Four-drum shearer with capability of full-seam mining by layered cutting and mining

A layered mining, four-drum technology, applied in slitting machinery, cutting machinery, earth-moving drilling, etc., can solve the problem of reducing the power and size of the cutting mechanism, reducing the height of the shearer body, and excessive cutting impact, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

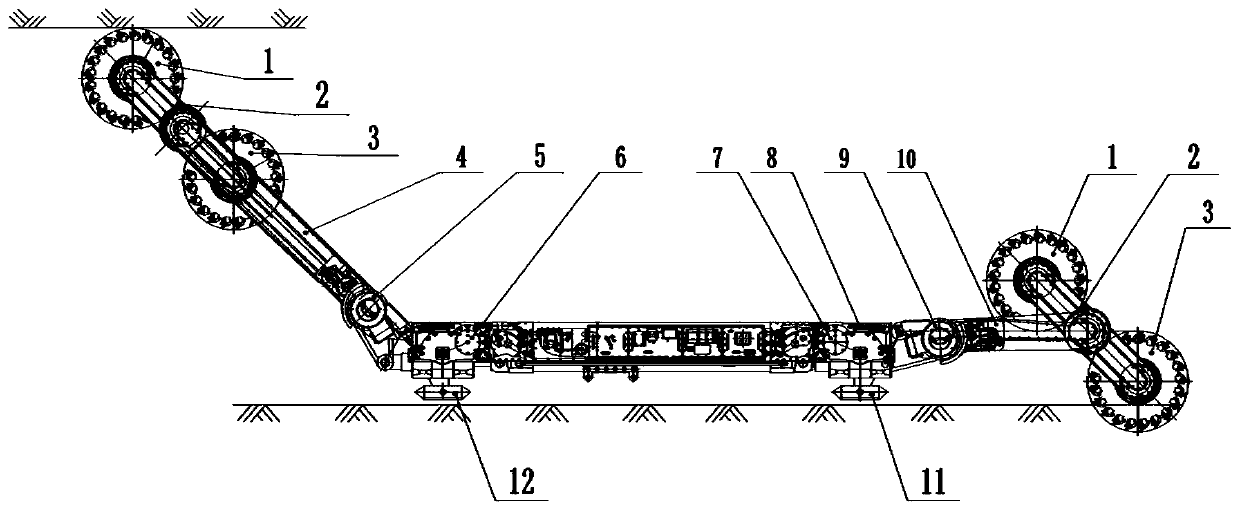

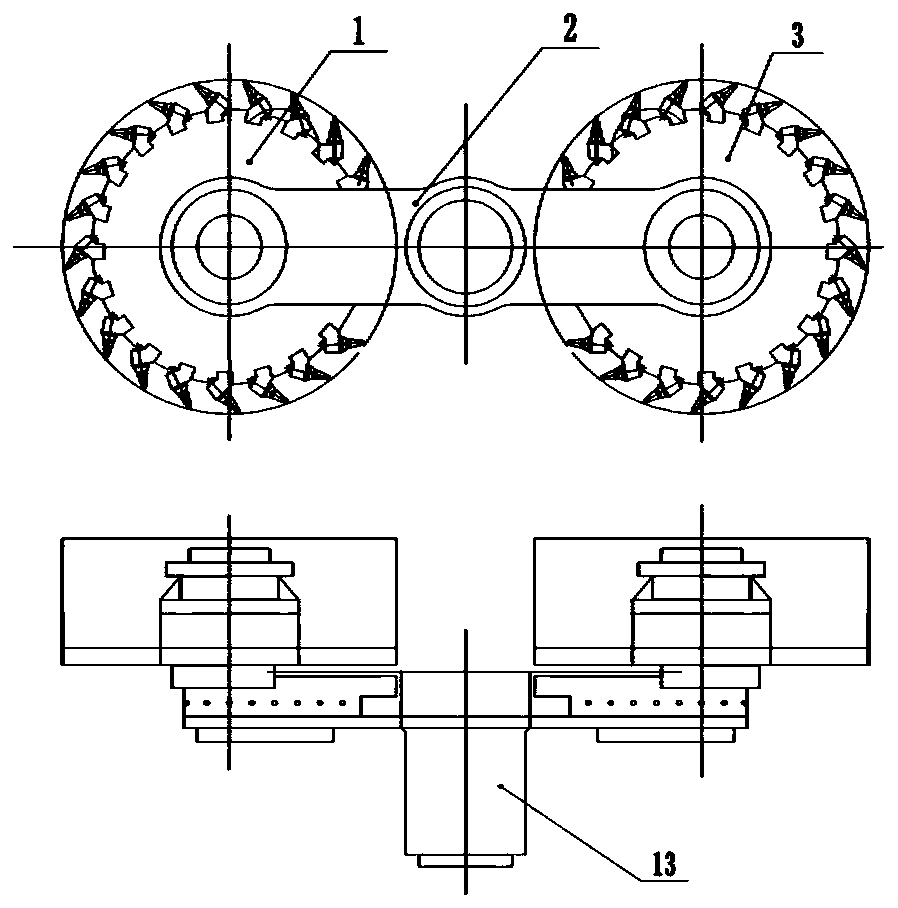

[0016] Such as Figure 1 to Figure 2 As shown, the layered mining four-drum shearer provided by the embodiment of the present invention includes a left travel part 6, a right travel part 7, a left cutting part 5, and a right cutting part 9, and the left travel part 6 and the left travel part Cutting part 5 is connected, and described right running part 7 is connected with described right cutting part 9, and described left running part (6) is connected with left cutting part (5) away from the end of right running part (7) rotation, so The left cutting part (5) includes a left rocker arm (4), a slewing arm (2), a left-handed drum (1), and a right-handed drum (3); the right walking part (7) is far away from the left walking part ( 6) The end is rotatably connected with a right cutting part (9), and the right cutting part (9) includes a right rocker arm (10), a revolving arm (2), a left-handed drum (1), and a right-handed drum (3).

