Filling system of burnt ice cream

A technology of ice cream and filling unit, which is applied in the field of burning ice cream filling system, which can solve the problems of reducing work efficiency and achieve the effect of avoiding the parking of the box body, ensuring the filling time, and facilitating the accurate positioning of the filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

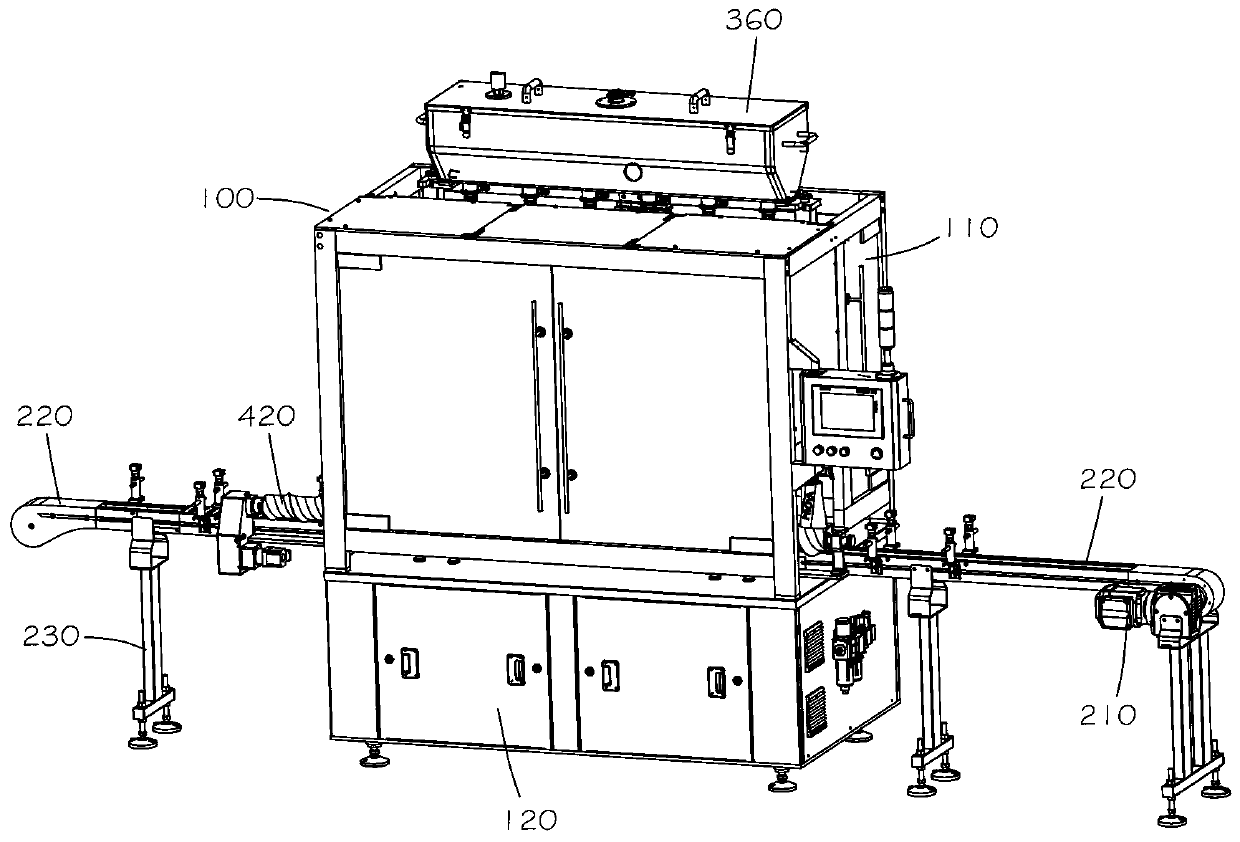

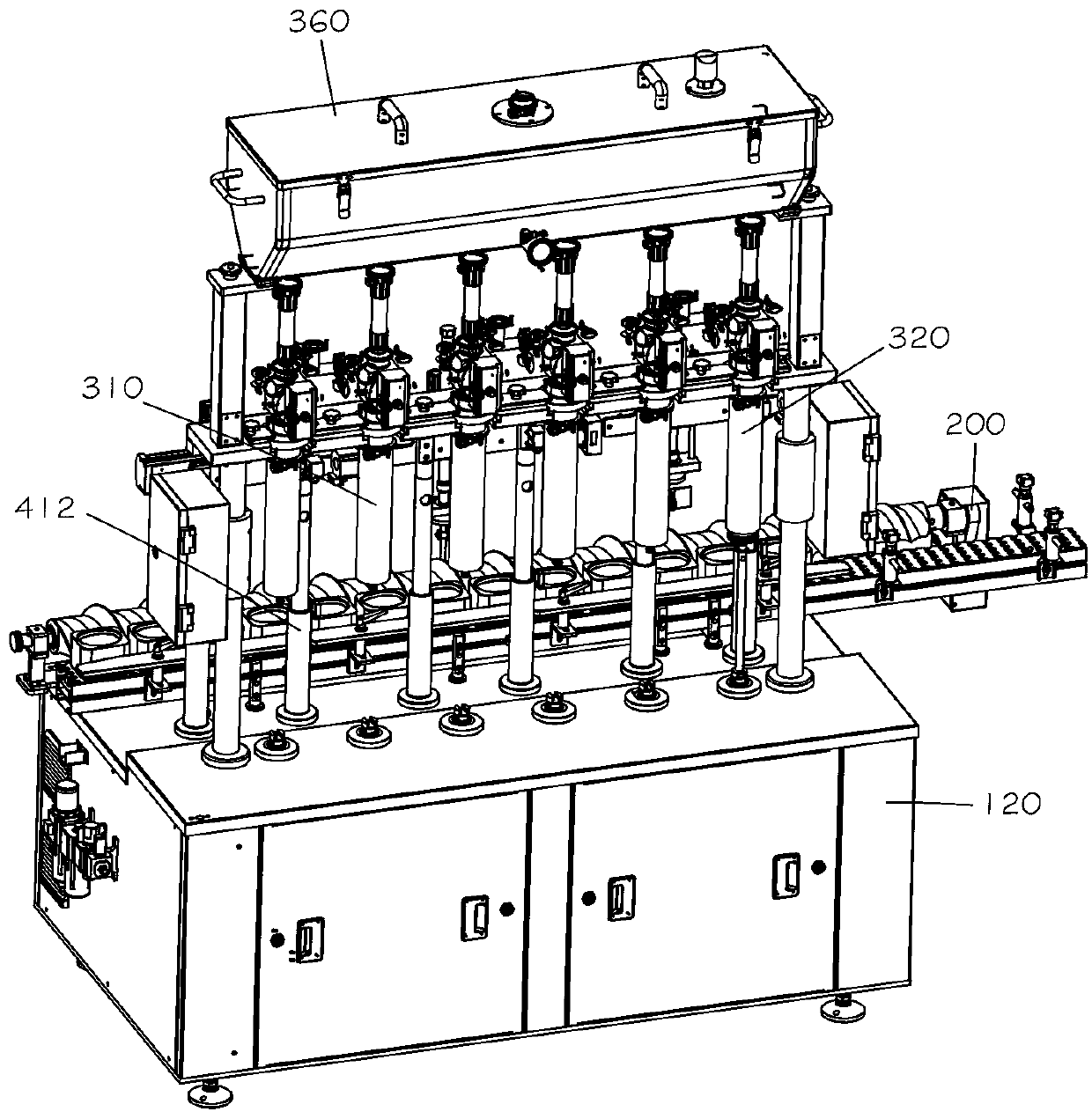

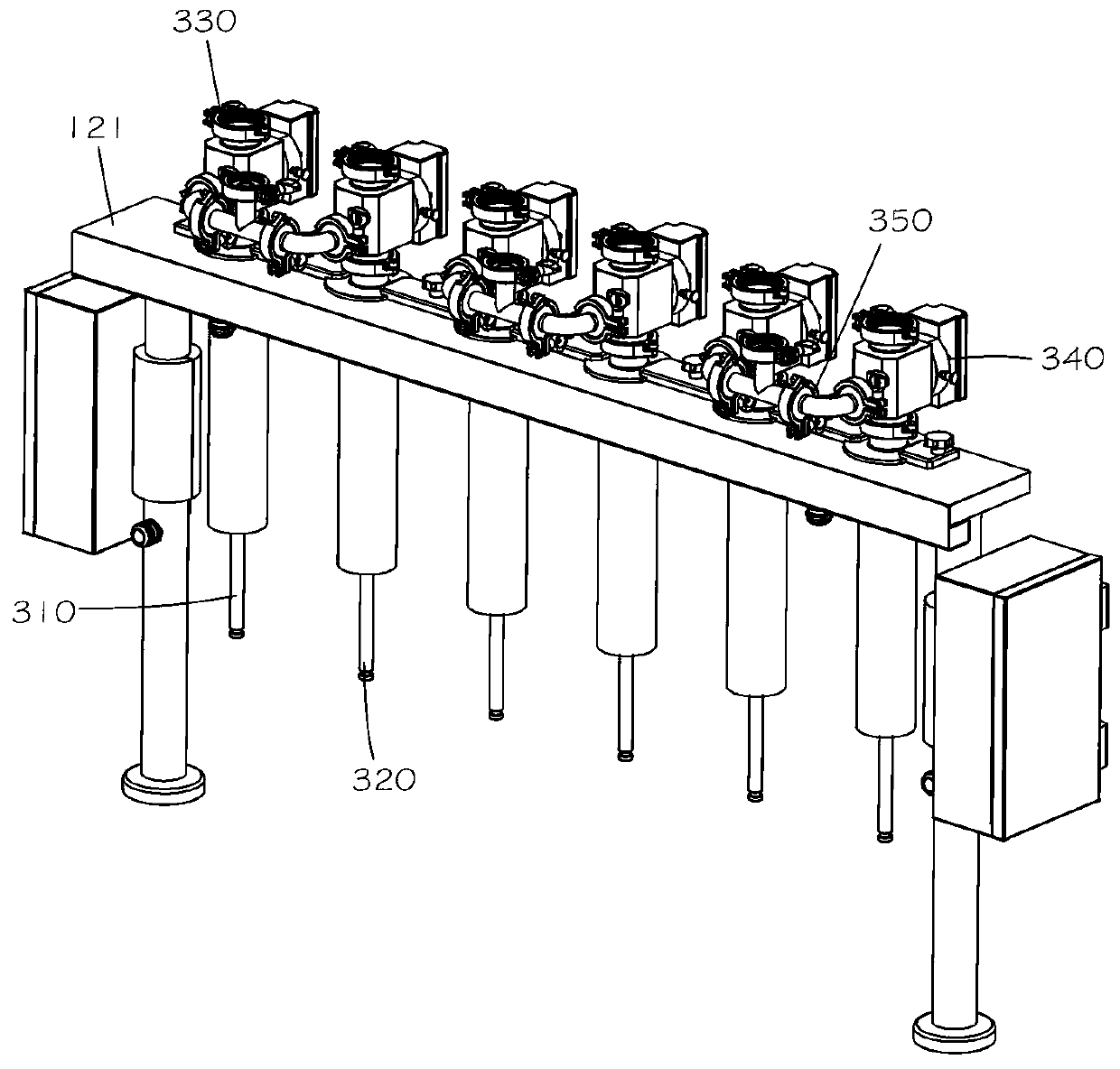

[0034] like Figures 1 to 13 The shown fire ice cream pouring system of the present invention includes a main body part 100 , a transmission part 200 , a storage part 300 and a pouring part 400 . The transmission part 200 is used to transmit the ice cream box 500 , and the transmission part 200 is connected to two sides of the main body 100 . The storage part 300 is used for storing the ice cream raw materials, and the pouring part 400 is used for squeezing the ice cream raw materials into the ice cream box body 500 . The empty box body 500 moves under the guidance of the transmission part 200 , and when passing through the position of the main body part 100 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap