心农业开发有限公司

Instant Qiao fish food and preparation method thereof

InactiveCN101455413AEasy to storeLong shelf lifeMeat/fish preservationFood preparationFreeze-dryingFishery

The invention discloses a beaten fish food and preparation method thereof. The beaten fish food preparation method comprises: firstly, making beaten fish by traditional handwork method; then, freeze-drying by a food vacuum freeze-drying equipment; finally, taking out under normal temperature condition, packaging and obtaining beaten fish food. The beaten fish food of the present invention achieves the advantages of convenience in preserving eating and carrying, long shelf life and light weight; the invention realizes not only packaging, preserving and transporting under normal temperature condition, but also remote sale, and can promote the modernization, technicalization, industrialization and large scale of the agricultural product operation effectively.

Owner:浙江正心农业开发有限公司

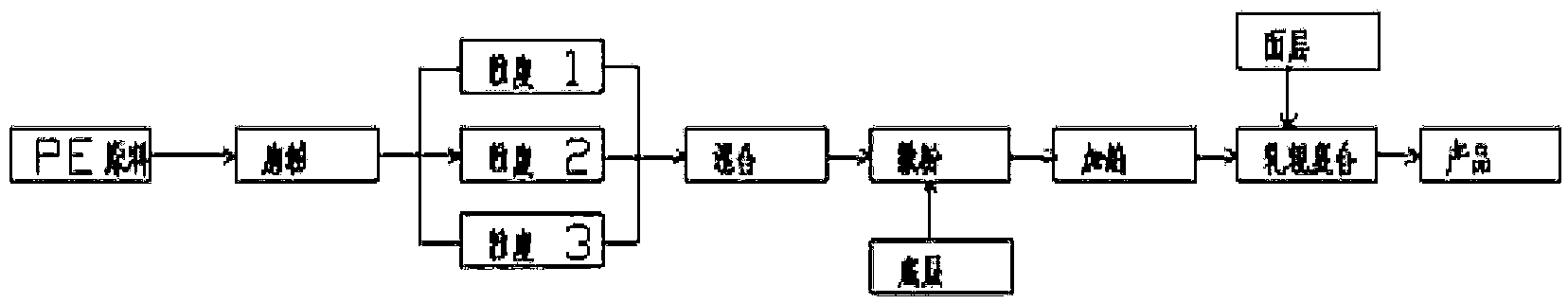

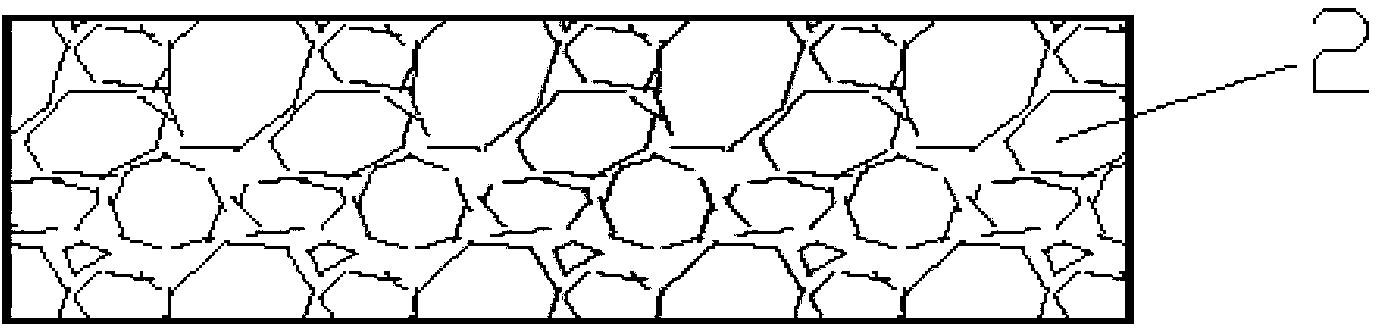

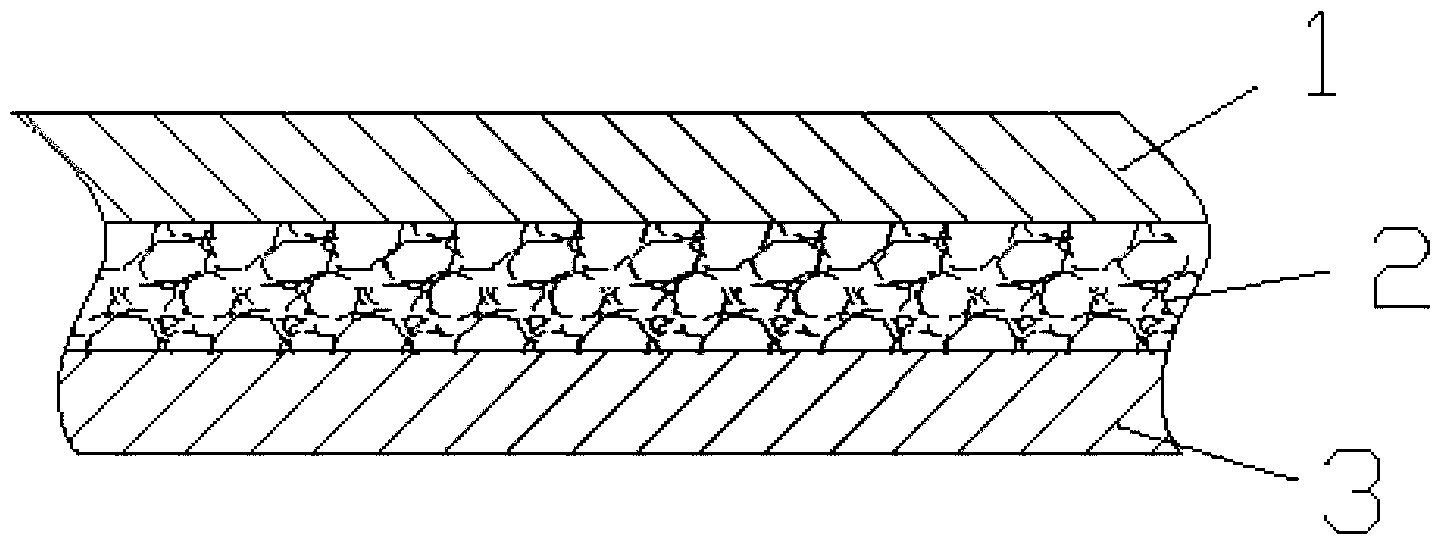

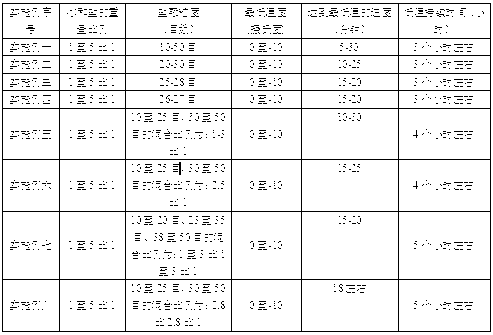

Powder hot-melting and bonding technology of automotive carpet

ActiveCN103275648AReduce noiseReduce weightAdhesive processes with adhesive heatingMetallurgySurface layer

The invention provides a powder hot-melting and bonding technology of an automotive carpet which can produce a good sound-absorbing effect. The technology comprises the steps as follows: a, a polyethylene resin with a low melting point is ground into powder with different particle sizes through a flour mill; b, the powder is divided into fourth classes of less than 400 mu m, 400-600 mu m, 600-1000 mu m and larger than 1000 mu m; c, the powder is mixed according to a weight ratio of 30-50% of the powder with the particle size less than 400 mu m, 20-40% of the powder with the 400-600 mu m particle size , 15-25% of the powder with the 600-1000 mu m particle size and 5-15% of the powder with the particle size larger than 1000 mu m; the mixed powder is sprayed on a surface, required to be bounded, of a surface layer or a bottom layer through a powder sprayer; e, the carpet is dried through a drying oven so as to soften or melt the powder; and f, the surface layer and the bottom layer of the carpet are rolled and bonded through a mill roll.

Owner:扬州新科展纺织制品有限公司

A kind of foamed cement composite self-insulation brick and its processing technology

InactiveCN104446193BImprove insulation effectImprove heat insulationSolid waste managementCeramicwareCement compositesBrick

The invention relates to a composite foaming cement self-insulating brick and a processing technology thereof. Pulverized fuel ash, slag, ceramsite, waste polyphenyl granules, other industrial and mineral wastes and light materials are taken as main components, the product weight is greatly reduced, and the building deadweight is reduced. In addition, furnace sintering and stream-pressure oxygenation are not needed during production, high-temperature maintenance is avoided, wastewater, waste gas, waste residues and the like are not produced in the process, the energy consumption is effectively saved, and waste emission is reduced. The process design is simple and reliable, large-scale batch factory production is facilitated, the produced product is high in size uniformity, and the brick is good in appearance smoothness. Therefore, the national requirement on building energy conservation integration is met, the building construction process is simplified, and the total cost of the building is effectively reduced.

Owner:HEZE BAWANG MACHINERY

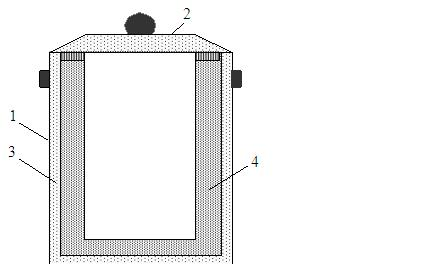

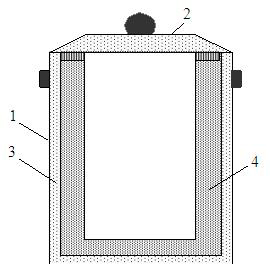

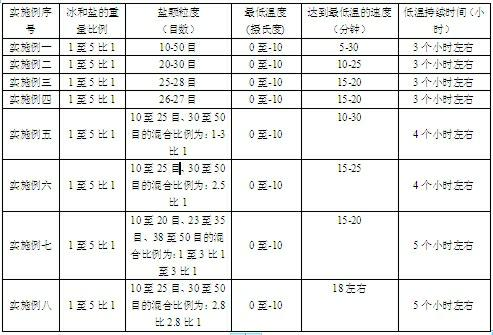

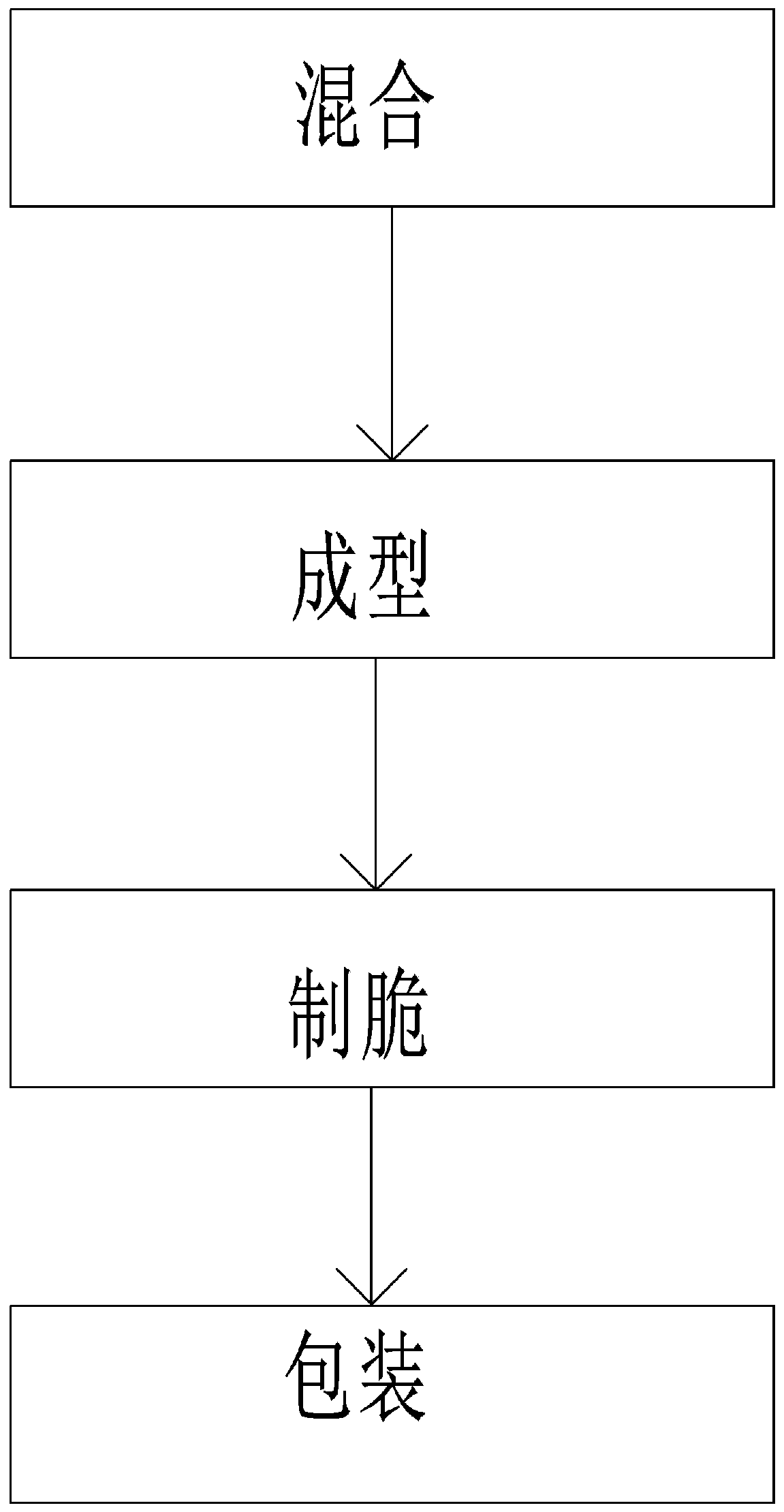

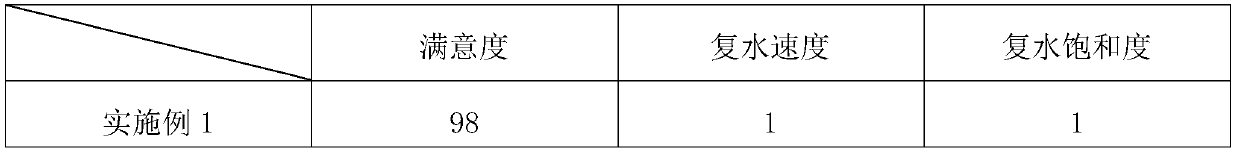

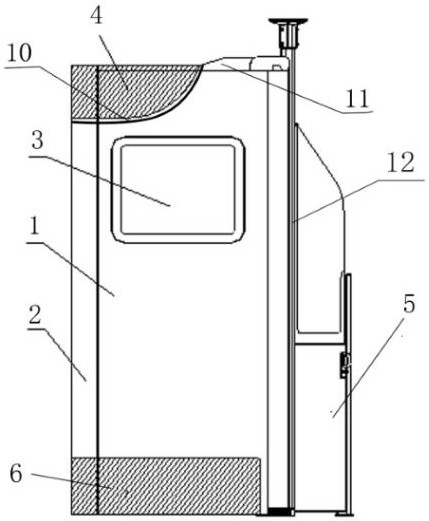

Refrigerant and refrigeration equipment using same

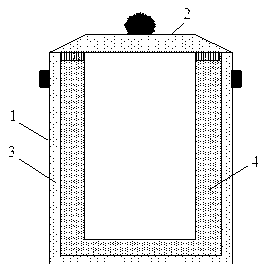

ActiveCN102115664ASmooth meltingAvoid destructionDomestic cooling apparatusLighting and heating apparatusInsulation layerGranularity

The invention relates to a preparation method of a refrigerant and a freezer filled with the refrigerant. The lowering speed of the refrigeration temperature is controlled through the regulation of salt granularity in the components of ice and salt in the refrigerant. The invention also provides the freezer filled with the refrigerant. The freezer comprises a box body provided with a heat insulation layer and a heat insulation cover, wherein, the heat insulation layer is further provided with a freezing interlayer; and the freezing interlayer is used for being filled with the refrigerant. Thesurfaces of blocks of ice are covered with salt particles to facilitate steady melting of the ice and the salt, and different refrigeration effects are achieved according to different mesh numbers ofthe salt particles, thereby solving the problem that the nutrients of food are destroyed by over-quick and unsmooth ice-salt refrigeration temperature change; and the product is light in weight, is easy to popularize in the society, and is simple and practical.

Owner:江苏博悦物联网技术有限公司

Fish ball food and preparation method thereof

InactiveCN101455414BEasy to storeLong shelf lifeMeat/fish preservationFood preparationFreeze-dryingProcess engineering

The invention discloses a fish ball food and preparation method thereof. The fish ball food preparation method comprises: firstly, making fish ball by traditional handwork method; then, freeze-drying by a food vacuum freeze-drying equipment; finally, taking out under normal temperature condition and obtaining fish ball food. The fish ball food of the present invention achieves the advantages of convenience in preserving eating and carrying, long shelf life and light weight; the invention realizes not only packaging, preserving and transporting under normal temperature condition, but also remote sale, and can promote the modernization, technicalization, industrialization and large scale of the agricultural product operation effectively.

Owner:浙江正心农业开发有限公司

Crispy bean curd ball and preparation method thereof

InactiveCN110214823ANo significant change in responsivenessColor unchangedCheese manufactureGlutamine transaminaseSoybean protein

The invention belongs to the field of food processing technology equipment, and particularly discloses a crispy bean curd ball and a preparation method thereof. The crispy bean curd ball comprises 10-20 parts of defatted soybean protein powder, 8-25 parts of soybean oil, 2-5 parts of honey, 6-10 parts of egg white, 0.05-0.5 part of glutamine transaminase and 5-8 parts of starch. The problems thattraditional bean curd is easy to break, likely to rot and not easy to carry and popularize are solved.

Owner:闫润明

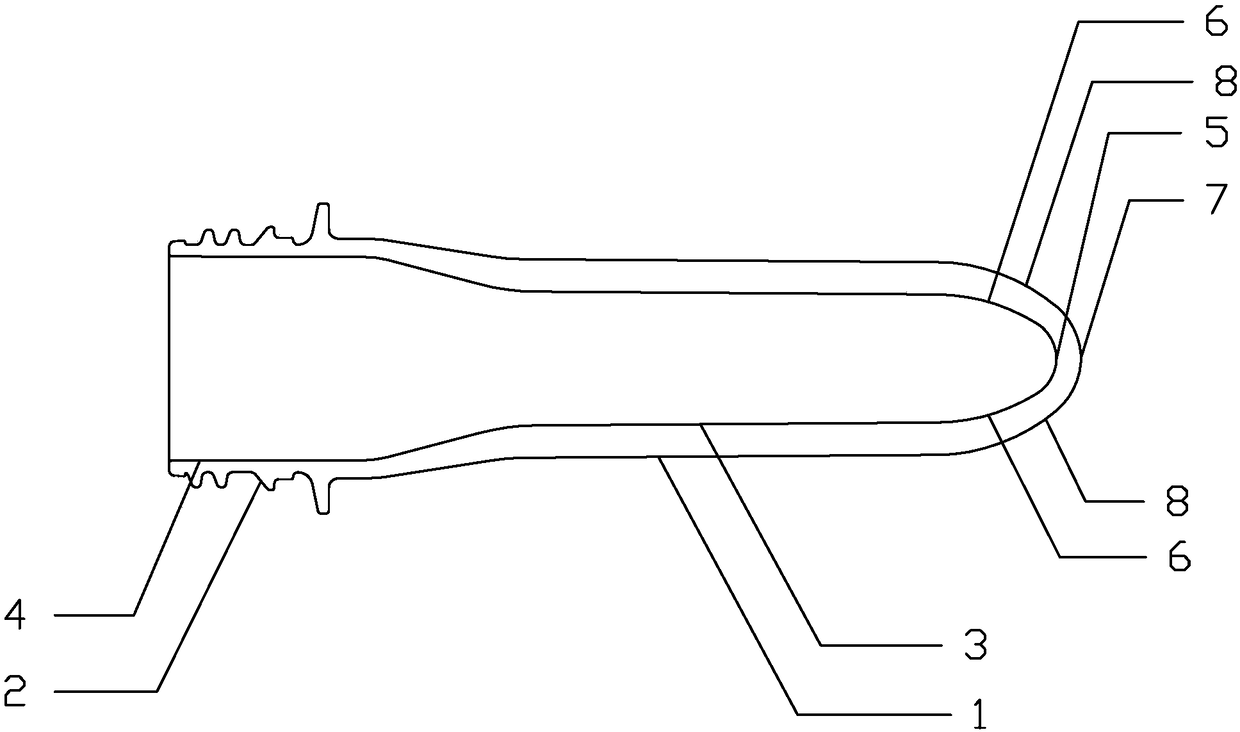

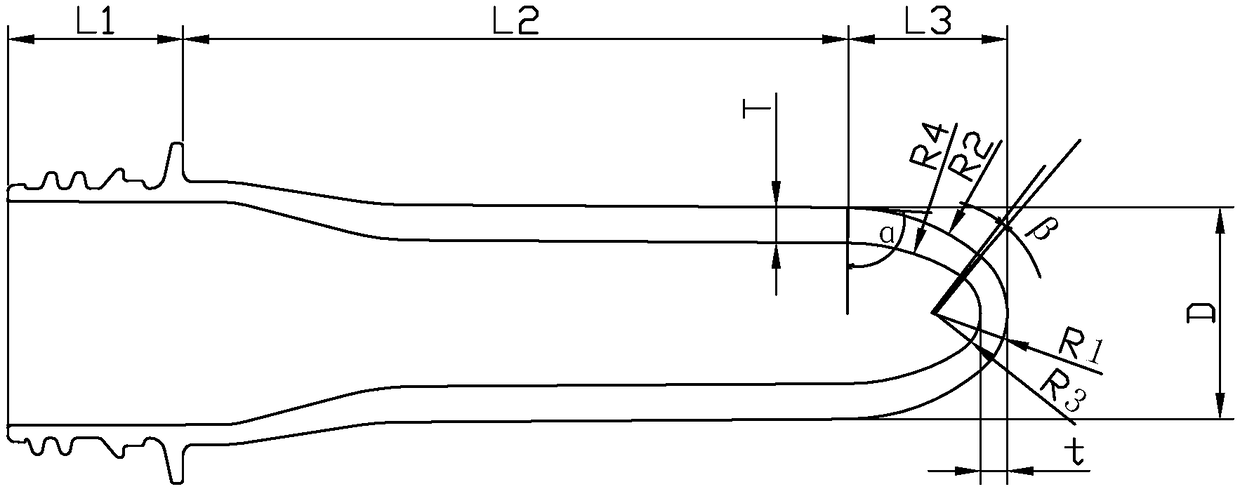

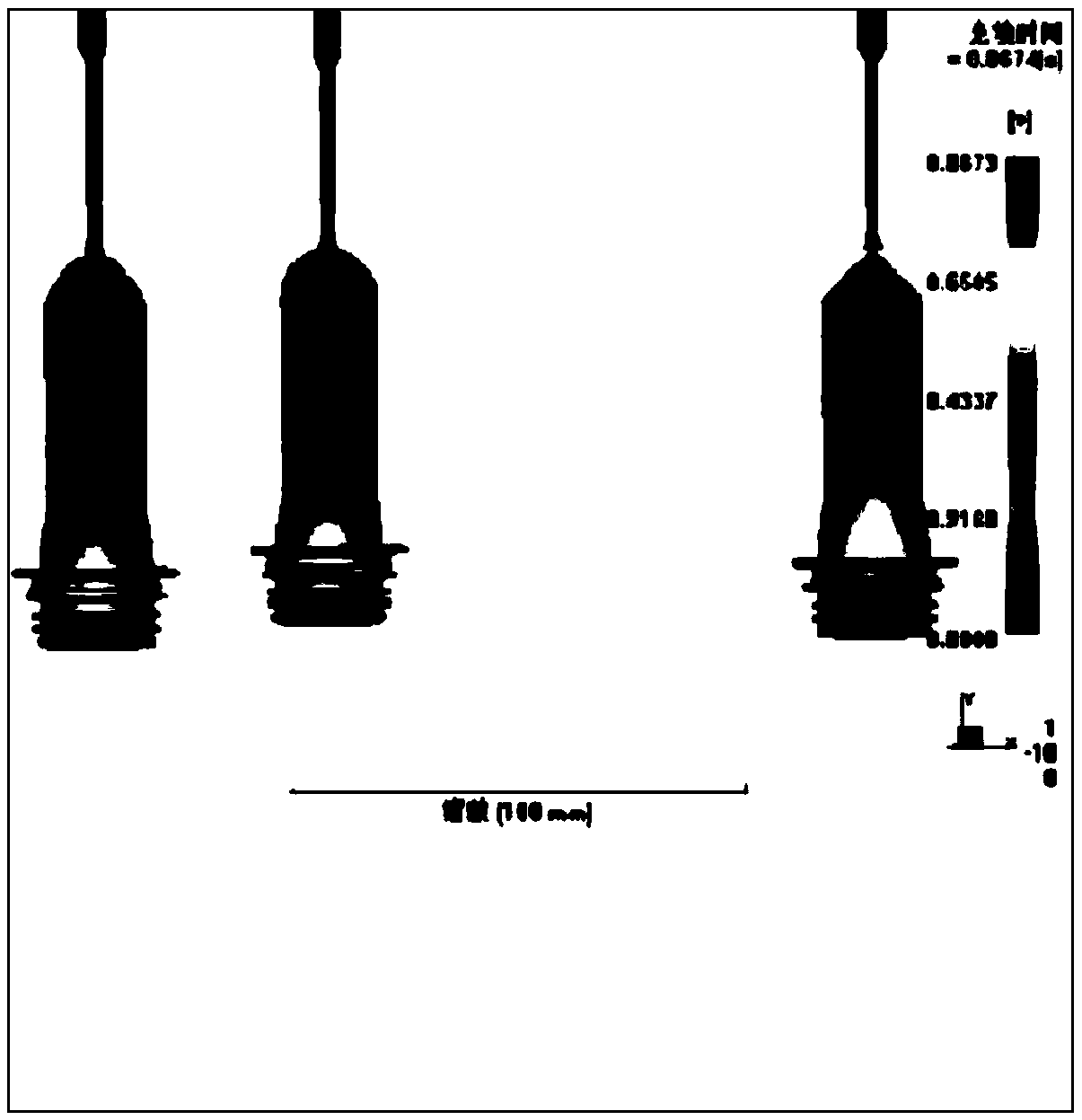

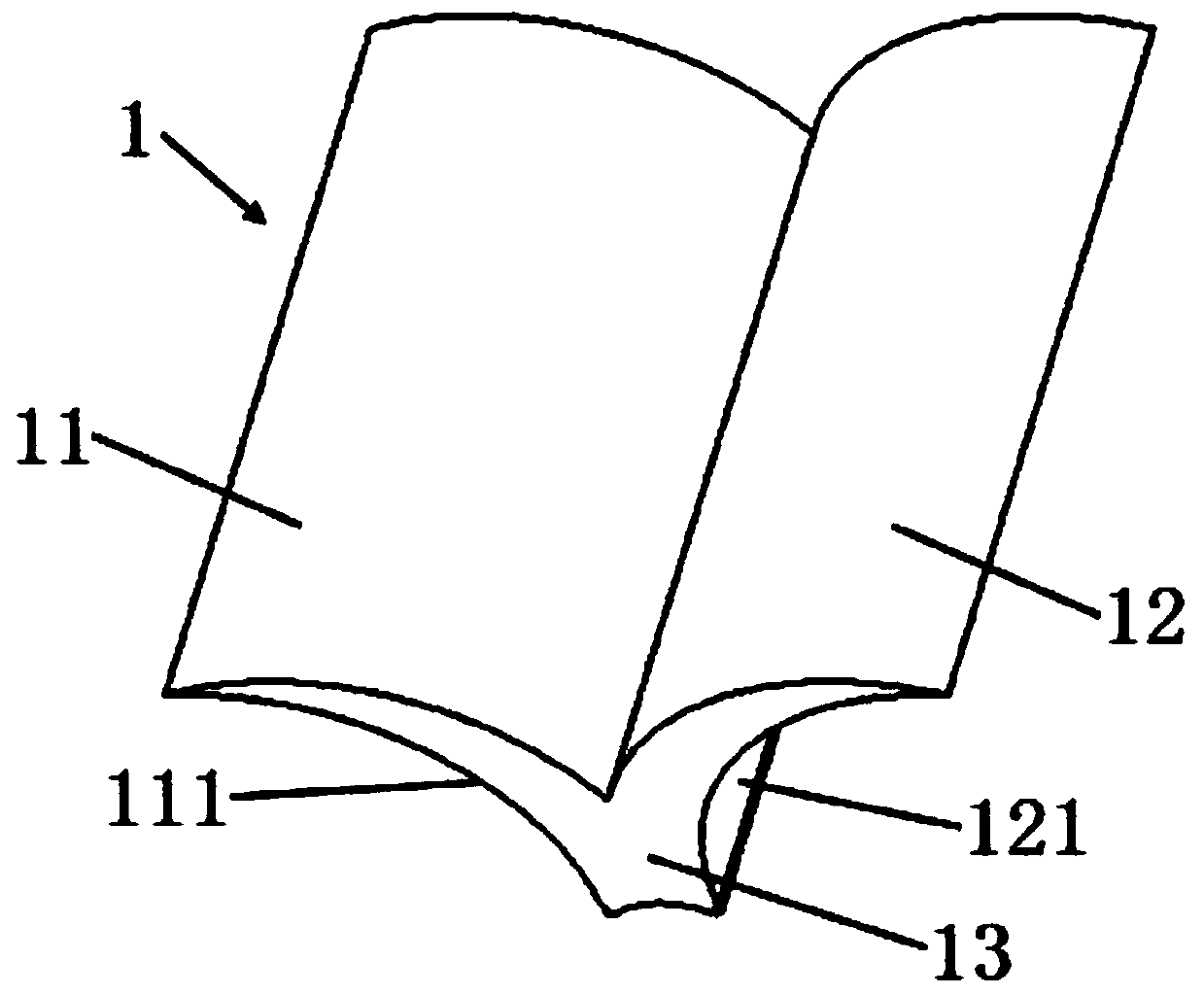

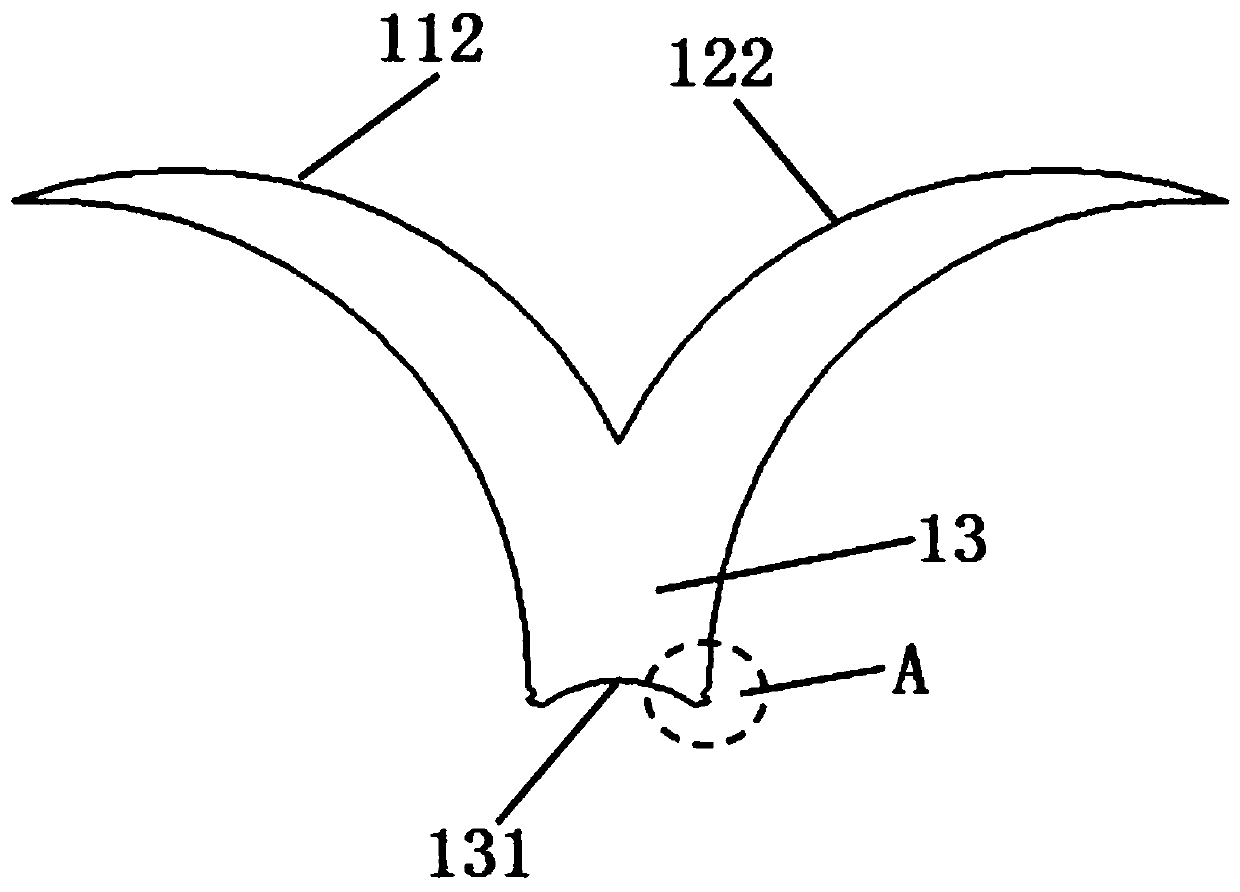

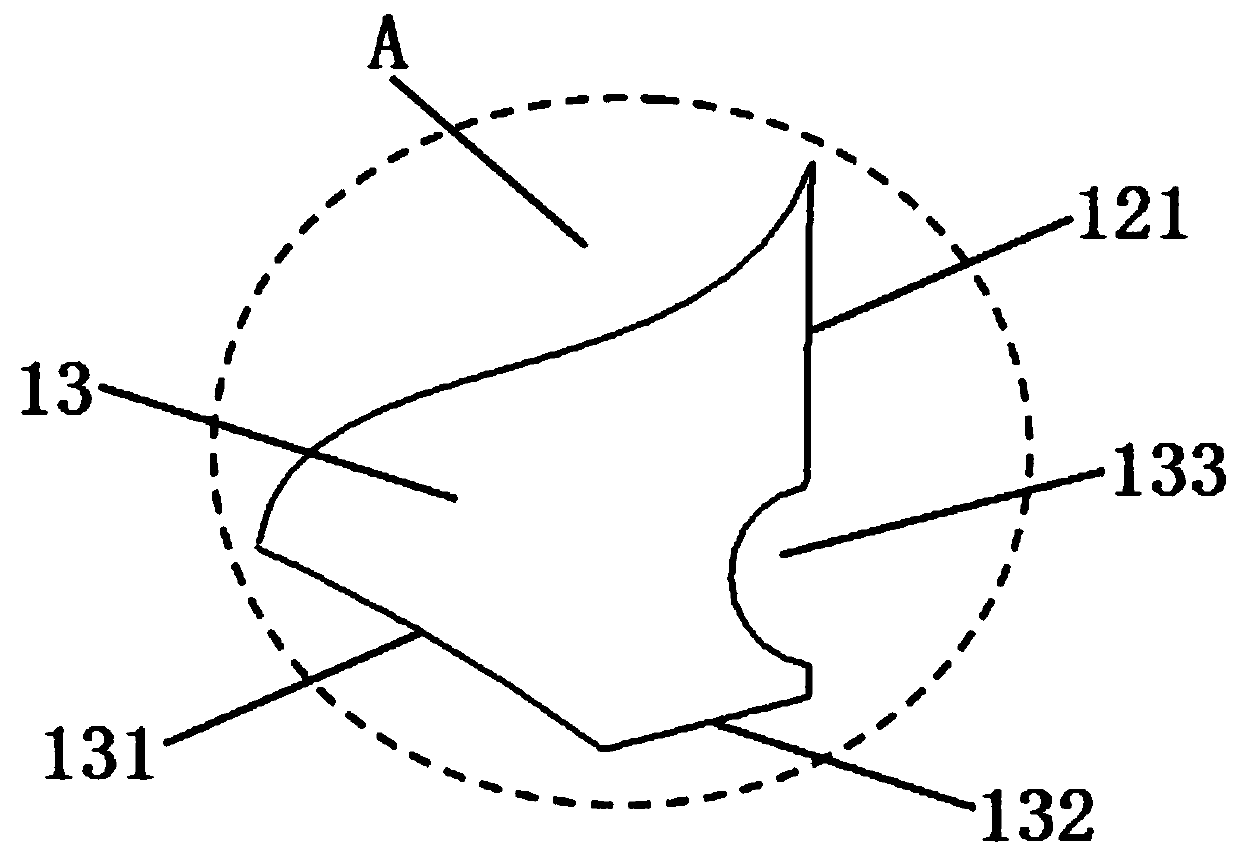

Light preform structure and mold thereof

The invention discloses a light preform structure. The light preform structure comprises a preform with an opening. The cross section, along the center axis of the preform, of the preform is a datum plane. The outer side edge of the datum plane comprises an outer bottleneck segment, an outer bottle body segment and an outer bottle bottom segment which are all sequentially connected, and correspondingly, the inner side edge of the datum plane comprises an inner bottleneck segment, an inner bottle body segment and an inner bottle bottom segment which are all sequentially connected. The outer bottle bottom segment is a structural line or is formed by sequentially connecting multiple structural lines. The inner bottle bottom segment is a structural line or is formed by sequentially connectingmultiple structural lines. Each structural line comprises a straight line and / or a curved line. The distance between the inner bottle bottom segment and the outer bottle bottom segment is gradually increased in the direction from the bottom of the preform to the opening of the preform. After a bottle is blown through the light preform structure, the bottle bottom segment is correspondingly light,production is easy, the flowing speed is higher during injection molding, the shearing stress is small, the crystallization rate is low, and the practicality is high.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

