Control system capable of quickly responding to automatic level control loop

A technology of automatic level and control loop, applied in the direction of transmission system, electrical components, etc., can solve problems such as poor stability and slow response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

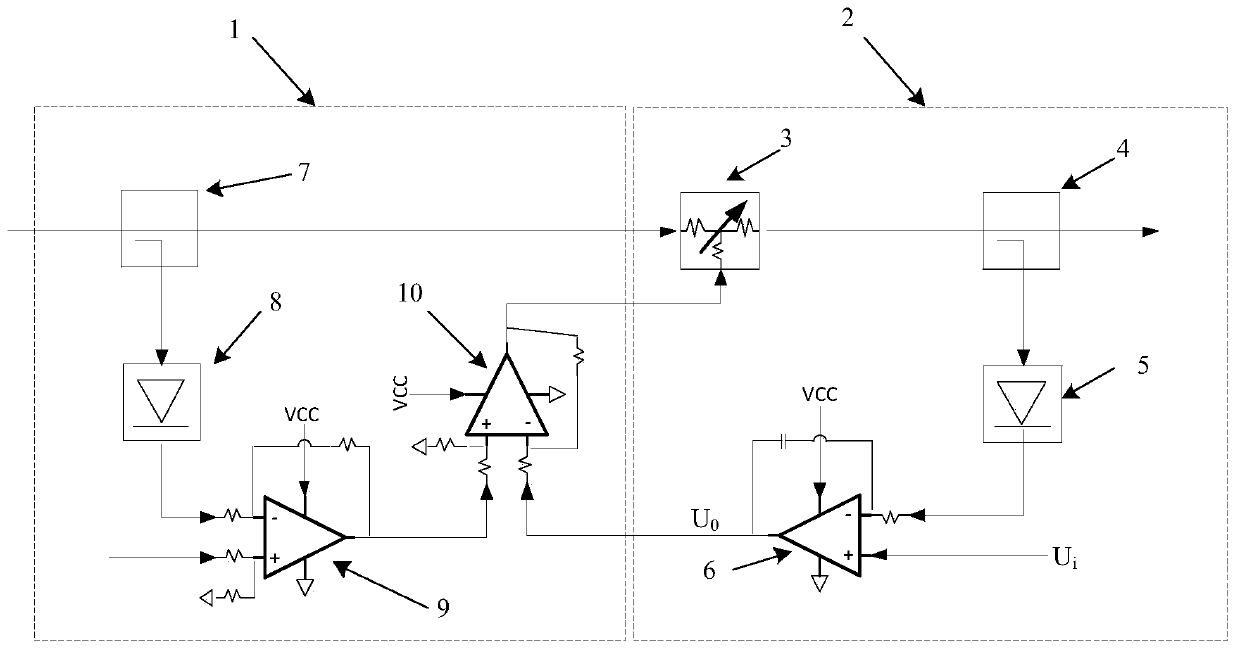

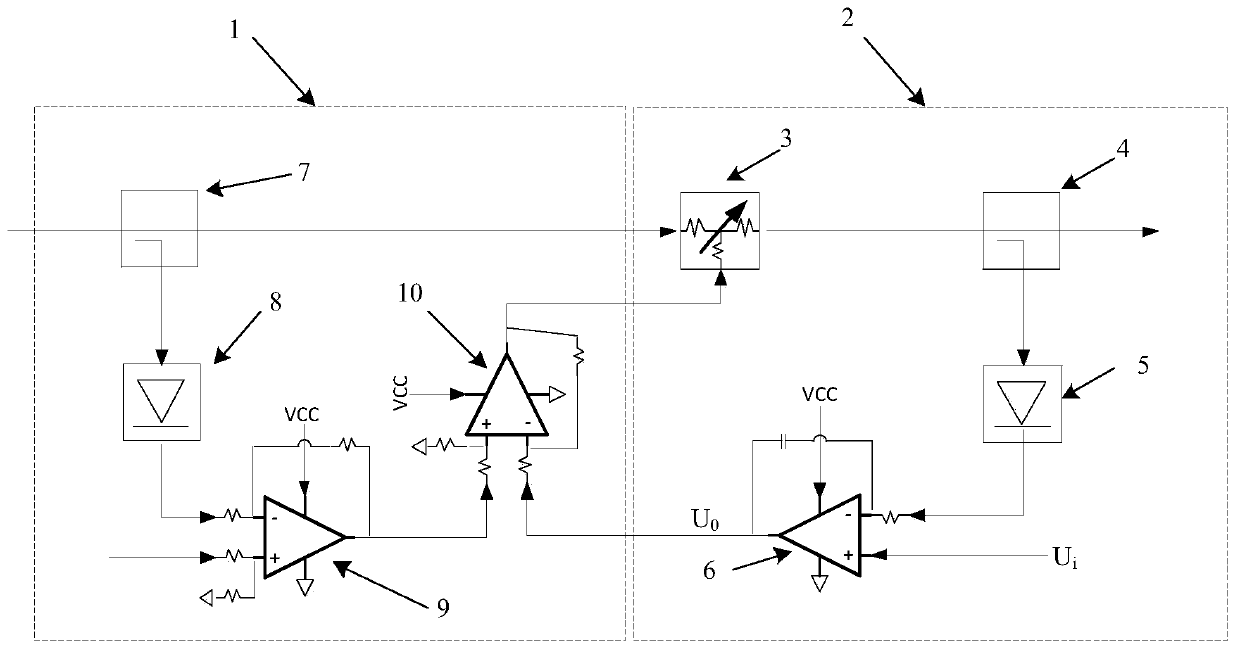

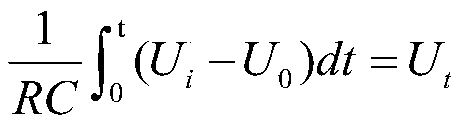

[0024] This embodiment discloses a control system that quickly responds to an automatic level control loop, including: a preset voltage module 1 and an automatic level control ALC loop module 2. The ALC loop module 2 changes when the input signal changes. , The front-end analog attenuator 3 works in the previous control voltage state, the output of the front-end analog attenuator 3 is sampled by the directional coupler 4, after sampling, it is converted into a real-time dynamic voltage by the loop detector 5, and the real-time dynamic voltage is transmitted to the loop Op amp, the loop op amp adjusts its output voltage through proportional calculation or integration, and then provides it to the front-end analog attenuator 3 to form a closed loop. The front-end analog attenuator 3 adjusts its own gain value according to the latest real-time control voltage, and the ALC loop forms The dynamic loop, until the voltage value corresponding to the required output power set at the loop ...

Embodiment 2

[0052] When the dynamic range of the input signal is not large, and the average detection independent of the modulation signal is required, and the peak average of the signal is relatively large, the detector in the ALC loop needs to use an average detector and cooperate with an external capacitor. The averaging detector itself has a slower time response because it contains an averaging part, and the time response time is slower when an external capacitor performs low video filtering on a signal with a high peak-to-average ratio. In order to meet the requirements of fast real-time signal power control, it is necessary to introduce the above-mentioned new preset voltage module 1 to the ALC loop to ensure that the initial attenuation state and final value of the front-end analog attenuator 3 are relatively different before the ALC loop works. small. The preset voltage value needs to be set by the voltage corresponding to the input signal, and the ALC loop completes the ALC closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com