[0017] Specifically, for the rotary arm (2) on...

Embodiment II

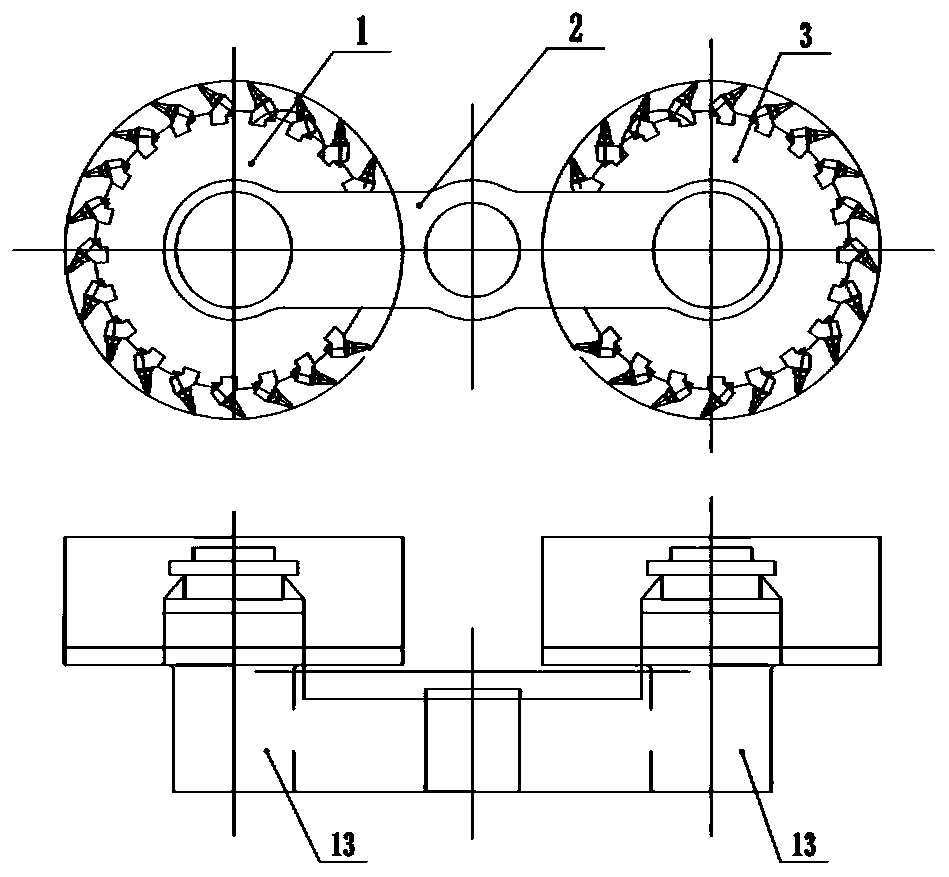

[0021] Such as figure 1 and image 3 As shown, the layered mining four-drum shearer provided by the embodiment of the present invention includes a left travel part 6, a right travel part 7, a left cutting part 5, and a right cutting part 9, and the left travel part 6 and the left travel part Cutting part 5 is connected, and described right running part 7 is connected with described right cutting part 9, and described left running part (6) is connected with left cutting part (5) away from the end of right running part (7) rotation, so The left cutting part (5) includes a left rocker arm (4), a slewing arm (2), a left-handed drum (1), and a right-handed drum (3); the right walking part (7) is far away from the left walking part ( 6) The end is rotatably connected with a right cutting part (9), and the right cutting part (9) includes a right rocker arm (10), a revolving arm (2), a left-handed drum (1), and a right-handed drum (3).

[0022] Specifically, the rotary arm (2) on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com