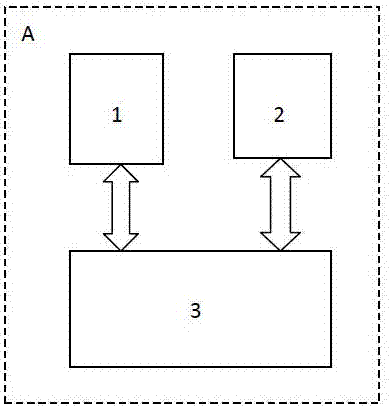

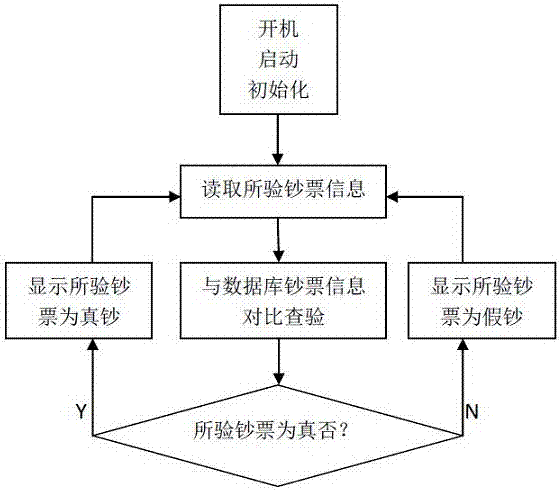

Currency examination method

InactiveCN107067534AReduce storageBanknote verification method is simpleComplete banking machinesPaper-money testing devicesAcousto-opticsComputer science

The invention introduces a currency examination method. The currency examination method includes the steps: utilizing the existing resources and parts of a mobile phone or a flat computer, performing comparison and examination on the counterfeit currency in a currency information data base after reading the information of the examined currency to obtain the real and counterfeit information of the examined currency, and then displaying the real and counterfeit information or performing an acousto-optic alarming. The currency examination method has the advantages of being simple in construction, being easy to implement, being lower in cost, being lighter in weight of product, and being convenient to carry.

Owner:CHENGDU AOCTER TECH CO LTD

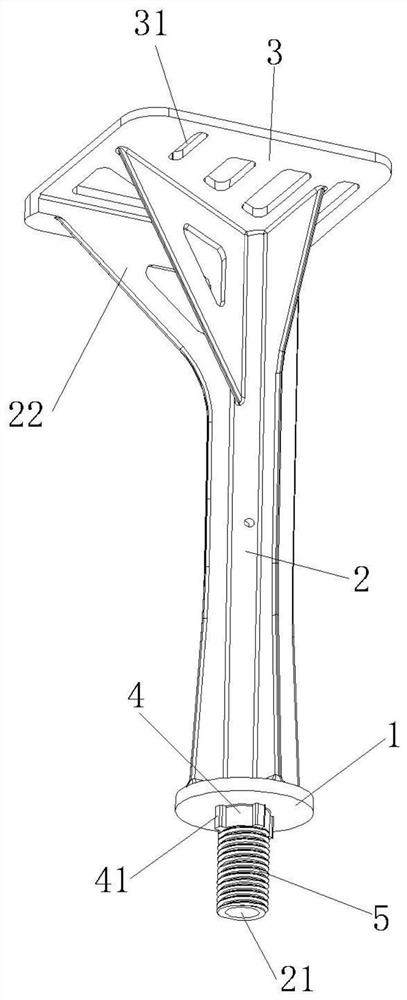

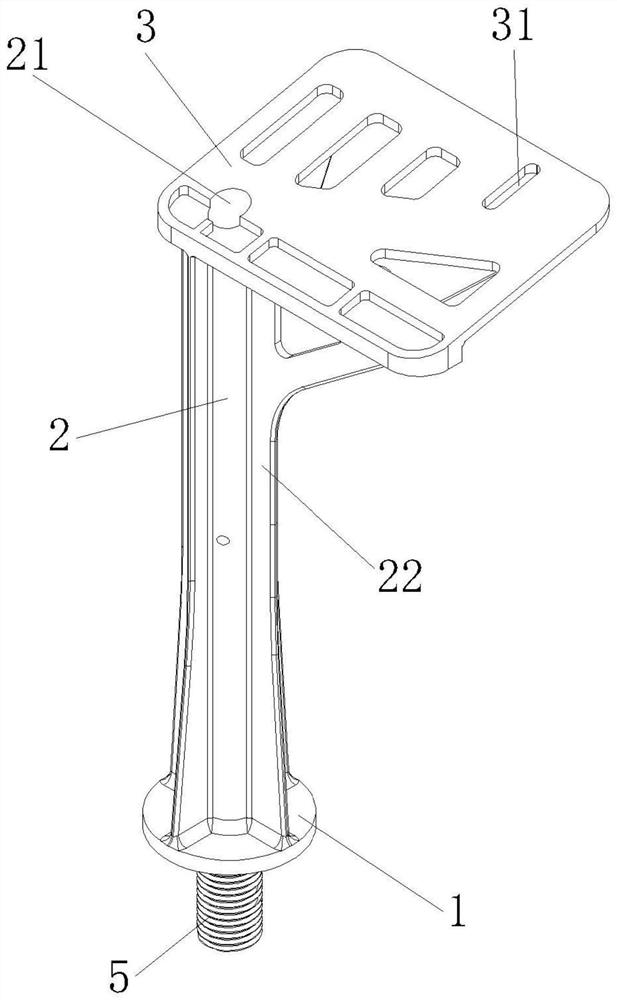

Photovoltaic panel mounting bracket for water surface floating body power station and manufacturing method thereof

PendingCN111987976APrevent rotationLow costPhotovoltaic supportsPhotovoltaic energy generationPower stationStructural engineering

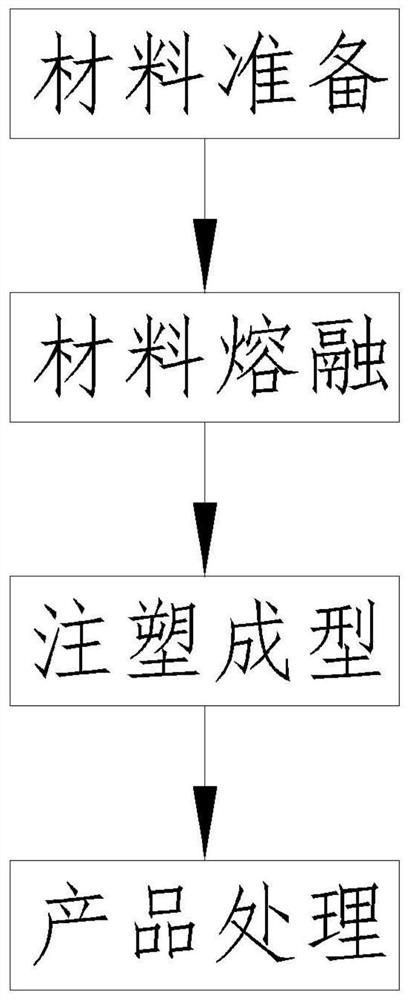

The invention discloses a photovoltaic panel mounting bracket for a water surface floating body power station and a manufacturing method thereof. The mounting bracket comprises an integrally-formed support body. The support body comprises a first supporting plate, a stand column and a second supporting plate. A first angle is formed between the first supporting plate and the second supporting plate. A stand column is fixedly connected between the first supporting plate and the second supporting plate, a connecting column is fixedly connected to the bottom of the first supporting plate, a threaded column is fixedly connected to the lower end of the connecting column, a thread is formed in the outer wall of the threaded column, and an installation long-strip-shaped hole is formed in the second supporting plate. The method comprises the following steps: step 1, preparing materials; step 2, melting the materials; step 3, performing injection molding; step 4, performing product treatment. The mounting bracket is formed by PE plastic through injection molding, and is low in cost, high in strength, high in manufacturing efficiency and not prone to aging.

Owner:苏州吴江区浩强管理技术咨询合伙企业(有限合伙)

Comprehensive utilization method for recycling manganous carbonate slag

ActiveCN101543829BSave resourcesHigh recycling valueSolid waste managementSolid waste disposalLand resourcesSlag

The invention relates to a comprehensive utilization method for recycling manganous carbonate slag. The method comprises the following steps: (1) screen separation; (2) dilution and agitation; (3) integrated separation; (4) dehydrating and drying; (5) package; and (6) repreparation of cement retarder or mixing and pressing of walling material or repreparation of slag cement. The method has the advantages that about 20 percent of manganous carbonate concentrate, iron and other heavy metals in the manganous carbonate slag reaching mine-entering grade (content of manganese metal is 17 percent) are recycled by using integrated separation technology, and the secondary tailing part remained after the integrated separation replaces plaster to be the cement retarder, or the walling material, or the slag cement; and the method can fundamentally solve the problem of the pollution on the environment caused by the manganous carbonate slag, make full and reasonable use of resources in the manganouscarbonate slag, save land resource, improve the comprehensive utilization value of the manganous carbonate slag and completely realize zero discharge of the manganous carbonate slag.

Owner:湖北长阳宏荣环保科技有限公司

Refrigerant and refrigeration equipment using same

ActiveCN102115664BSmooth meltingAvoid destructionDomestic cooling apparatusLighting and heating apparatusInsulation layerGranularity

The invention relates to a preparation method of a refrigerant and a freezer filled with the refrigerant. The lowering speed of the refrigeration temperature is controlled through the regulation of salt granularity in the components of ice and salt in the refrigerant. The invention also provides the freezer filled with the refrigerant. The freezer comprises a box body provided with a heat insulation layer and a heat insulation cover, wherein, the heat insulation layer is further provided with a freezing interlayer; and the freezing interlayer is used for being filled with the refrigerant. Thesurfaces of blocks of ice are covered with salt particles to facilitate steady melting of the ice and the salt, and different refrigeration effects are achieved according to different mesh numbers ofthe salt particles, thereby solving the problem that the nutrients of food are destroyed by over-quick and unsmooth ice-salt refrigeration temperature change; and the product is light in weight, is easy to popularize in the society, and is simple and practical.

