Electroplating device

A technology of electroplating device and cooling device, which is applied in the direction of current conduction device, plating tank, electrolysis process, etc., can solve the problems of slow plating speed and low efficiency, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

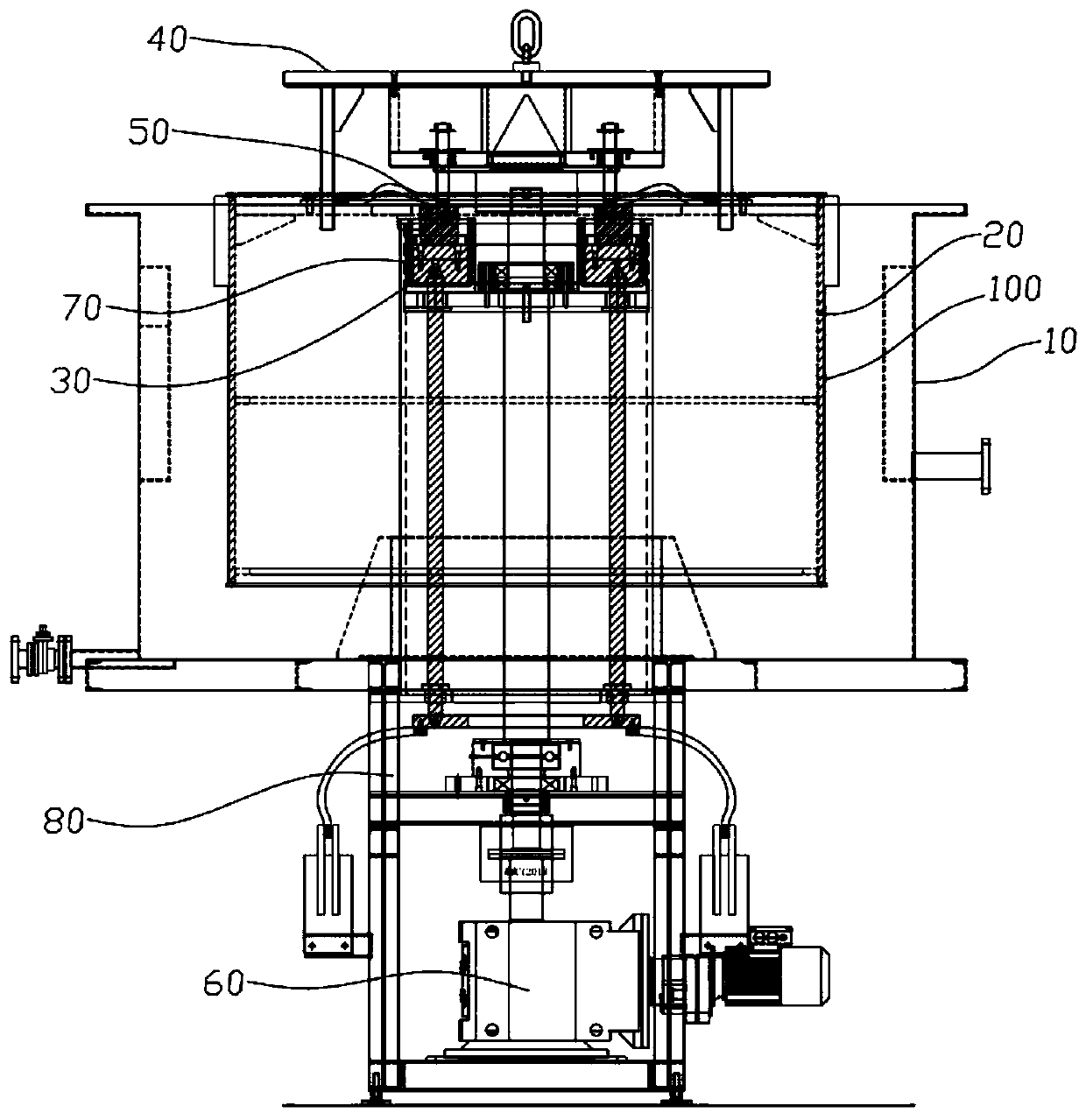

