Chemical plant online safety diagnosis and accident disposal guidance method and system

A chemical plant and accident technology, applied in the field of chemical plant online safety diagnosis and accident handling guidance method and system, can solve the problem of limited improvement of chemical plant safety, low degree of automation of chemical plant safety system, and inability to comprehensively diagnose chemical plants Safety status and other issues to achieve the effect of improving safety and reducing accident losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

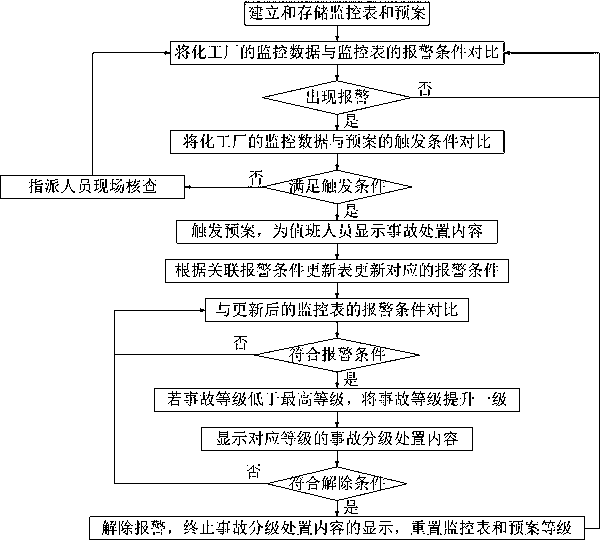

[0023] A chemical plant online safety diagnosis and accident handling guidance method, such as figure 1 shown, including the following steps:

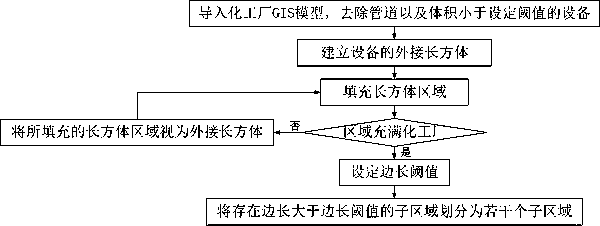

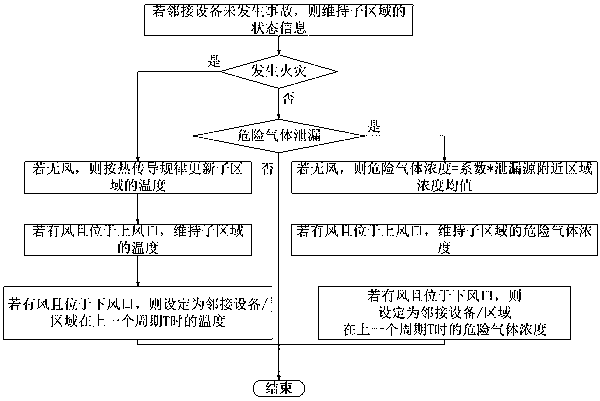

[0024] A') According to the GIS model of the chemical plant, the area between the chemical plant equipment and between the equipment and the building is divided into sub-areas, and an area table is established for each sub-area. The area table includes the area position, adjacent equipment, adjacent area, adjacent building and Status information, the status information of the area table includes temperature, concentration of dangerous gas, type of dangerous gas, wind direction and wind force. Such as figure 2 As shown, the method of dividing the sub-area includes: A'1) importing the GIS model of the chemical plant, removing the pipeline and the equipment whose volume is smaller than the set threshold; A'2) establishing the circumscribed cuboid of the equipment; Fill the cuboid area between the factory buildings, so that the cuboid a...

Embodiment 2

[0035] This embodiment is further improved on the basis of Embodiment 1. In step A'5 of this embodiment, a second side length threshold is also set, and the second side length threshold is that accidents occurring in the chemical plant area are dangerous When the gas leaks, under the condition of no wind, the distance that the leakage center spreads within T time; use the side length threshold and the second side length threshold respectively to divide and save the sub-regions; when a fire occurs in the chemical plant area, Use the sub-area corresponding to the side length threshold. When a dangerous gas leak occurs in the chemical plant area, use the sub-area corresponding to the second side length threshold. If fire and dangerous gas leakage occur at the same time, select the side length threshold and the second side length The division of subregions corresponding to smaller values in the threshold. This embodiment adopts different side length thresholds, which can improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com