Direct shear test device and method based on unloading effect

A test device and a technology of action, applied in the field of deformed body mechanics test, can solve the problems of precision and difficult operation of the instrument, inability to meet the requirements of soil sample shear strength parameters, long test time, etc., and achieve the effect of uniform and stable pressure application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

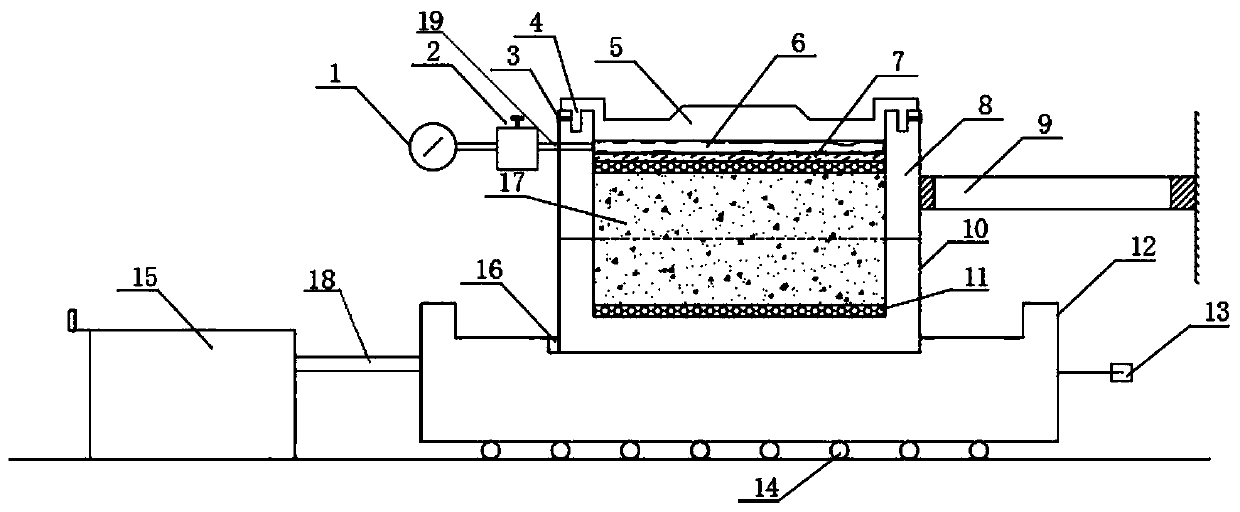

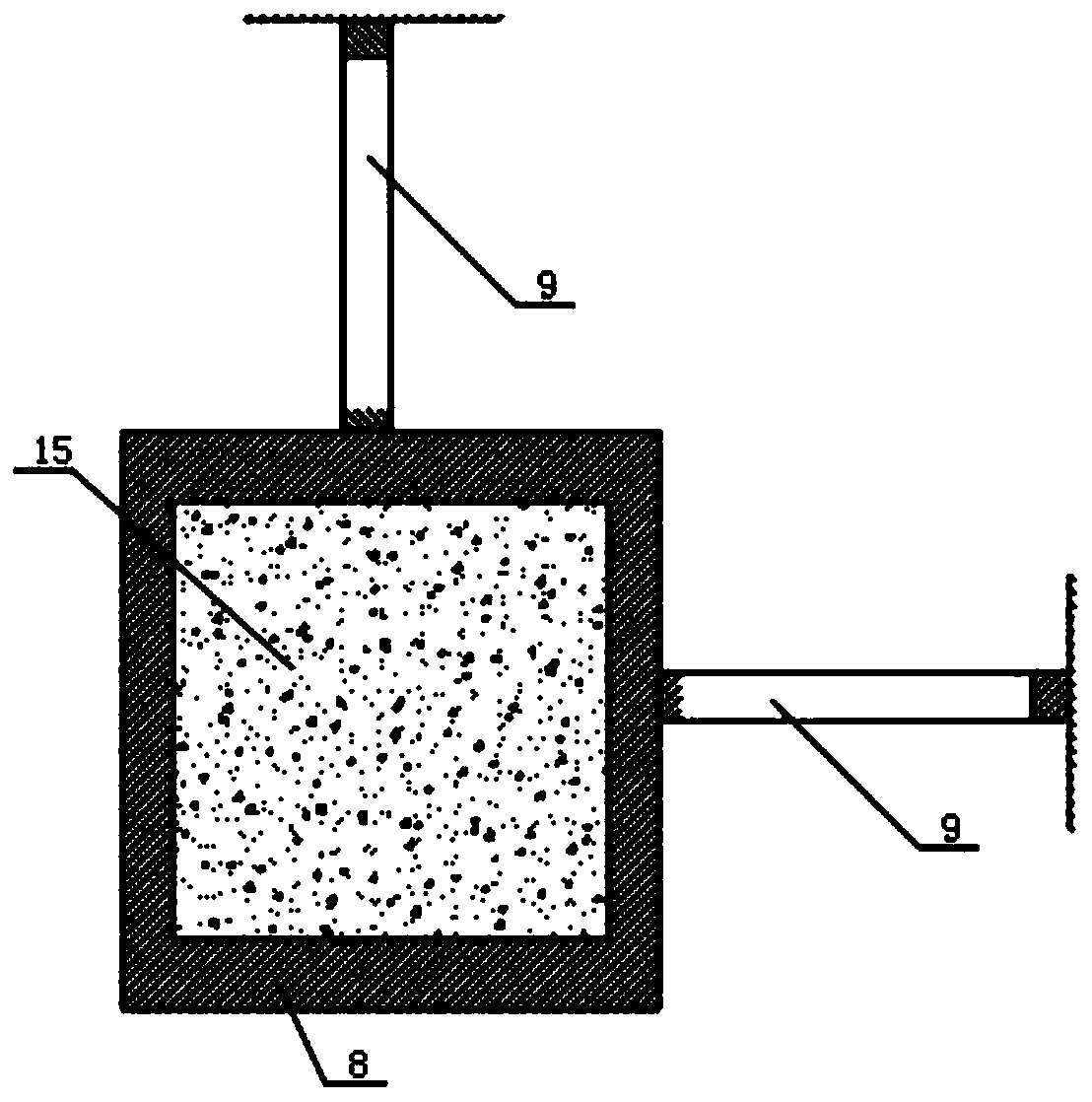

[0033] according to figure 1 with figure 2 The shown a kind of direct shear test device based on unloading effect includes shear box, top plate 5, air bag 6, pressure transmission pad 7, fixing device 9, water absorption mechanism, air inlet pipe 19, horizontal pressurization mechanism and moving mechanism; The shearing box described above is composed of an upper box 8 and a lower box 10 to form a hollow box body, and the upper box 8 is connected to the lower box 10; the top plate 5 is connected to the top of the upper box 8; the air bag 6, the pressure transmission pad 7 and the water absorption mechanism It is arranged below the top plate 5 successively from top to bottom; the fixing device 9 is fixedly connected on the outer side wall of the upper box 8; the air bag 6 communicates with the air intake pipe 19 passing through the side wall of the upper box 8; On the moving mechanism: the horizontal pressing mechanism is horizontally connected to the side wall of the moving ...

Embodiment 2

[0041] according to figure 1 with figure 2 A kind of direct shear test device based on the unloading effect shown is different from the first embodiment in that: the upper end surface of the upper box 8 side wall is provided with a limit groove 4, and the outer edge of the bottom surface of the top plate 5 is provided with a The protrusion matching the limit groove 4.

[0042] In actual use, the top plate 5 is clamped in the limiting groove 4 on the upper end surface of the side wall of the upper box 8 through the protrusion provided on the outer edge of the lower bottom surface of the top plate 5, and then fixed.

[0043] The present invention adopts the technical solution to make the top plate 5 and the upper box 8 stably connected, so as to ensure the accuracy of the test data of the test.

Embodiment 3

[0045] according to figure 1 A kind of direct shear test device based on unloading effect shown is different from embodiment one in that it also includes air pressure gauge 1 and air pressure valve 2; described air pressure gauge 1 and air pressure valve 2 are arranged outside the shear box and Connect with the intake pipe 19.

[0046] In actual use, the setting of the barometer 1 can grasp the value of the pressure applied to the air bag 6 in time. When the pressure value reaches the preset value, the air pressure valve 2 will be closed to obtain and record relevant tests and test data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com