Breath-freshening pericarp candy and preparation method thereof

A technology of peel candy and chewing gum, which is applied in the field of chewing peel candy and its preparation, can solve the problems of production and sales of chewing gum products without orange peel, and achieve the effect of bright color, fresh fruit aroma, and soft and glutinous taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

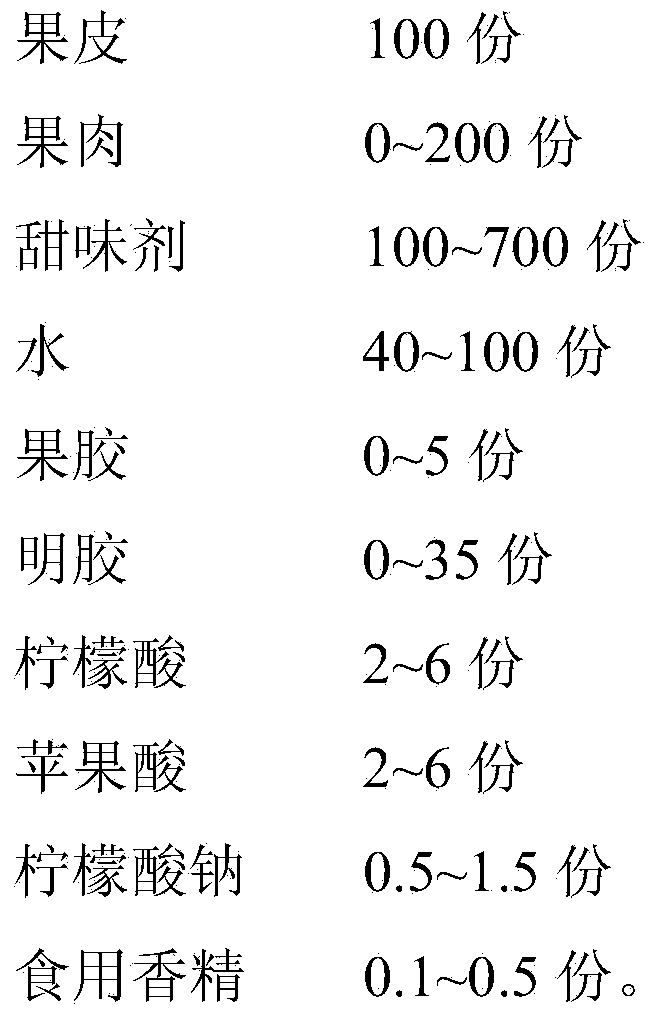

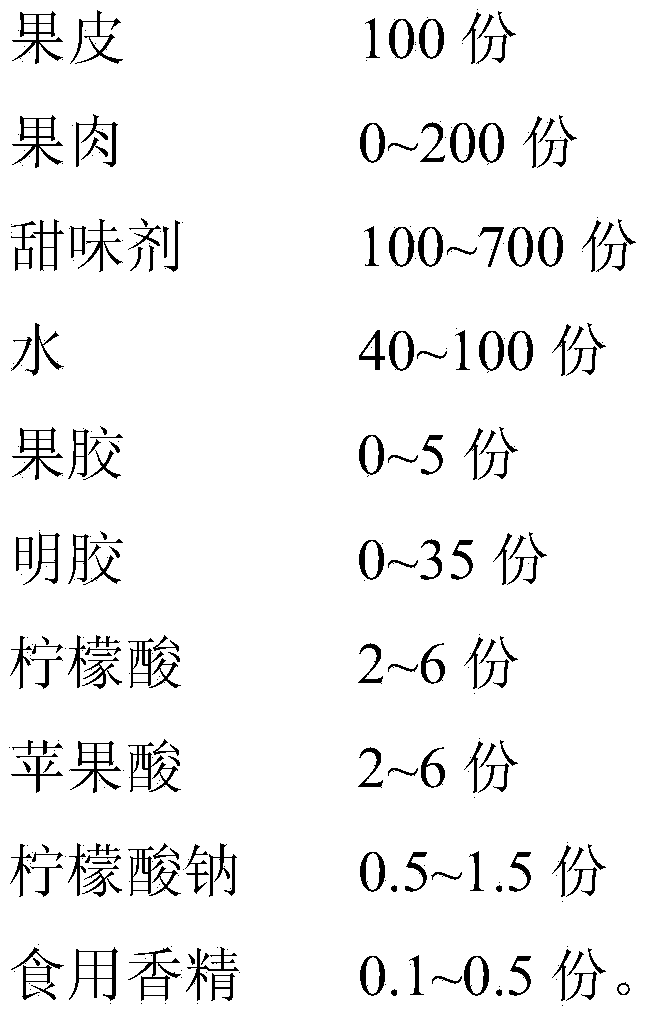

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the preparation of chewing fruit peel candy

[0042] (1) Remove soft, rotten and moldy fruits from navel oranges, and then soak, disinfect, scrub and clean them in sequence.

[0043] (2) On the peeling machine, the oranges are peeled and cut at both ends, and the peel and pulp are separated. The oranges can also be separated into clean pulp + oily skin + sponge white skin + round skin at both ends (also known as money skin) ). According to the needs of the product, cut the peeled peel into small pieces, cubes, and filaments; use a beater to refine the net pulp into pulp, and separate the seeds at the same time. 12kg of gelatin is pre-soaked with 20kg of water for 24h, and is set aside.

[0044] (3) Put 80kg of maltose syrup, 140kg of white granulated sugar, and 120kg of glucose syrup into the cooking pot, boil until slightly boiled, dissolve 1.2kg of pectin with 10kg of water, filter, and pump into the cooking pot. Then stir while cooking, the cooking t...

Embodiment 2

[0052] Embodiment 2: the preparation of chewing fruit peel candy

[0053] (1) Citrus removes soft, rotten and moldy fruits, and then soaks, disinfects, scrubs and cleans in sequence.

[0054] (2) On the peeler, the citrus is peeled and cut at both ends, separating the peel and pulp. According to the needs of the product, cut the peeled peel into filaments; use a beater to refine the net pulp into a pulp, and separate the seeds at the same time. 12kg of gelatin is pre-soaked with 20kg of water for 24h, and is set aside.

[0055] (3) Put 100kg of maltose syrup, 120kg of white granulated sugar, and 130kg of glucose syrup into the cooking pot, boil until slightly boiled, dissolve 1.5kg of pectin with 12kg of water, filter, and pump into the cooking pot. Then while stirring, cook at the same time, the cooking temperature is 110-116°C, the vacuum degree is 0.78-0.8MPa, and after the solid content reaches 65wt%, add 100kg of peel and 60kg of fruit pulp processed in step (2) to cont...

Embodiment 3

[0063] Embodiment 3: the preparation of chewing fruit peel candy

[0064] (1) Grapefruit removes soft, rotten and moldy fruits, and then soaks, disinfects, scrubs and cleans in sequence.

[0065] (2) On the peeling machine, the grapefruit is peeled and cut at both ends, and the peel and pulp are separated. The grapefruit can also be separated into clean pulp + oily skin + sponge white skin according to needs. According to the needs of the product, cut the peeled peel into cubes; use a beater to refine the net pulp into pulp, and separate the seeds at the same time. 12kg of gelatin is pre-soaked with 24kg of water for 24h, and is set aside.

[0066] (3) Put 120kg of maltose syrup, 120kg of white granulated sugar, and 80kg of glucose syrup into the cooking pot, boil until slightly boiling, dissolve 1kg of pectin with 8kg of water, filter, and pump into the cooking pot. Then while stirring, cook at the same time, the cooking temperature is 110-116°C, the vacuum degree is 0.78-0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com