Silicone oil clutch assembly with torque increasing disc

A silicon oil clutch and torsion plate technology, applied in clutches, fluid drive clutches, non-mechanical drive clutches, etc., can solve the problems of reducing the comfort of the engine driver, product weight, and high engine power, and achieve fast installation, light product weight, Installation requires less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will be based on the preferred implementation plan of the present invention.

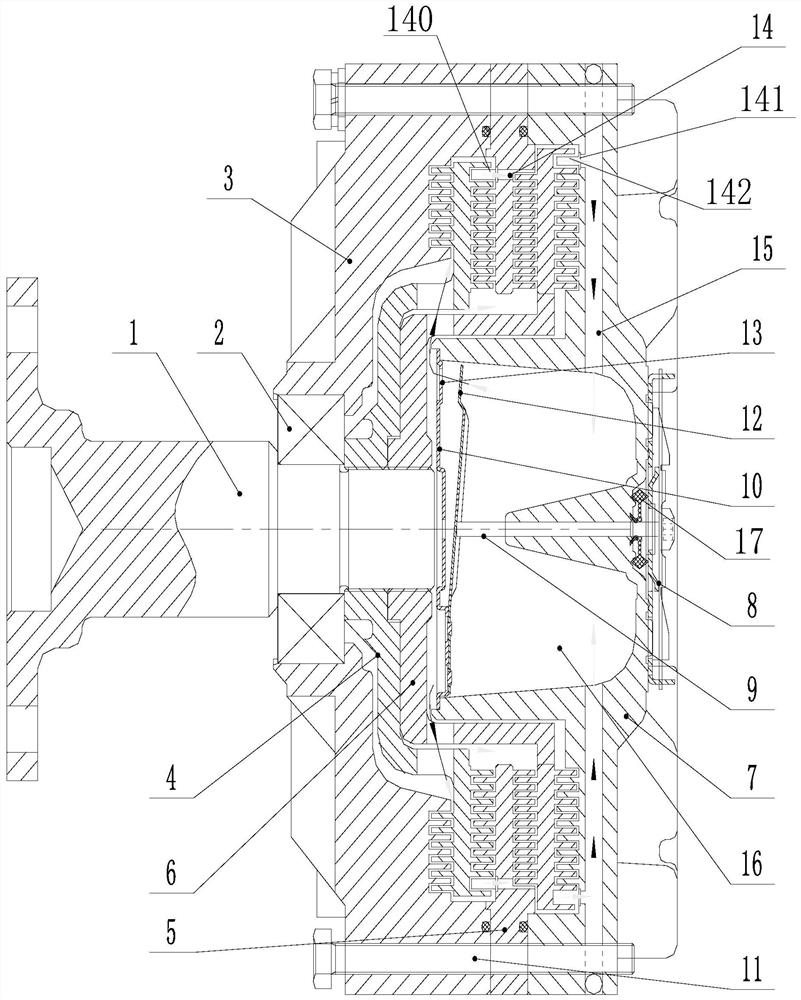

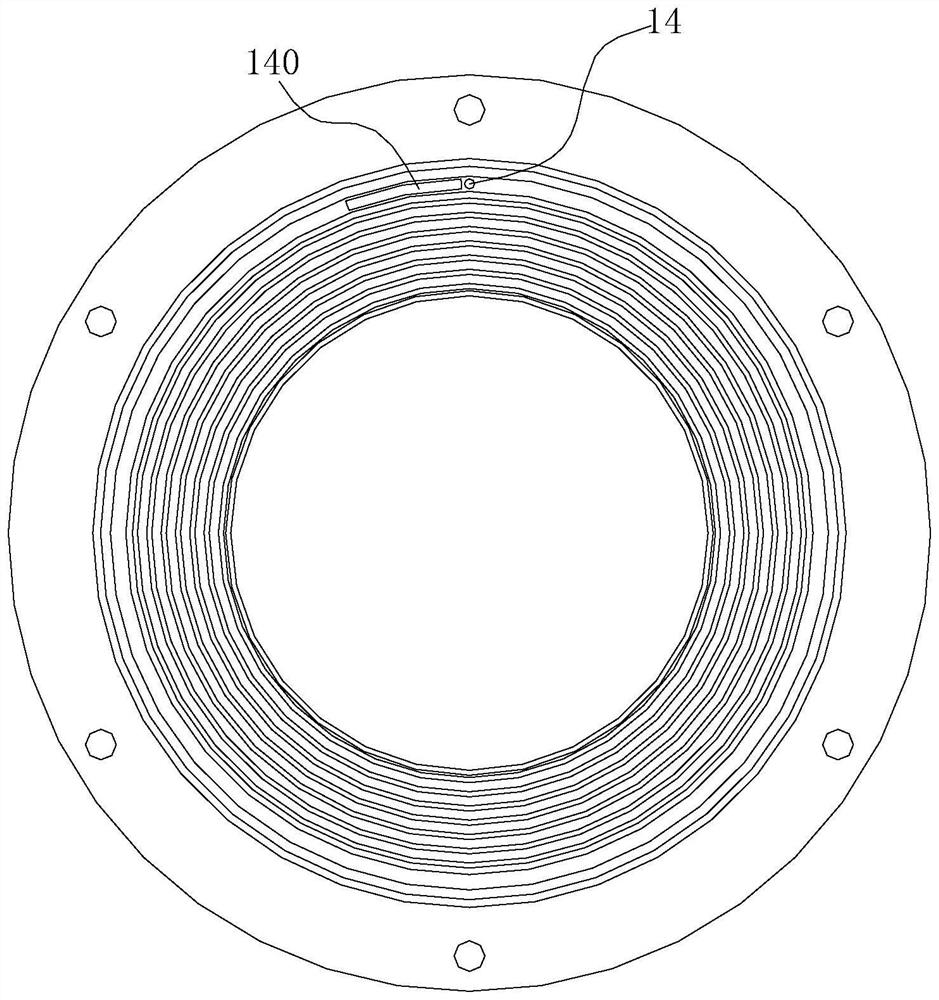

[0022] like figure 1 The silicone clutch assembly with an increased twistter mainly includes the active components and the motion components that cooperate.

[0023] Among them, active components include active axis 1. First active board 4 and second active board 6. The diameter of the active axis 1 is reduced from one end to the other end in the direction of its axis, so that the active shaft 1 forms a multi -step department (which can be used to install other parts such as bearing). The engine rotates. The first active board 4 and the second active board 6 are adjacent to the end with a smaller diameter of the active axis (the end is defined as the external part, and one end of the aforementioned engine is defined as the inner end). The fixed method of a active board 4 and the second active board 6 can be conventional on the fixed method of active axis 1. If conventional tight fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com