Owner:江苏博悦物联网技术有限公司

Crisp bean curd balls and preparation method thereof

PendingCN114468273AUndamagedHeat-sensitive substances stand outFood preservationFood ingredientsBiotechnologyFood additive

The invention belongs to the field of food processing technical equipment, and particularly discloses crisp bean curd balls and a making method thereof.The crisp bean curd balls comprise bean curd ball wrappers and stuffing, the bean curd ball wrappers comprise 10-20 parts of defatted soybean protein powder, 8-25 parts of soybean oil, 2-5 parts of honey, 6-10 parts of egg white, 0.05-0.5 part of transglutaminase, 5-8 parts of starch and 0.5-1.5 parts of food additives; the stuffing can be meat or vegetable, and the stuffing is fried, so that the problems that the traditional bean curd is damaged, is easy to rot and is not easy to carry and popularize can be solved.

Owner:闫润明

Cable with herringbone members and photoelectric composite cable

InactiveCN111180127AAvoid punctureLess componentsCommunication cablesInsulated cablesElectric cablesMaterials science

Owner:常熟虞星光电科技有限公司

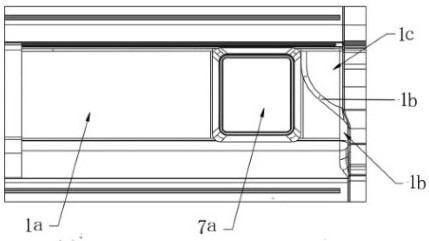

Manufacturing method of driver fence rear enclosure and manufacturing method of driver fence driver door

InactiveCN112536966ASimple structureImprove consistencyPedestrian/occupant safety arrangementStructural engineeringUltimate tensile strength

The invention discloses a manufacturing method of a driver fence rear enclosure and a manufacturing method of a driver fence driver door. The manufacturing method of the rear enclosure comprises the steps of 1) preparing a mold, and specifically, manufacturing a foaming mold meeting requirements according to the shape and structure requirements of the rear enclosure; 2) selecting a surface material and placing the surface material in a lower mold body, and adsorbing or suspending and tensioning an inner surface base material on the surface of an upper mold body; 3) laying a reinforcing material layer zone 1b in the lower mold body of the mold, so that the reinforcing material layer zone 1b is large in density and high in strength; 4) injecting a polyurethane foaming material through high-pressure foaming, assembling the upper mold body and the lower mold body, carrying out maintaining pressure and curing, and completing integral forming of the rear fence; and 5) taking out of a productafter the product is cured, and carrying out edge cutting and trimming. For the manufacturing method of the driver door, the manufacturing method is the same, and a different mold is used. The overall structure is simple, the assembly efficiency is high, the final assembly time is 67% of that of a split structure product, the number of assembly parts is small, no gap exists, the strength is high,stability is achieved, no abnormal sound exists, the inner surface and the outer surface are formed in place at a time, and the cost is low.

Owner:湖南亚太实业有限公司

Comprehensive utilization method of manganese oxide slag recovery

ActiveCN101543830BHigh recycling valueAchieving zero emissionsSolid waste managementSolid waste disposalLand resourcesSlag

The invention relates to a comprehensive utilization method for recycling manganese oxide slag. The method comprises the following steps: (1) screen separation; (2) dilution and agitation; (3) integrated separation; (4) dehydrating and drying; (5) package; and (6) repreparation of cement retarder or mixing and pressing of walling material or repreparation of slag cement. The method has the advantages that about 30 percent of manganese oxide concentrate (content of manganese metal is over 30 percent), iron and other heavy metals in the manganese oxide slag are recycled by using integrated separation technology, and the secondary tailing part remained after the integrated separation replaces plaster to be the cement retarder, or the walling material, or the slag cement; and the method can fundamentally solve the problem of the pollution on the environment caused by the manganese oxide slag, make full and reasonable use of the resources in the manganese oxide slag, save land resource, improve the comprehensive utilization value of the manganese oxide slag and realize zero discharge of the manganese oxide slag.

Owner:广西润华环保科技有限公司

Preserved high mountain yellow peaches and preparation method thereof

InactiveCN113397027AImprove resource utilizationImprove securityConfectionerySweetmeatsVitamin CSucrose

The invention relates to the technical field of preserved fruit production, in particular to preserved high mountain yellow peaches and a preparation method thereof. The preserved high mountain yellow peaches comprise the following ingredients: high mountain yellow peaches, white granulated sugar, honey, water, sucralose, pectin, edible flowers, vitamin C and table salt. The preparation method of the preserved high mountain yellow peaches comprises the following steps: S1, material selection: selecting high mountain yellow peaches of which the maturity is 80-90% and the sugar degree is greater than 15 degrees; S2, feeding, conveying, cleaning, then mechanically cutting into slices, and removing kernels; S3, soaking the high-mountain yellow peach slices obtained in step S2 in saline water for color protection; S4, preparing a sugar solution, and carrying out vacuum sugar permeation treatment on the high mountain yellow peach slices obtained in S3; S5, performing heat pump closed dehumidification drying on the high mountain yellow peach slices subjected to sugar permeation in step S4; and S6, cooling the dried high mountain yellow peach slices obtained in step S5, and then packaging and detecting the cooled high mountain yellow peach slices. Mechanical operation is achieved, the sugar permeation time is short, and the preserved high mountain yellow peaches are natural in color and luster, strong in taste layering sense, and capable of promoting salivation, promoting appetite, invigorating spleen and promoting digestion.

Owner:GUANGDONG IND TECHN COLLEGE

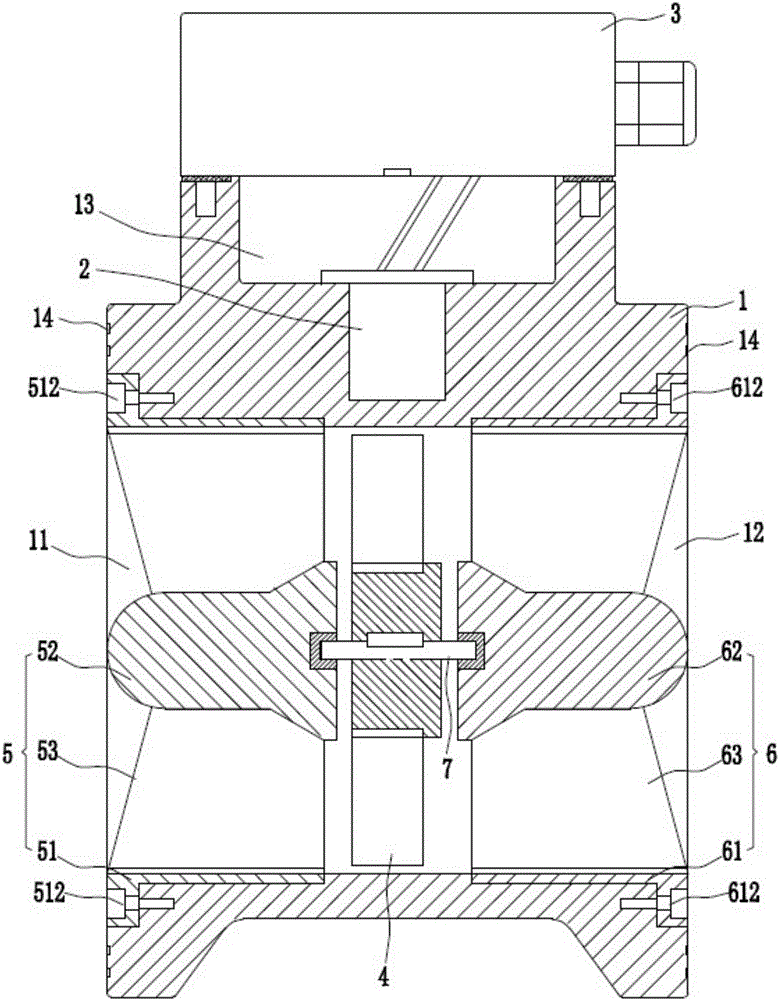

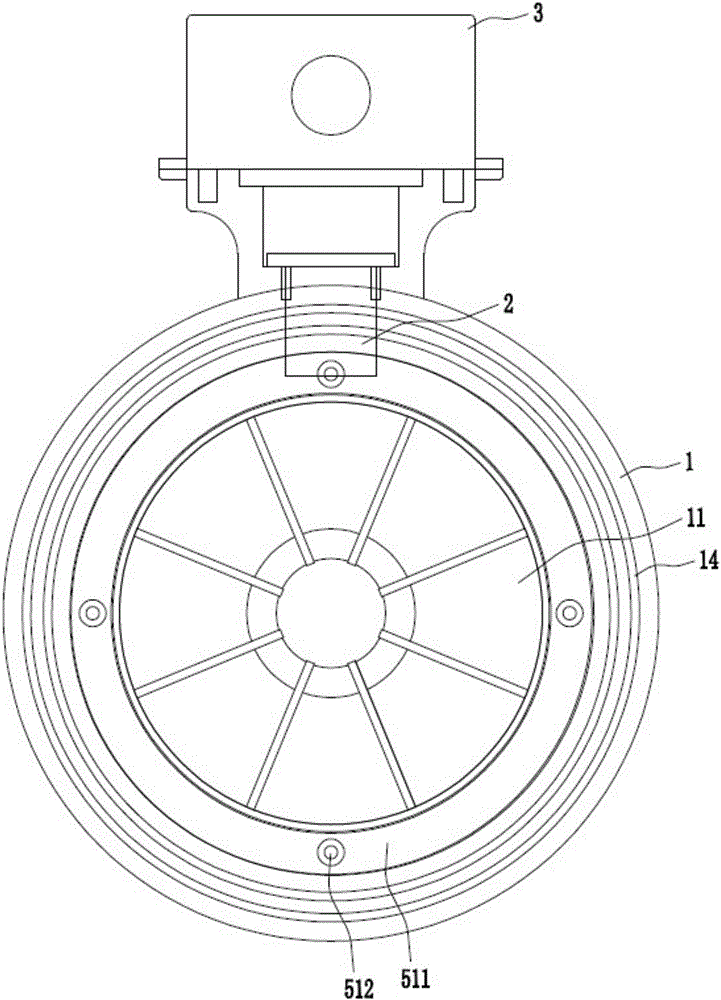

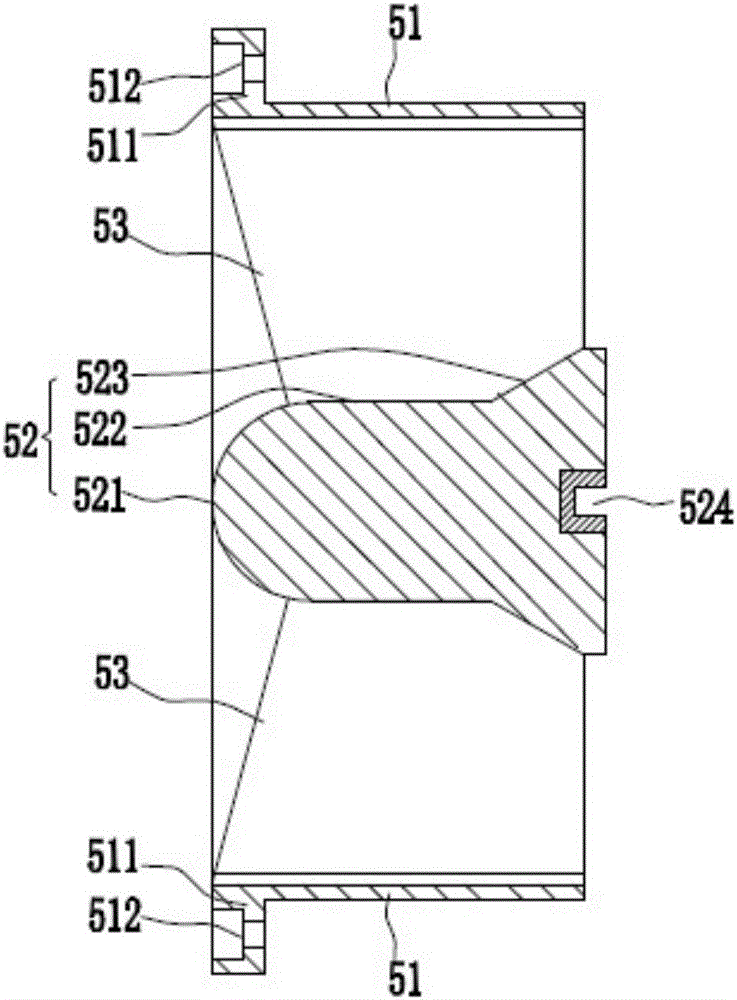

Light high-strength turbine flowmeter

InactiveCN105698876AReasonable structural designGuaranteed measurement effectVolume/mass flow by mechanical effectsEngineeringHigh intensity

The invention relates to the technical field of metering equipment, in particular to a light high-strength turbine flowmeter. The light high-strength turbine flowmeter comprises an outer shell, a turbine rotationally arranged in the outer shell, a front fluid director and a rear fluid director. The outer shell is provided with a fluid inlet, a fluid outlet and a measurement connector, wherein a flow measuring device is installed at the measurement connector. The turbine transmits rotating force to the flow measuring device. The front fluid director is arranged at the front end inside the outer shell and used for guiding fluid onto the turbine to rotate the turbine. The rear fluid director is arranged at the rear end inside the outer shell and used for guiding the fluid to be discharged out of the fluid outlet of the outer shell. The outer shell, the front fluid director and the rear fluid director are all made of nylon materials. The light high-strength turbine flowmeter is reasonable in overall structure design, capable of effectively reducing product weight, convenient to produce, transport and install and capable of reducing product cost.

Owner:TALENT SCI & TECH CO LTD

A method for large-scale production of relief decorative paintings

InactiveCN103481723BReduce process linksHigh degree of mechanizationDecorative surface effectsSpecial ornamental structuresIndustrial engineeringMolding (decorative)

The invention belongs to the field of decorations, and specifically relates to a method for large-scale production of embossed decorative paintings, which mainly includes (1) material selection, (2) mold making, (3) molding, (4) surface treatment and (5) bonding bottom plate Frame several processes. The method of the invention has the advantages of less process steps, high degree of mechanization, short production cycle, light product weight, high picture quality and the like.