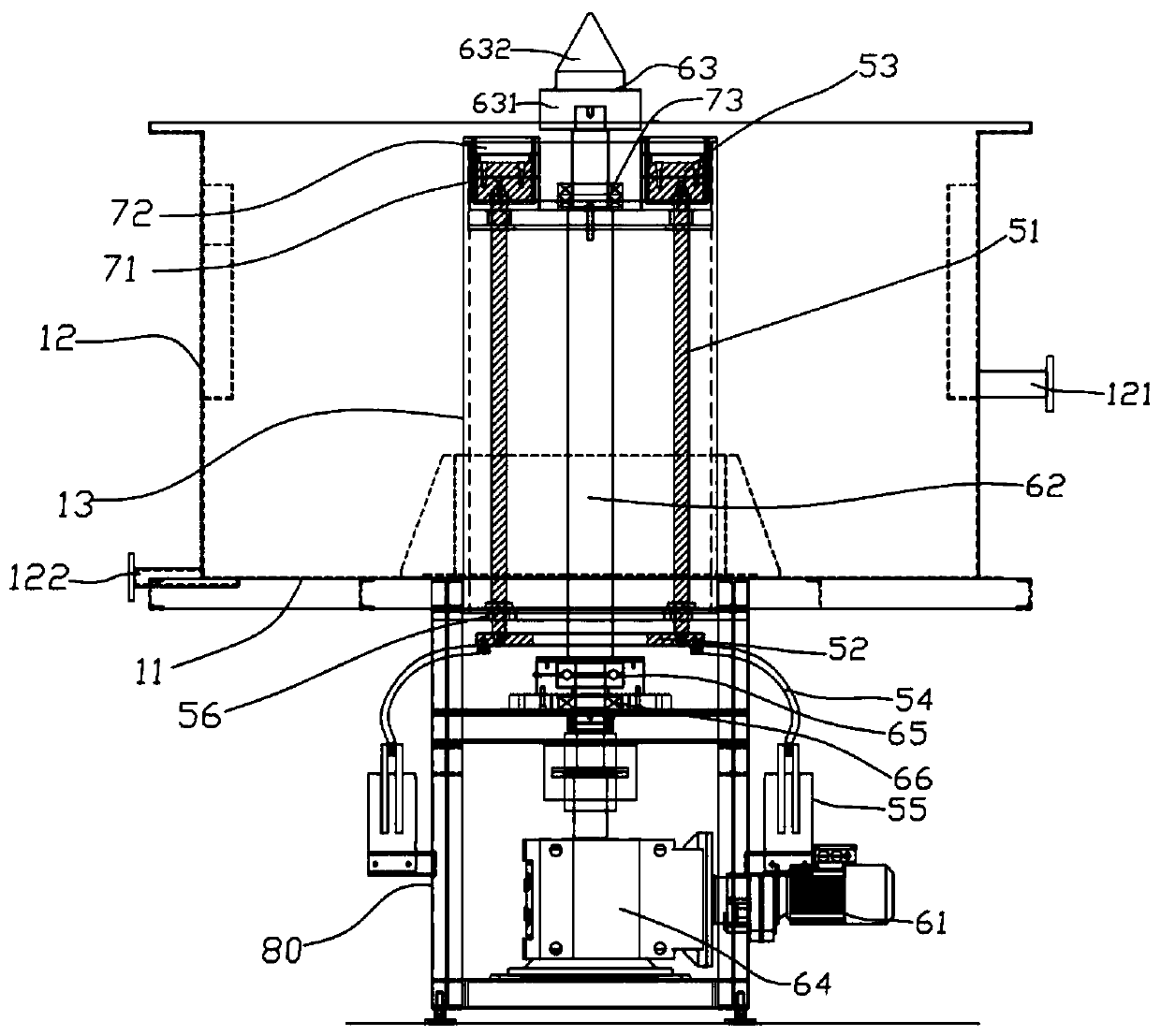

[0036] ginseng figure 1 Shown, the electroplating device in the present embodiment comprises:

[0037] The tank body 10 is formed with a hollow portion running through the bottom of the tank body 10 and an accommodating portion for placing the electroplating solution in the tank body 10;

