A TPO waterproofing membrane with temperature regulating function and preparation method thereof

A technology for waterproofing membranes and temperature regulation, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of yellowing of the outer surface, difficulty in ensuring energy saving effect, and poor temperature regulation effect, etc. Achieve the effect of saving energy consumption, reducing usage, and comfortable indoor living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

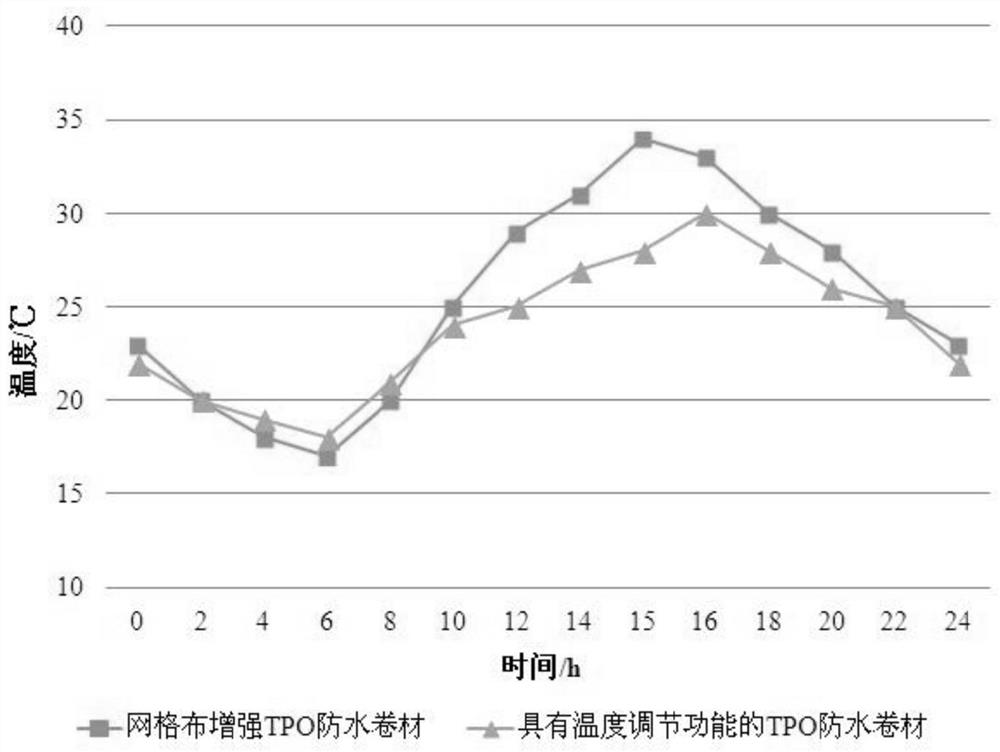

[0041] like figure 1 As shown in the figure, a TPO waterproof membrane with temperature adjustment function includes a bottom layer 1 and a surface layer 2, wherein the bottom layer 1 is a homogeneous TPO waterproof membrane with a thickness of 1.2 mm and a width of 2 m, and the surface layer 2 is a phase change energy storage material. The polypropylene non-woven fabric, the phase change energy storage material includes 0.5kg of polyethylene glycol, 0.5kg of paraffin and 0.7kg of myristic acid, the weight average molecular weight of polyethylene glycol is 4000, and the weight of polypropylene non-woven fabric is 100g / m 2 ;

[0042] The preparation method of the coil comprises the following steps:

[0043] S1: Preparation of temperature-regulating functional emulsion

[0044] S11: Add 0.15kg of cationic emulsifier alkyl propylene diamine, 10kg of deionized water and 1.7kg of phase change energy storage material at 110°C into the high-speed shearing machine, and emulsify at ...

Embodiment 2

[0052] like figure 1 As shown in the figure, a TPO waterproof membrane with temperature adjustment function includes a bottom layer 1 and a surface layer 2, wherein the bottom layer is a grid cloth reinforced TPO waterproof membrane with a thickness of 1.5mm and a width of 2m, and the surface layer is a phase change energy storage material. The polyester non-woven fabric, the phase change energy storage material includes 0.5kg of polyethylene glycol, 0.4kg of paraffin and 0.5kg of myristic acid, the weight average molecular weight of polyethylene glycol is 4000, and the weight of polyester non-woven fabric is 100g / m 2 ;

[0053] The preparation method of the coil comprises the following steps:

[0054] S1: Preparation of temperature-regulating functional emulsion

[0055] S11: Add 0.2kg of cationic emulsifier alkyl propylene diamine, 10kg of deionized water and 1.4kg of phase change energy storage material at 100°C into the high-speed shearing machine, and emulsify at 5000r...

Embodiment 3

[0063] On the basis of Example 2, in order to facilitate construction and ensure the quality of the lap joint, a lap joint is reserved at the long edge of the coil with a width of 80-100 mm, and the adjacent coil is welded by hot air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap