High-rise pile cap retaining wall and construction method

A technology of high pile caps and construction methods, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of high foundation bearing capacity requirements, long construction period, high probability of problems, etc. The effect of small difficulty and small amount of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

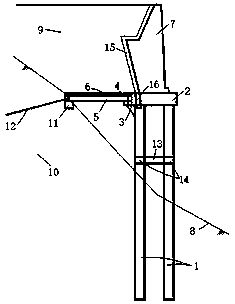

[0025] The invention provides a high pile cap retaining wall placed outside the fill slope, including a double-row pile foundation whose foundation is placed below the ground line and whose upper end extends to a certain height above the ground line. In the middle of the double-row pile foundation The transverse waist beam and longitudinal waist beam, the cap connected to the top of the double-row pile foundation, the corbel connected to the cap and the inner side of the double-row pile foundation, and the connecting beam placed on the corbel will connect the The pin connecting the tie beam and the corbel, the retaining plate placed on the tie beam, the foundation and the anchor rod on the inner side of the tie beam, the inner end is anchored into the anchor rod connected to the tie beam at the outer end of the stable slope, and the cap top face of the retaining wall.

[0026] In the present invention, the double-row pile foundation is used to connect the double-row pile found...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com