Vein type multistage curved rib reinforced high-rigidity special-shaped storage tank end socket structure

A high-rigidity, head-sealing technology, applied in aerospace equipment, aerospace aircraft, aerospace equipment, etc., can solve the problems of low improvement efficiency, unfavorable lightweight design, and insignificant structural performance improvement effect, and achieves the The effect of large area bulging deformation, avoiding local bulging deformation, and uniform deformation of the whole structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

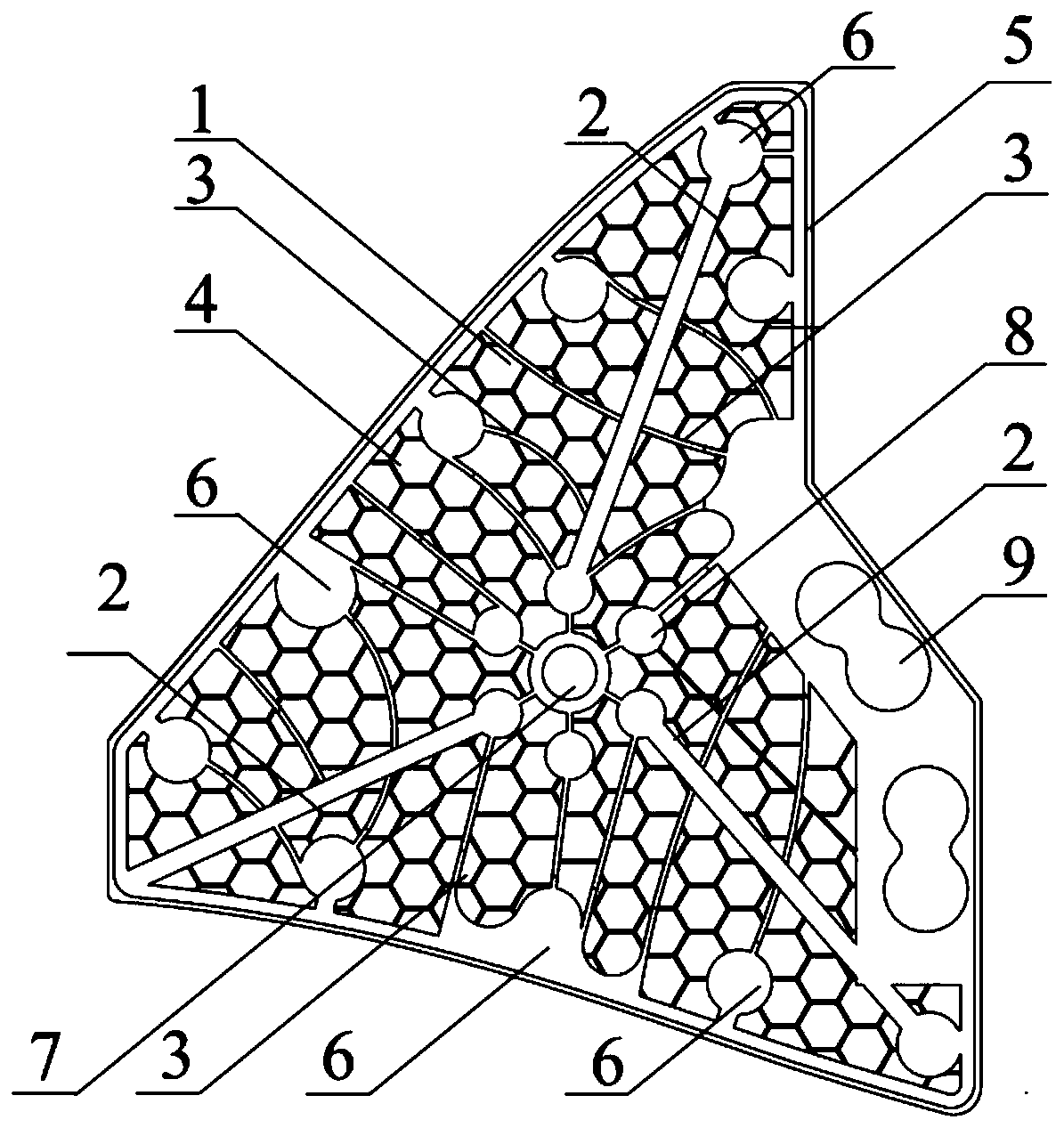

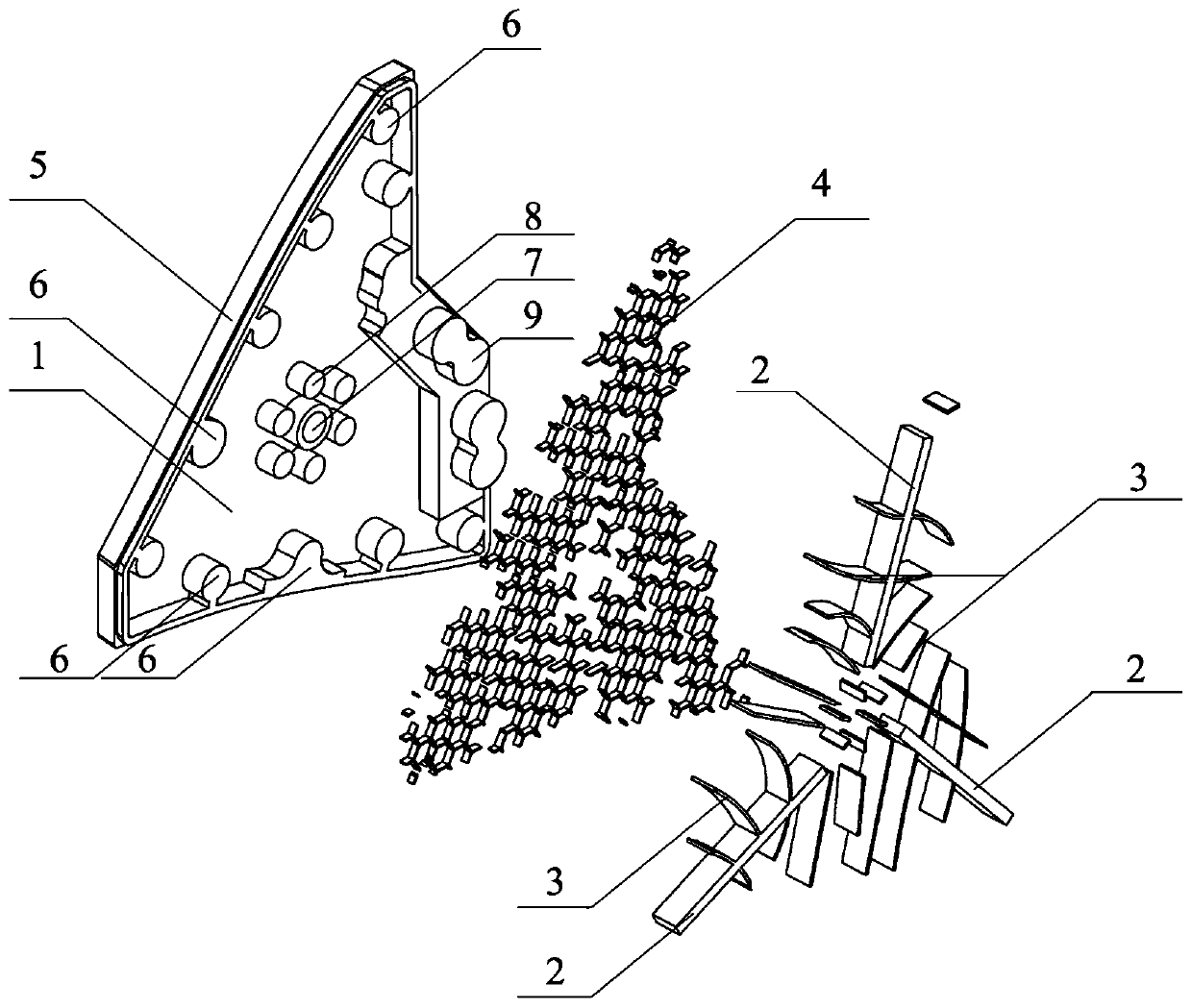

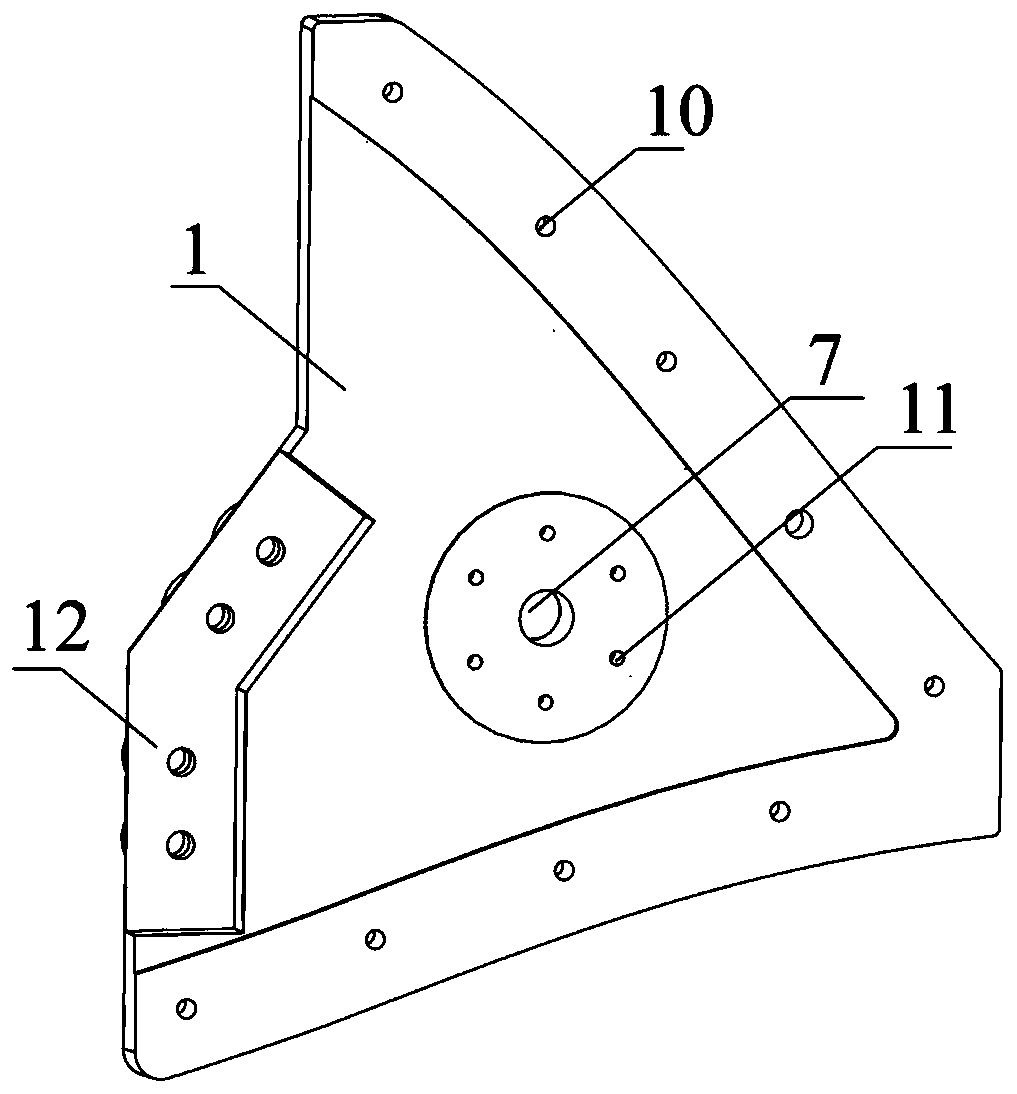

[0023] The invention is a high-rigidity special-shaped tank head structure reinforced by multi-level curved ribs of leaf vein type, which is characterized in that it comprises a triangular-like concave polygon head wall plate 1, a main-level middle vein rib 2, and a main-level side vein rib. Strip 3, secondary lattice strip 5, sealing boss 6, sealing bolt table 7, pipe hole 8, pipe sealing bolt table 9, sealing bolt hole 10 and pipe sealing bolt hole 11.

[0024] The three main-stage mid-ribs 2 are perpendicular to the head wall 1, and have the same height as the sealing boss 5, and radiate outward from the center of the head wall 1 as a source, and terminate at the outline of the tank head respectively. The three corner points of the boundary connect the pipeline sealing bolt platform 8 with the surrounding sealing boss 5 or sealing bolt platform 6. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com