Powder hot-melting and bonding technology of automotive carpet

A car carpet and hot-melt bonding technology, which is applied in the field of car carpets, can solve the problems that affect the sound absorption and noise reduction of the carpet, and the weight increase of the carpet, so as to achieve the effect of reducing noise and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The powder hot-melt bonding process of the present invention will be further described in detail through specific examples below.

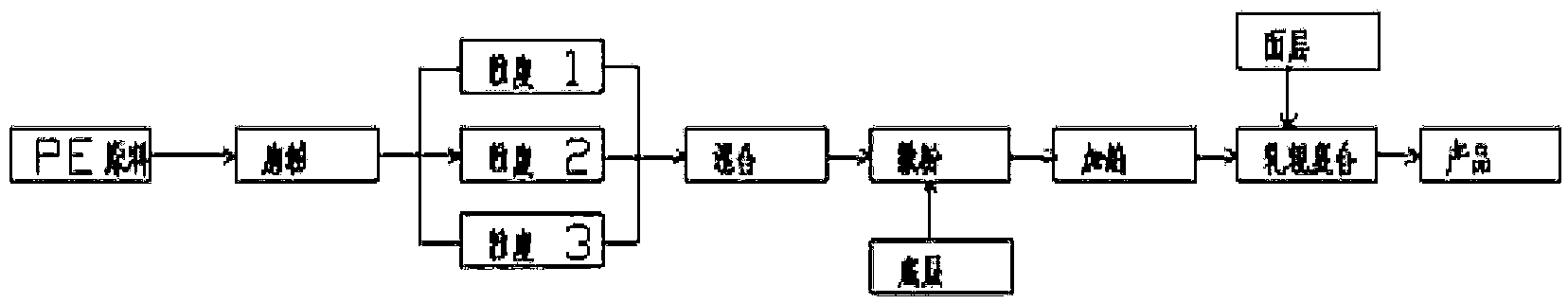

[0019] like figure 1 As shown, the steps of the powder hot-melt bonding process for automobile carpets are:

[0020] a. Grinding the low-melting point polyethylene resin into powders of different particle sizes through a pulverizer,

[0021] b. Divide the powder into four grades according to particle size: 1000μm,

[0022] c. The weight ratio of the powder with a particle size of 1000 μm Mixed in a proportion of 5%-15% by weight,

[0023] d. Sprinkle the mixed powder evenly on the surface to be bonded on the bottom layer through the powder spreader,

[0024] e. Heat the carpet in an oven to soften and melt the powder,

[0025] f. The surface layer and the bottom layer of the carpet are pressed and bonded by rollers.

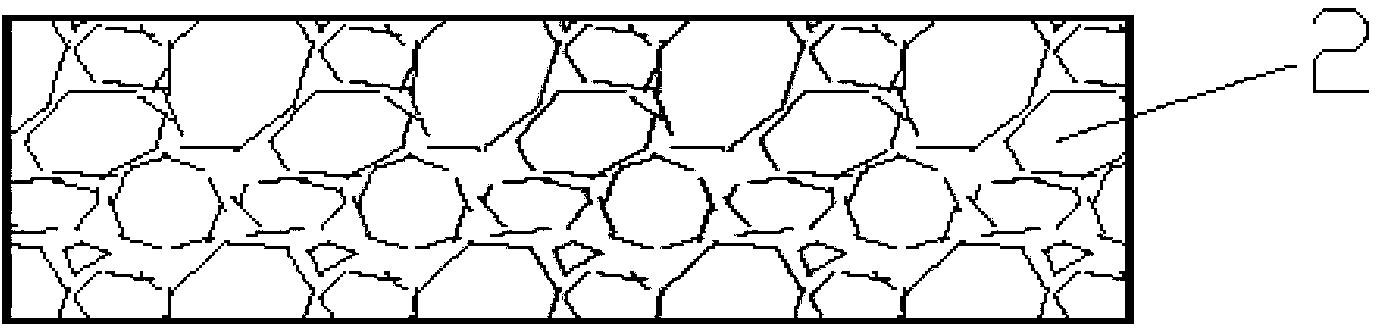

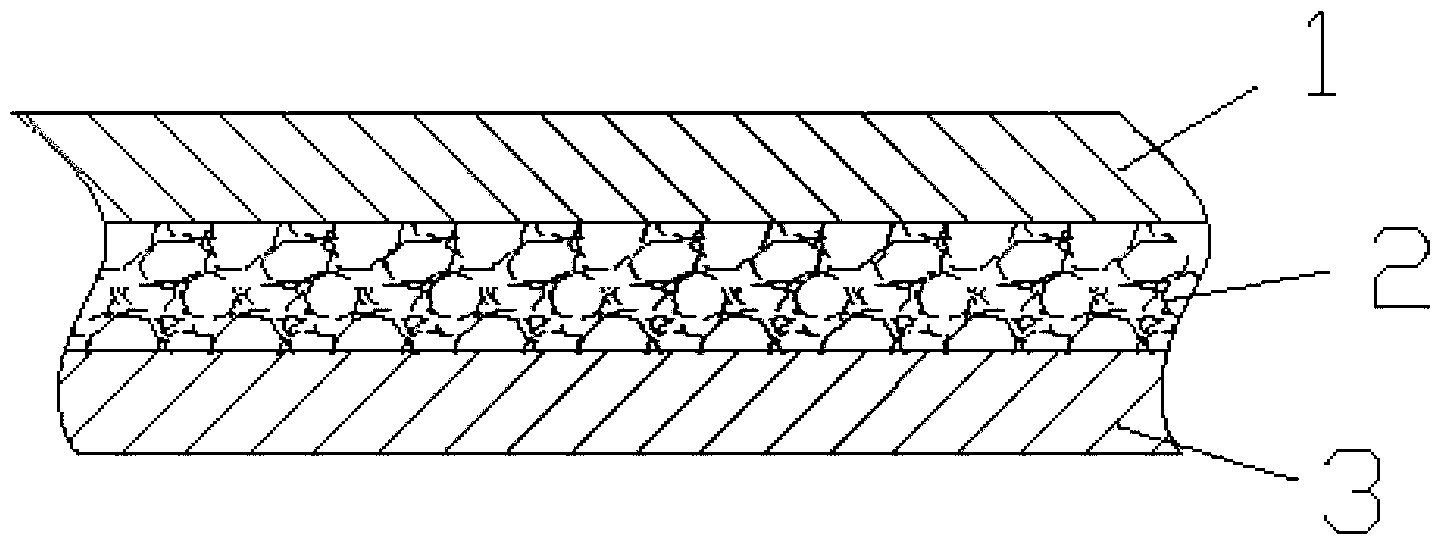

[0026] like figure 2 As shown, powders of different particle sizes and different proportions are evenly sprinkled on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com