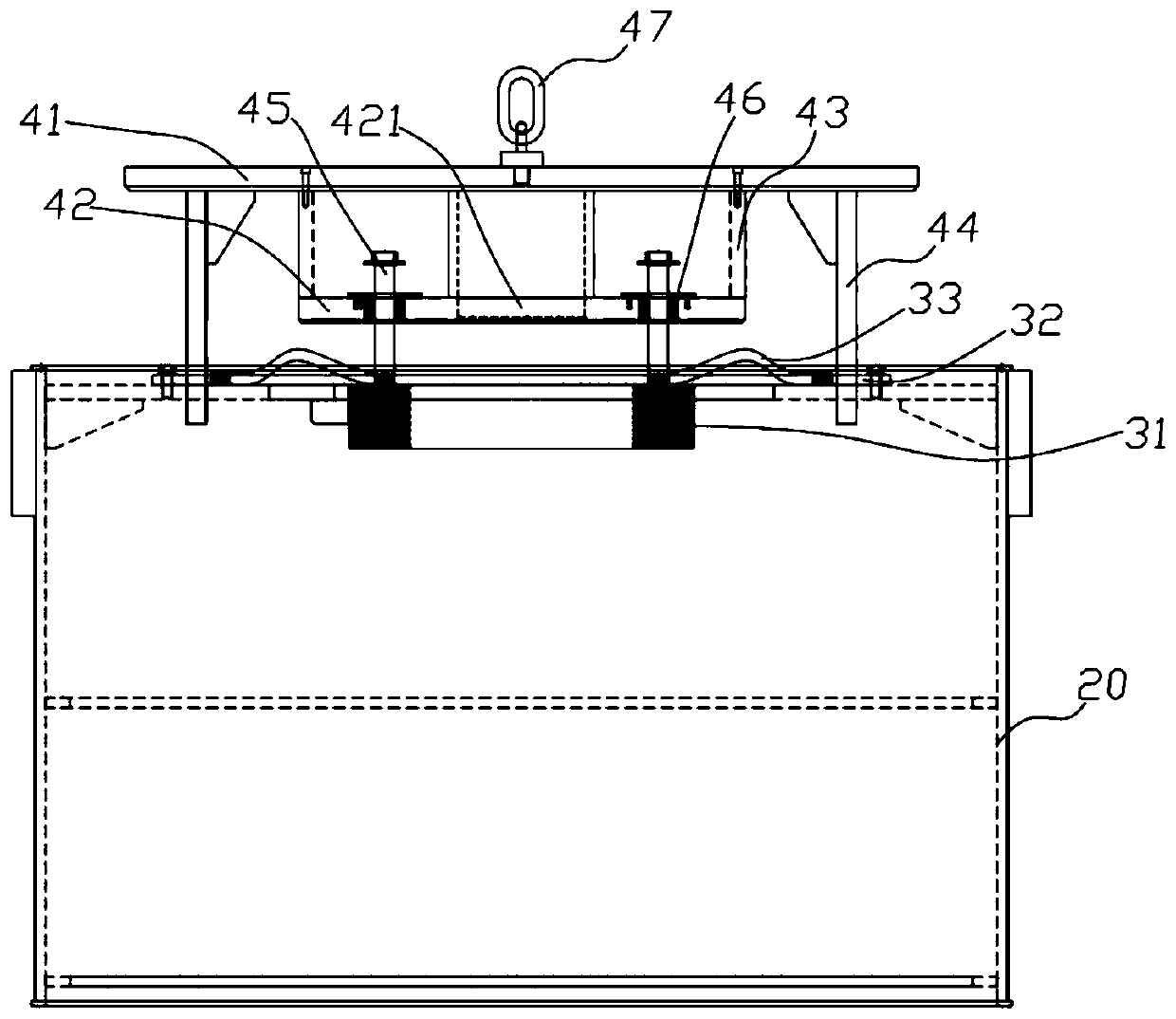

[0038] The tooling frame 20 is movably extended into the receiving part, and is used for installing the workpiece 100;

[0039] The first conductive component 30 is installed in cooperation with the tooling frame 20 and movably extends into the hollow part for guiding current;

[0040] The first bracket 40 is used to install the tooling frame 20 and the first conductive component 30;

[0041] The second conductive component 50 is fixedly extended into the hollow part and abuts against the first conductive component 30, for introducing and guiding current;

[0042] The driving assembly 60 , the driving assembly 60 abuts against the first bracket 40 through the hollow portion, and is used t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap