Numerical control stepping rotating wheel

A wheel and rotor technology, applied in the field of CNC stepping and rotating wheels, can solve the problems of being very tired, living and living difficulties of disadvantaged groups, and having no self-driving function, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

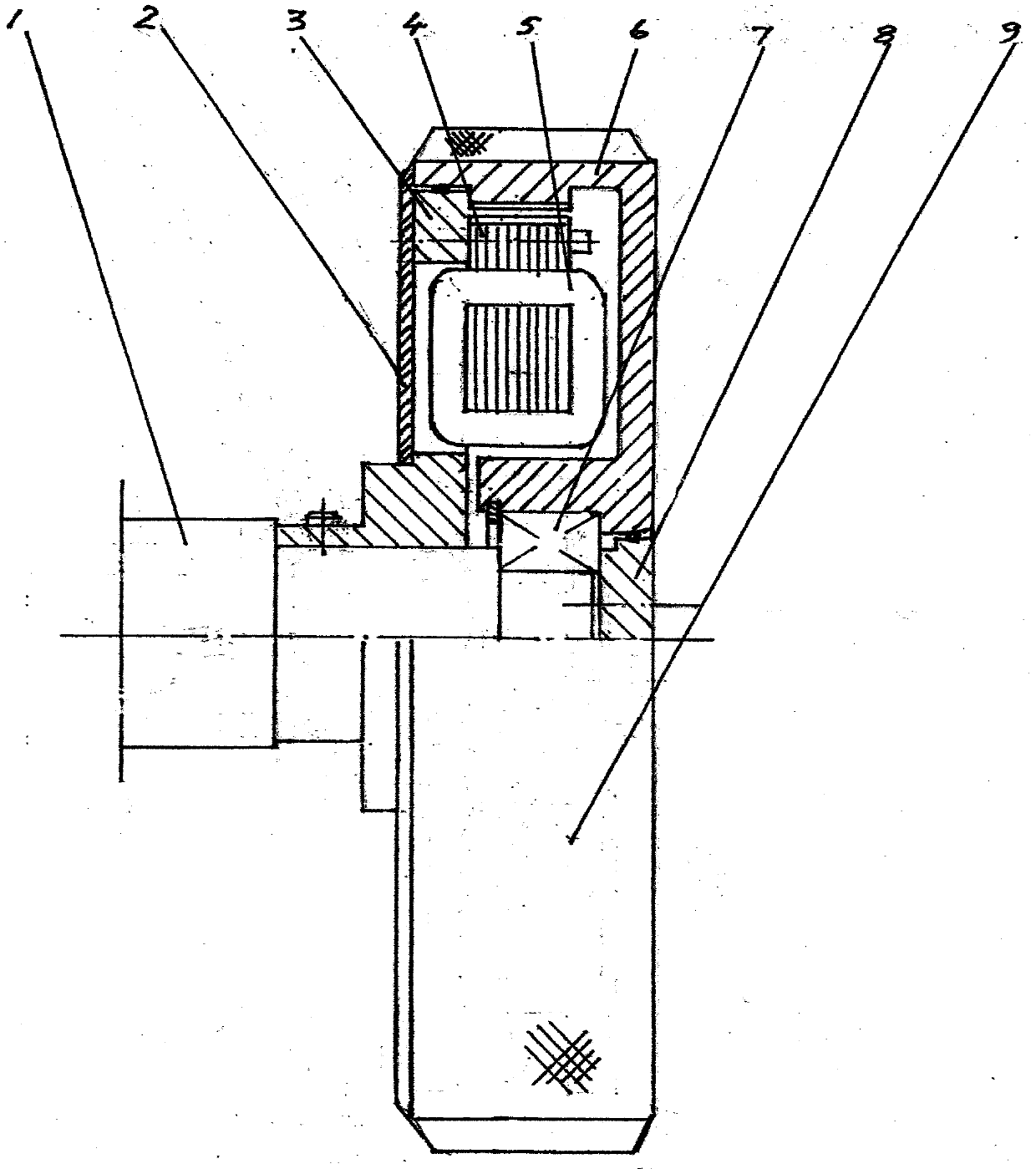

[0011] exist figure 1 Among them, the main shaft (1) is equipped with a stator mounting plate (3), the stator core (4) and the stator winding (5) are installed on the stator mounting plate (3), and the surface of the magnetic shoe is processed with flat teeth, which is the stator; on the main shaft ( 1) A bearing (7) is installed at the end, and a runner (6) is installed on the bearing (7), and a rubber wheel is installed on the outer ring of the runner (6), and the inner hole is processed into a flat tooth, which is the rotor and is set on the stator .The rotor tooth surface is concentric with the stator tooth surface and forms an annular gap "e".

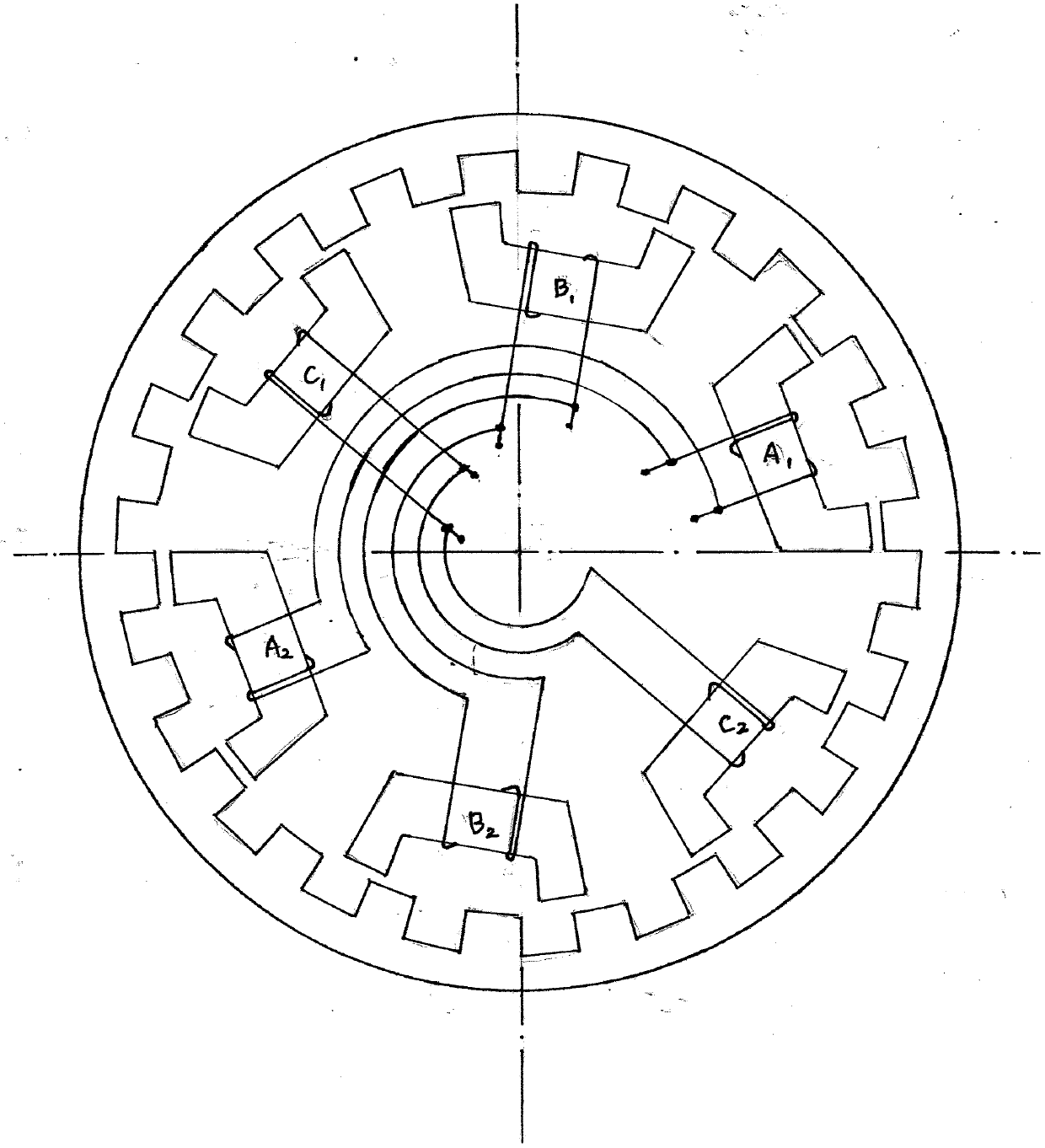

[0012] exist figure 2 In the shown embodiment, the stator mounting plate (3) is equipped with A1, A2, B1, B2, C1, C2 three-phase six stator windings, wherein A1 and B1 are misaligned by -1 / 3 teeth, and B1 and C1 are misaligned by -1 / 3 3 teeth; A2 and B2 misaligned - 1 / 3 teeth, B2 and C2 misaligned - 1 / 3 teeth. Each phase (name...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com