Owner:邓启文

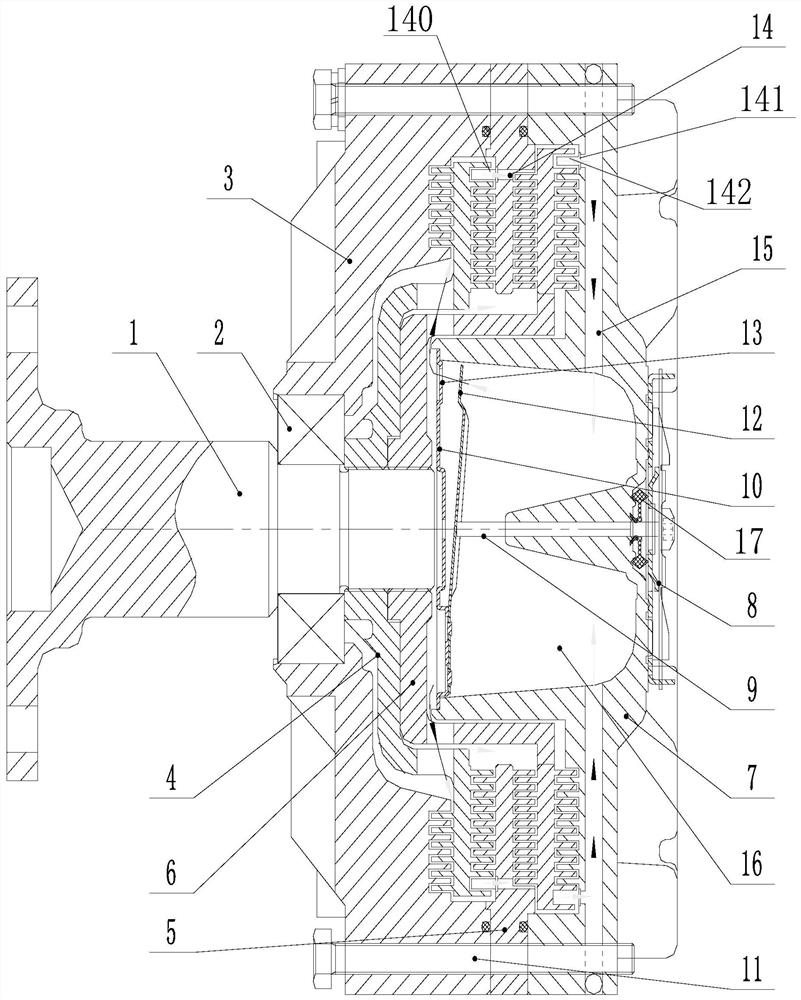

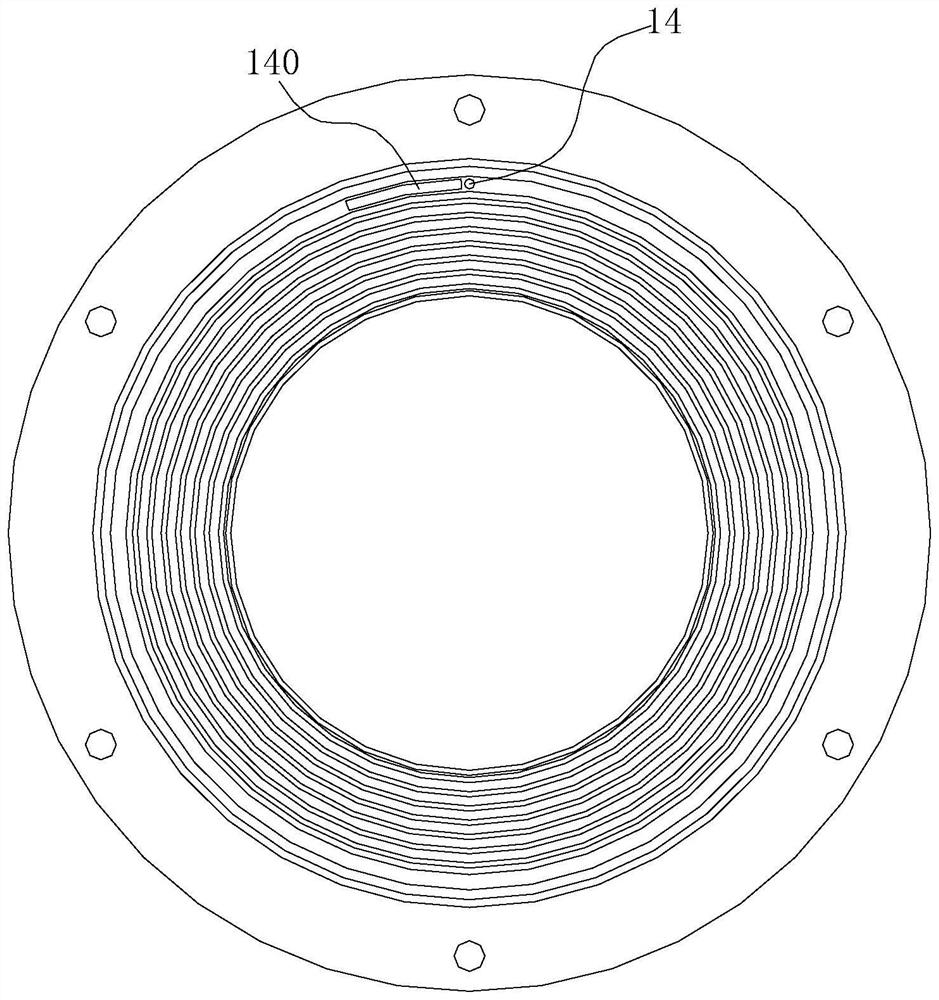

Silicone oil clutch assembly with torque increasing disc

The invention discloses a silicone oil clutch assembly with a torque increasing disc, comprising: a driving assembly, the driving assembly comprising a driving shaft, a first driving plate sleeving the driving shaft, and at least one second driving plate sleeving the driving shaft and arranged adjacent to the first driving plate; a driven assembly, the driven assembly comprises a shell rotationally installed on the driving shaft, a torque increasing disc installed on the end face of the shell, an end cover installed on the other end face of the torque increasing disc, and a driven plate installed on the inner wall of the end cover and provided with at least one oil outlet hole. The valve block is arranged on the driven plate and is matched with the oil outlet hole; and the valve block control unit is arranged on the end cover and is connected with the valve block to control the valve block to open or close the oil outlet hole. The torque of the clutch assembly product can be increased under the condition that the outer diameter of the silicone oil clutch assembly product is not changed.

Owner:SUZHOU RISING AUTO PARTS

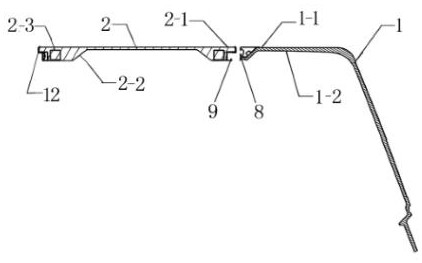

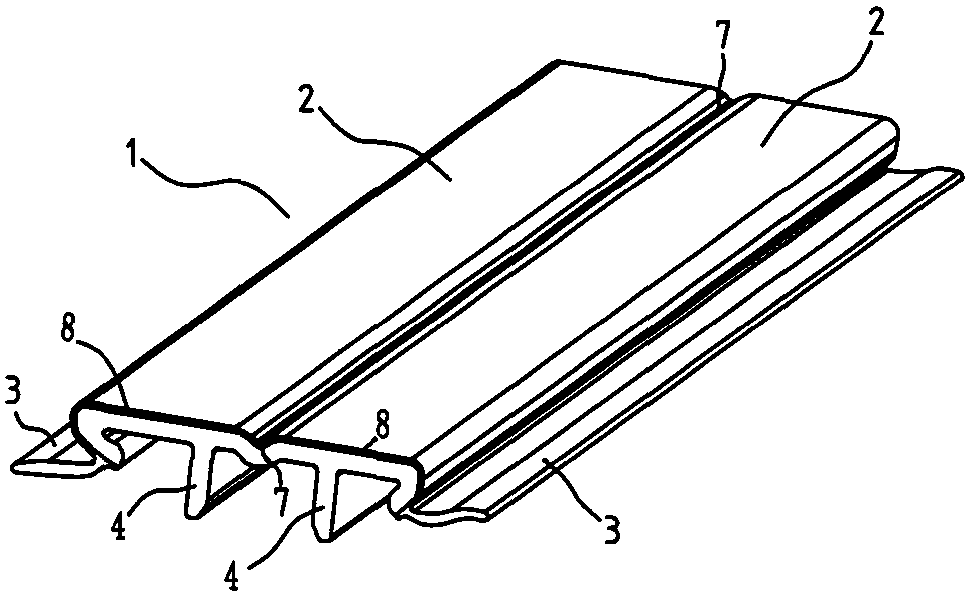

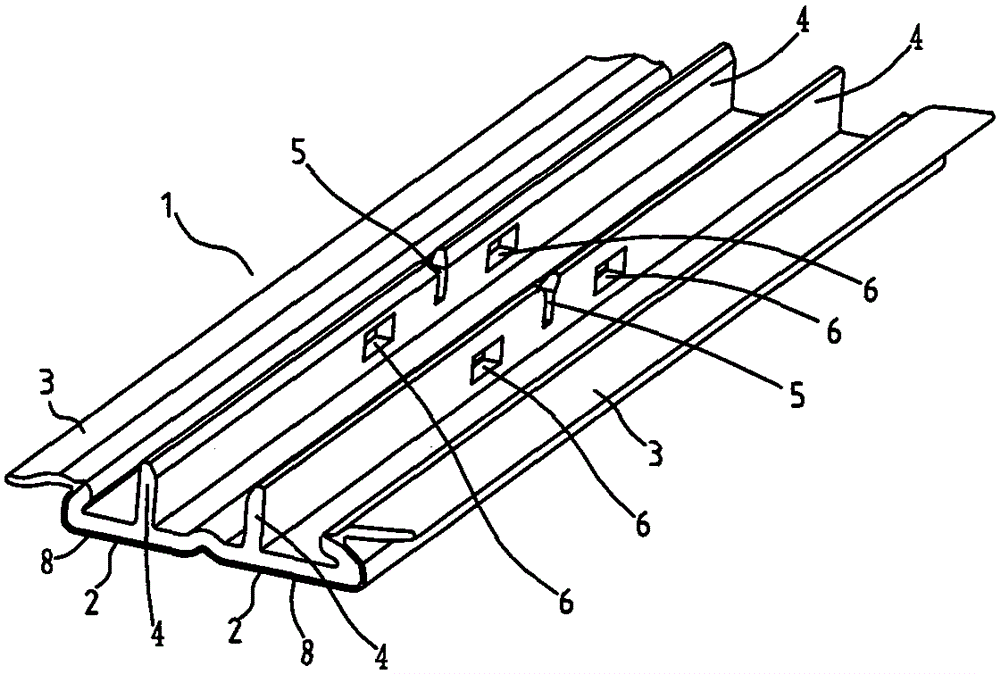

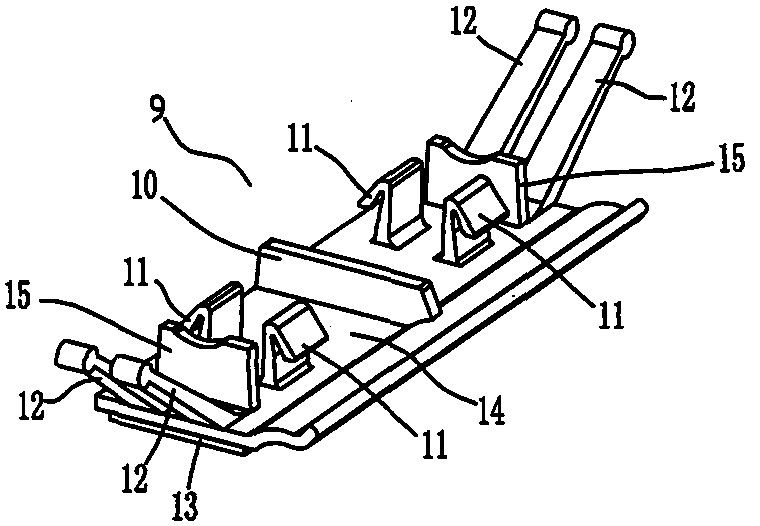

Roof molding and its installation structure

ActiveCN103318104BNot easy to curl and peel offSimple preparation processVehicle componentsFastenerEngineering

The invention provides a car roof decorative strip and an installing structure thereof. The car roof decorative strip comprises a car roof decorative strip body (1) and a fastener (9), wherein the car roof decorative strip body comprises a decorative strip body and decorative strip lip pieces (3) located on two sides and used for adhering to the car roof face during installation. The car roof decorative strip is characterized in that two convex ribs (4) are arranged on the back side of the car roof decorative strip body along the longitudinal direction and provided with a plurality of gaps (5) at the same longitudinal positions at set intervals (a) respectively, and the side faces of the convex ribs located on two sides of each gap are provided with side holes (6) at set interval (b). The fastener comprises a base plate (14), a transverse convex rib (10) is arranged in the middle of the base plate, two sides of the transverse convex rib are provided with four bent buttons (11) for being embedded into the side holes of the car roof decorative strip body, and at least one elastic support foot (12) is arranged at two ends of the base plate respectively and obliquely extends out of the two ends of the base plate upward and outward. A double-sided sticky tape (13) is bonded on the back side of the base plate.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

The manufacturing method of construction materials using waterworks sludge

ActiveCN101528628ANo pollution in the processImprove sound insulation, moisture resistance and heat preservationSolid waste managementCeramic materials productionSludgePhosphoric acid

The present invention discloses a manufacturing method of construction materials using waterworks sludge. The present invention discloses a soundproof construction composition using waterworks sludge and a method for preparing the same. The soundproof construction composition using waterworks sludge manufactured by mixing 22% by weight of a first processed clean water sludge made by firing waterworks sludge for 3-5 hours at 800 DEG C-850 DEG C, with 18% by weight of clay, 36% by weight of terra alba, 14% by weight of agalmatolite, and 10% by weight of dolomite to obtain a body; mixing 31.5% by weight of the body with 2.3% by weight of calcined gypsum, 11.3% by weight of cement, 0.05% by weight of aluminum powder, 0.5% by weight of starch, 0.5% by weight of titanium dioxide to prepare a powdery mixture; and mixing the powdery mixture with 10.8% by weight of phosphoric acid and 43.05% by weight of water.

Owner:赵大衍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com