Machine component of an electric machine and method for its manufacture

一种机器、组件的技术,应用在制造这种类型的机器组件,电机。领域,能够解决热退耦等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

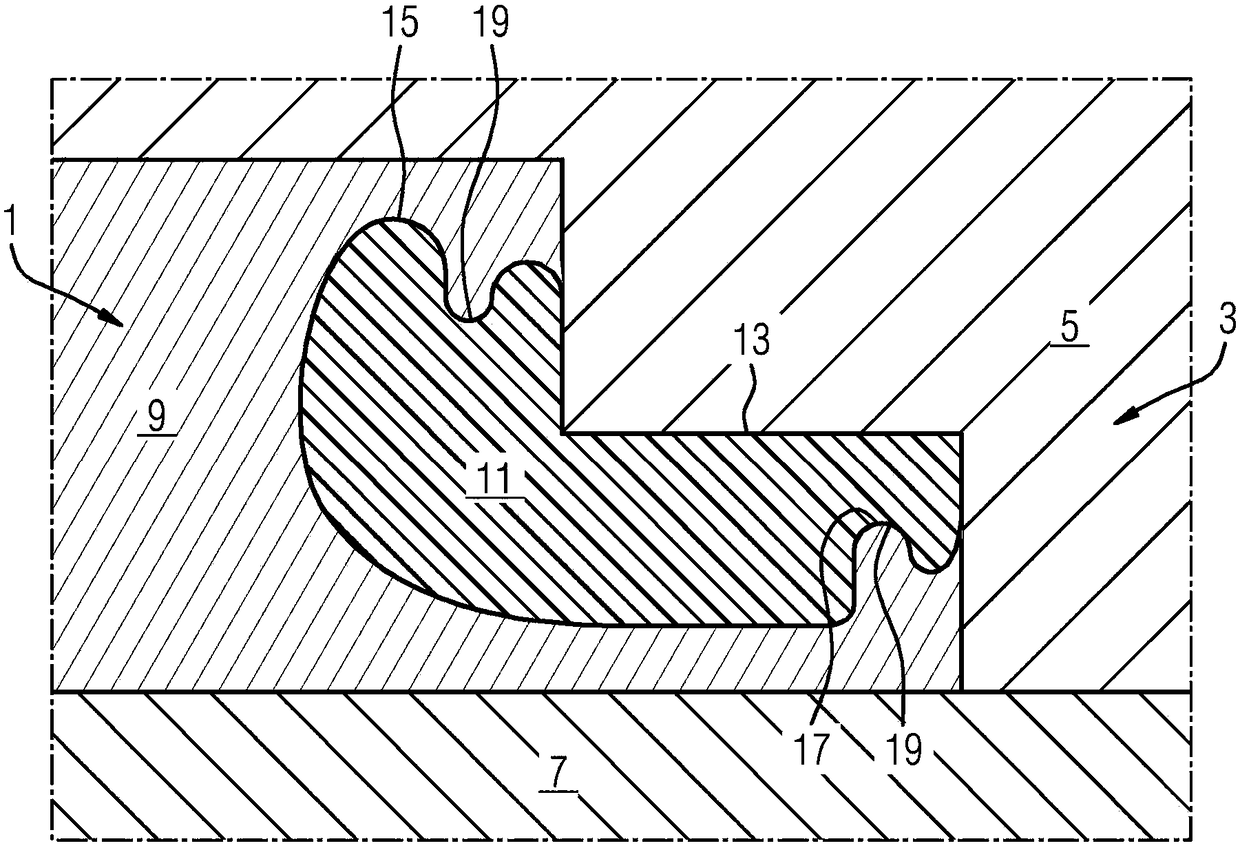

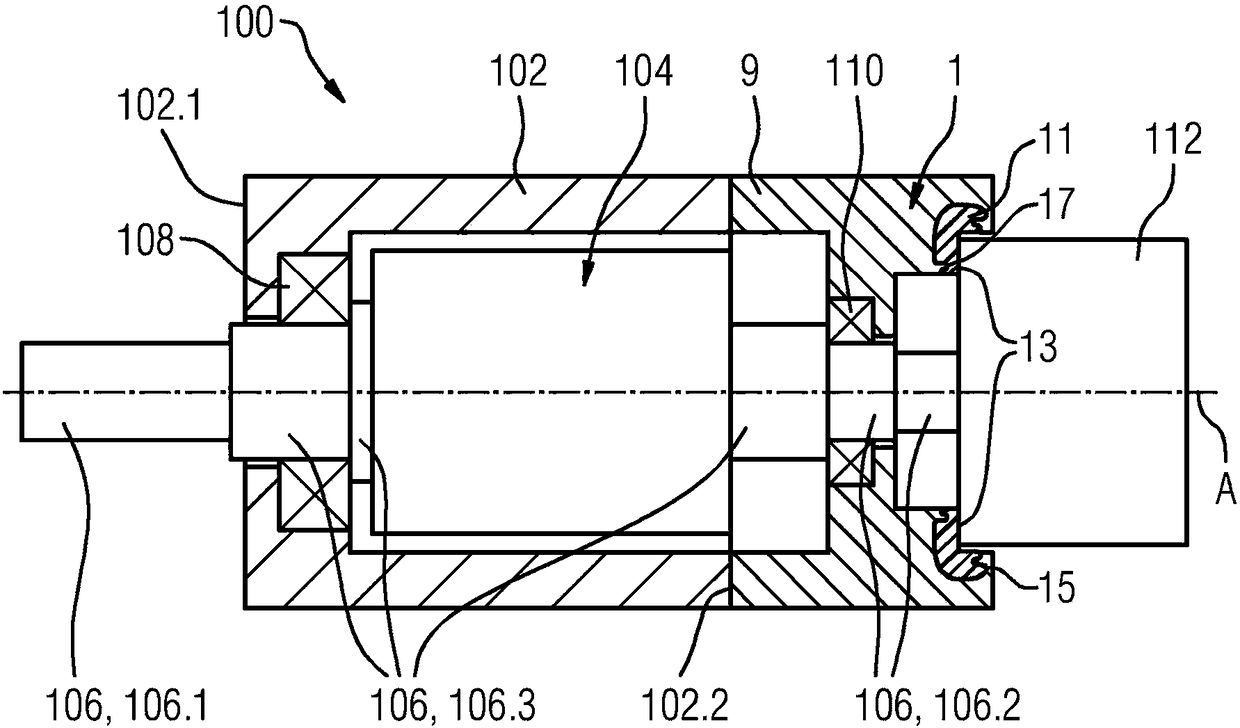

[0029] figure 1 The machine assembly 1 of the electric machine 100 is shown in cross section (see figure 2 ). The machine component 1 is located in an injection mold 3 , which is used to manufacture the machine component 1 and consists of a first mold part 5 and a second mold part 7 . here, in figure 1 Correspondingly only the machine component 1 and the foot membrane parts 5 , 7 are shown in section.

[0030] The machine component 1 comprises a metal base body 9 and a seal 11 made of plastic arranged at the base body 9 for connecting the machine component 1 to a component 112 abutting against it (see figure 2 ) thermal decoupling. The machine component 1 is, for example, a bearing endshield of an electric machine 100 and the seal 11 is designed, for example, as a substantially disk-shaped seal 11 for thermally decoupling the machine component 1 from the generator housing of the measurement value generator abutting against it.

[0031] Preferably, the seal 11 is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com