Universal testing machine

A technology of universal testing machine and test head, applied in the field of universal testing machine, can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

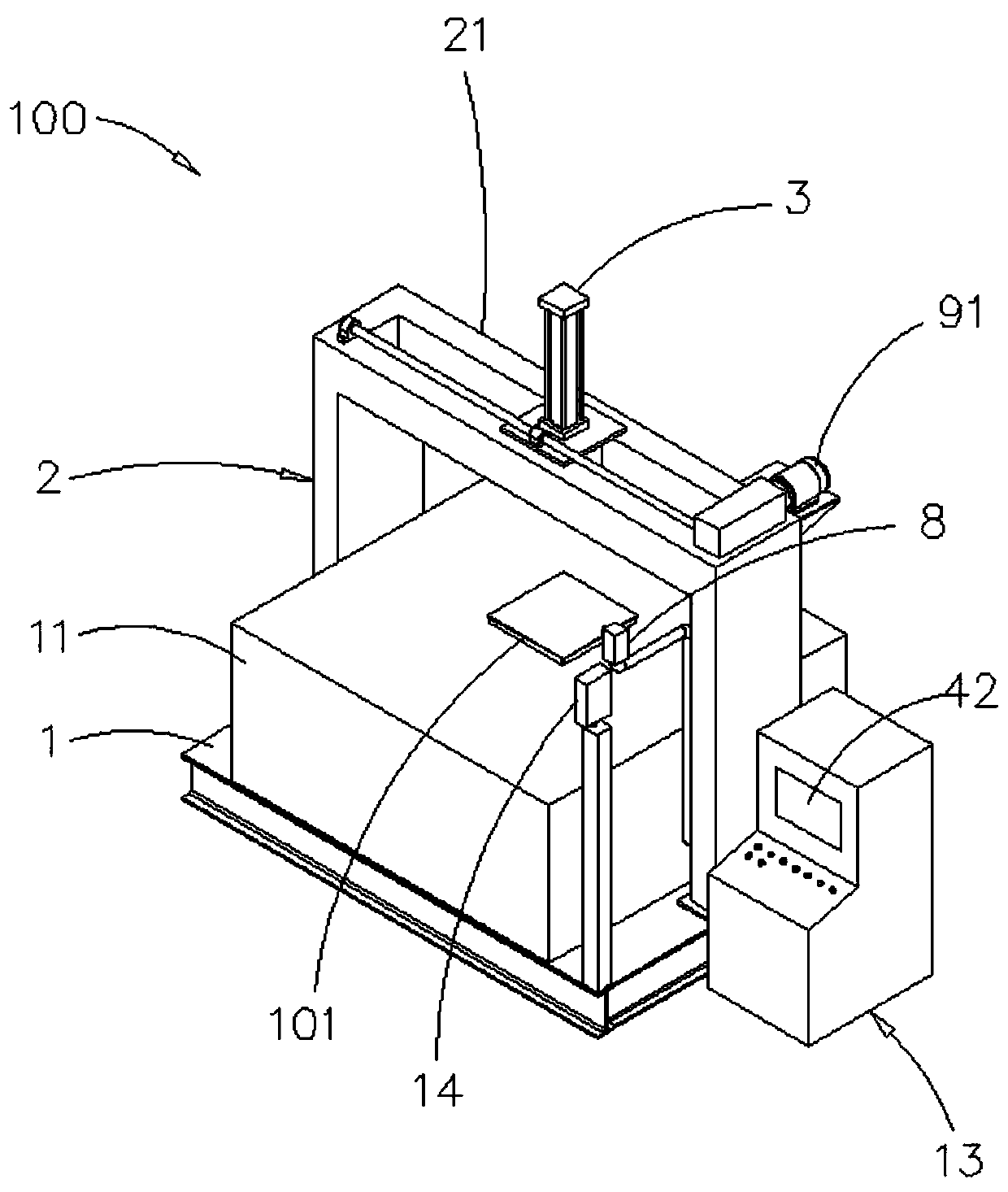

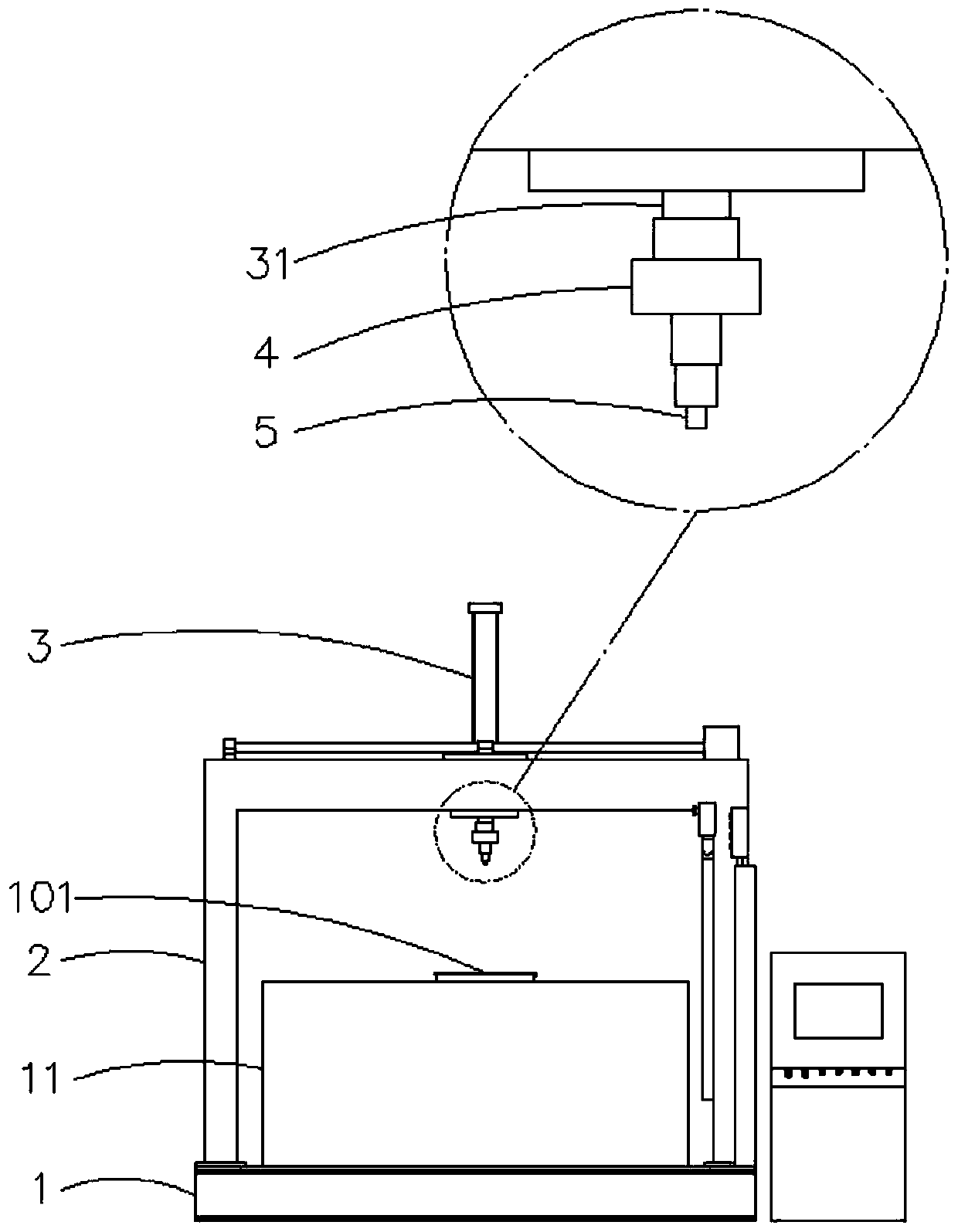

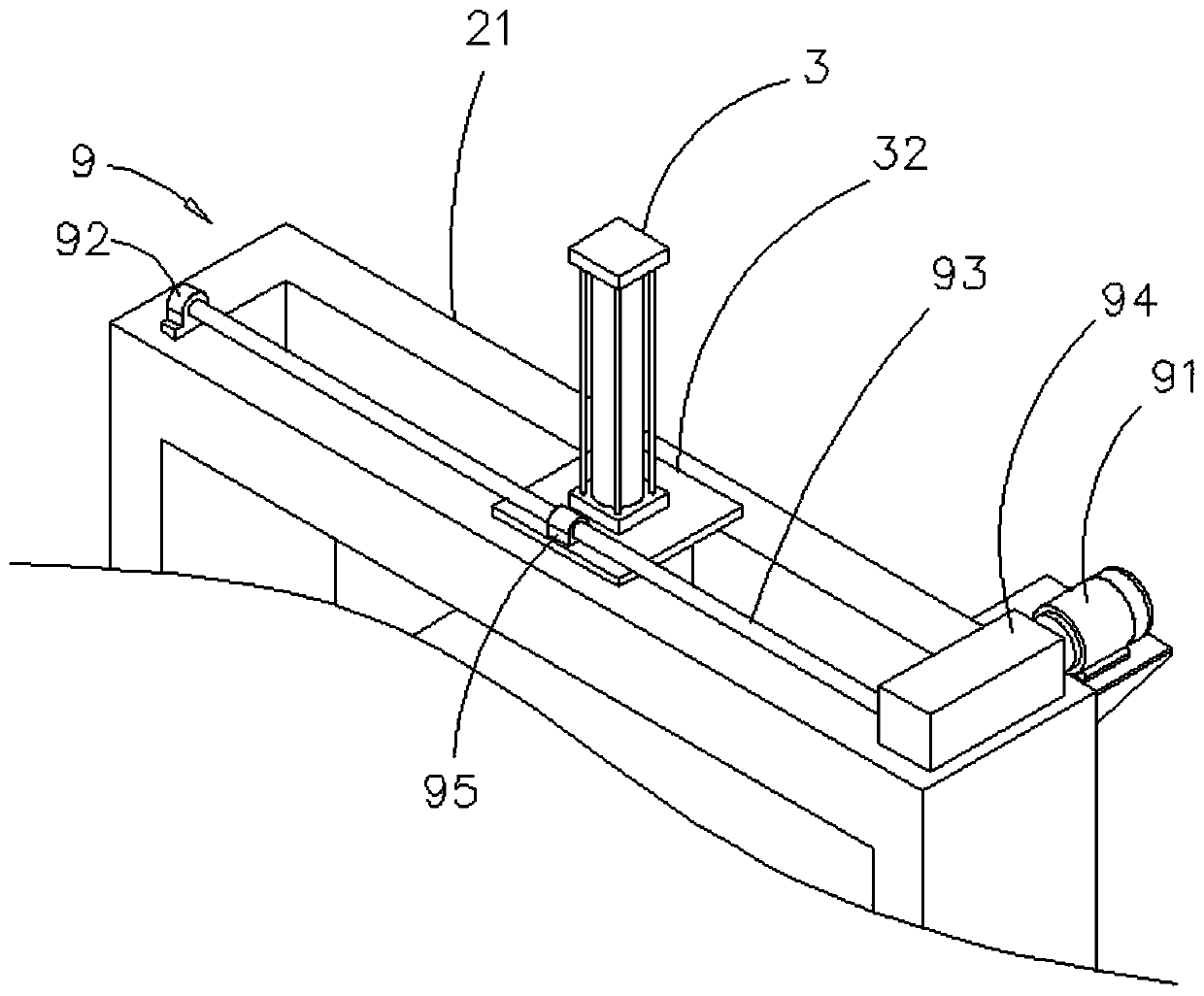

[0030] Such as Figure 1-3 and Figure 6 As shown, a kind of universal testing machine 100 of the present invention comprises: a test platform 1, is used to place a tested component 101; And a support 2, is located on the test platform 1, and the top of support is provided with a track 21; And a The lifting hydraulic cylinder 3 is arranged on the rail 21 to move left and right, and has a downwardly telescopic lifting hydraulic axis 31; and a load cell 4, which is arranged at the bottom end of the lifting hydraulic axis 31; and a test head 5 , located at the bottom of the load cell 4, used to contact the tested component 101; the load cell 4 is used to test the force between the test head 5 and the tested component 101 to obtain a test value; and a hydraulic machine 6, connected to the lifting hydraulic cylinder 3; and a first switch 7 connected to the hydra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap