Pipe extrusion type quick eccentricity adjusting operation method

A technology of squeeze tube type and operation method, which is applied in the field of tube squeeze type quick eccentric adjustment operation method, which can solve the problems of waste of die adjustment machine head material, power loss of conductor core wire, cumbersome actions, and unguaranteed accuracy. Achieve the effect of saving mold adjustment accuracy, shortening learning time, and reducing production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

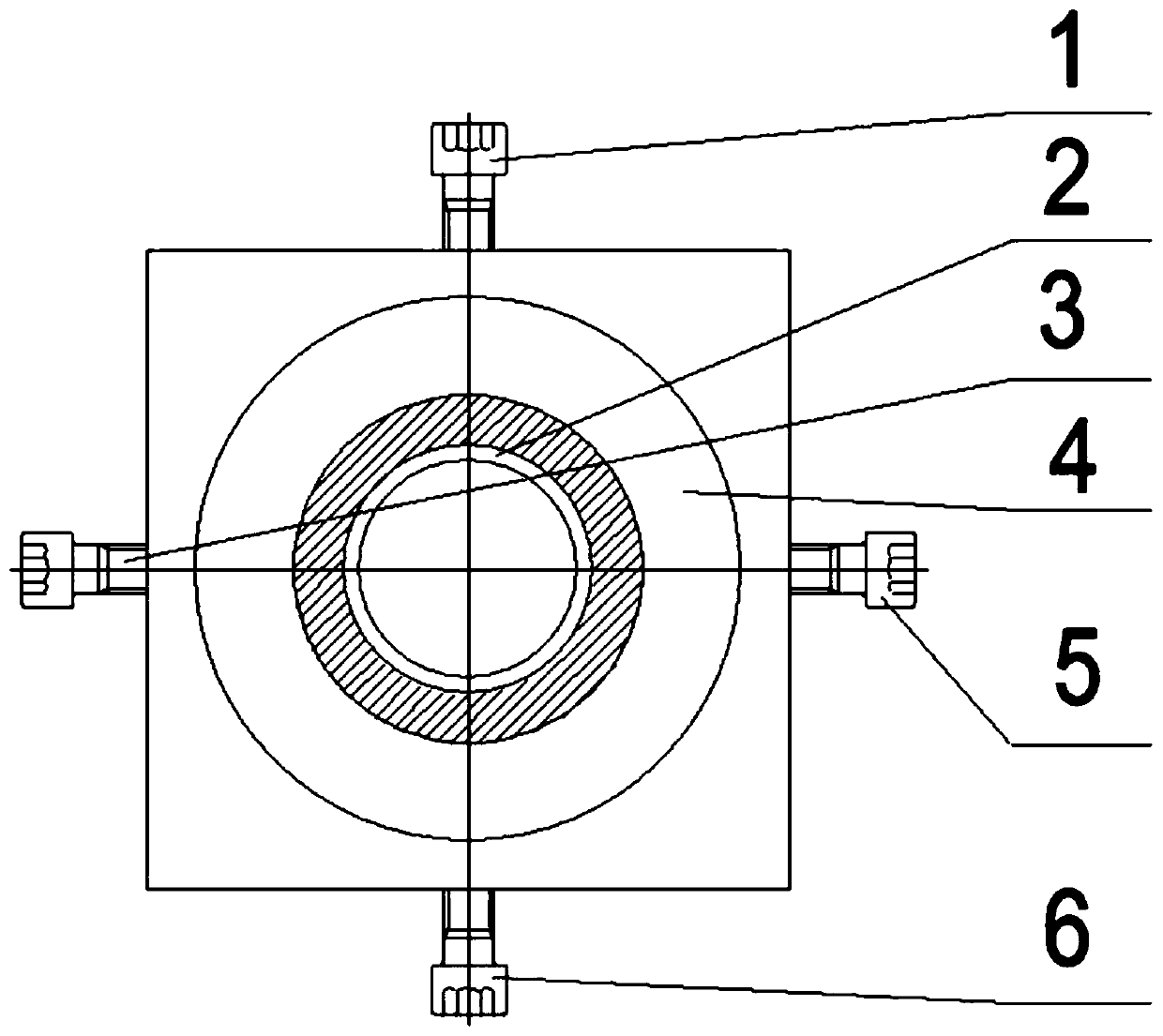

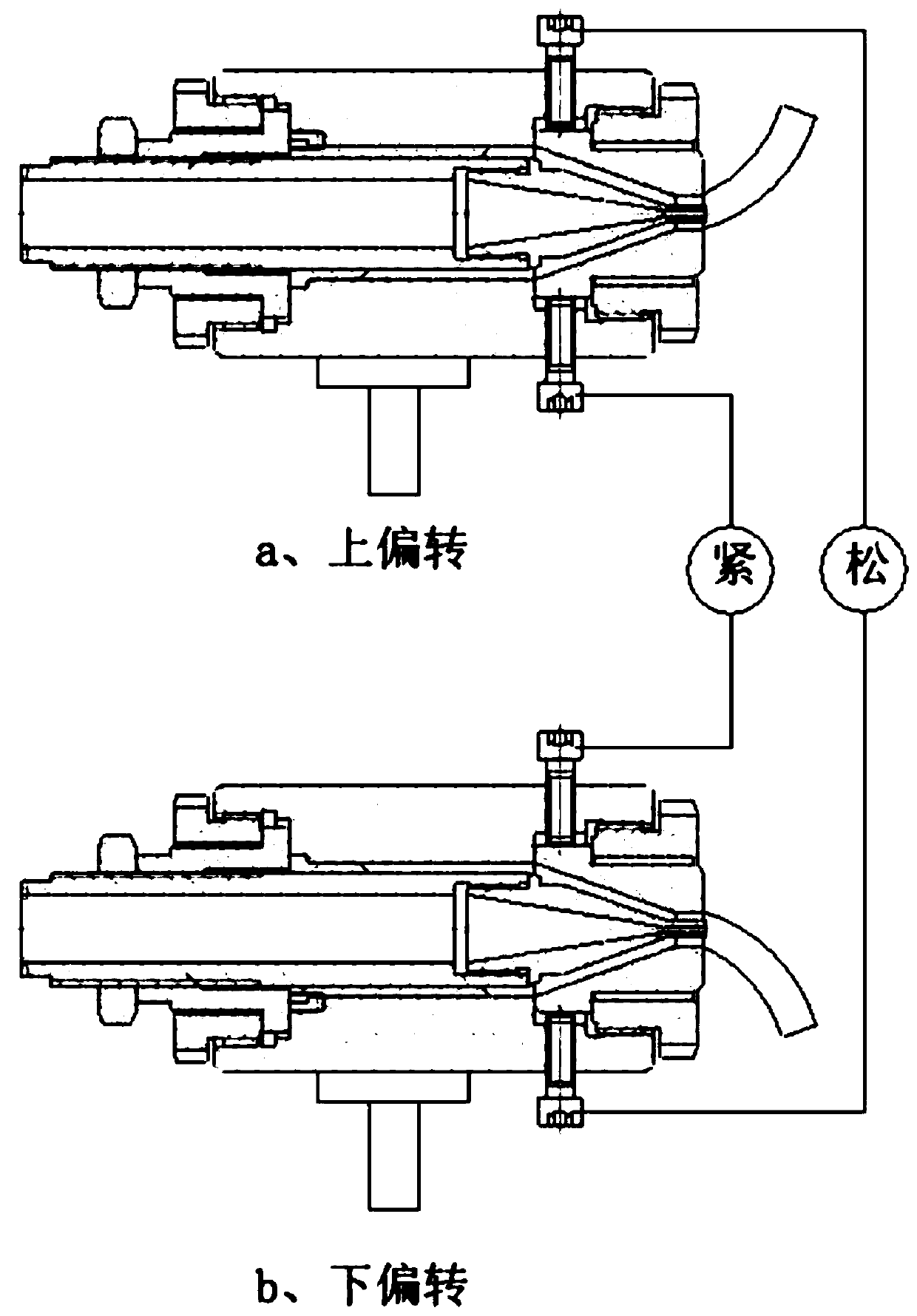

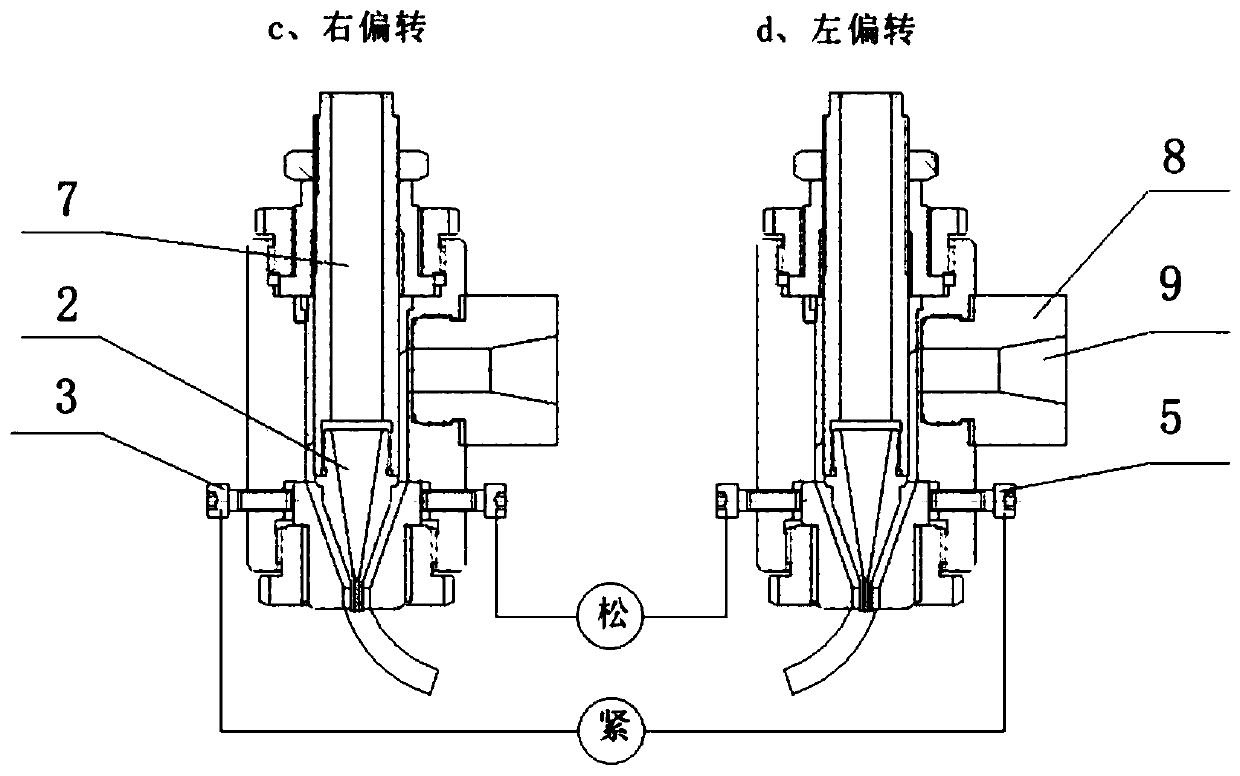

[0044] A kind of squeezing tube type fast eccentric adjustment operation method (see attached Figures 1 to 4 ),include

[0045] Step 1. The preheated mold core 2 is installed on the mold core seat 7, and the mold sleeve gland 11 is installed to compress the mold sleeve. The end face of the extruded tube core mouth protrudes from the end face of the mold sleeve 4 or is equal to the end face of the mold sleeve mouth. ,

[0046] Step 2. Observe that the distance or gap between the mold core and the mold sleeve is adjusted evenly, and then tighten the mold adjustment screw.

[0047] Step 3: Start the extruder host to make the plastic tube extrude from the mold, observe the changes of the extruded tube 10 instantly,

[0048] Step 4, adjust the mold adjusting screw,

[0049] Step 5. Cross-sectional cutting verification until the instantaneously extruded tubes flow out symmetrically and parallelly and then droop;

[0050] Step 6: After passing the verification, the conductor / cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com