Auxiliary multi-direction adjusting device for industrial video detection and adjusting method thereof

A technology for video detection and adjustment devices, which is applied to measuring devices, parts of color TVs, parts of TV systems, etc. It can solve the problems of inconvenient product detection and inability to move industrial cameras in multiple directions, so as to improve practicability and The effects of stability, improved convenience, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

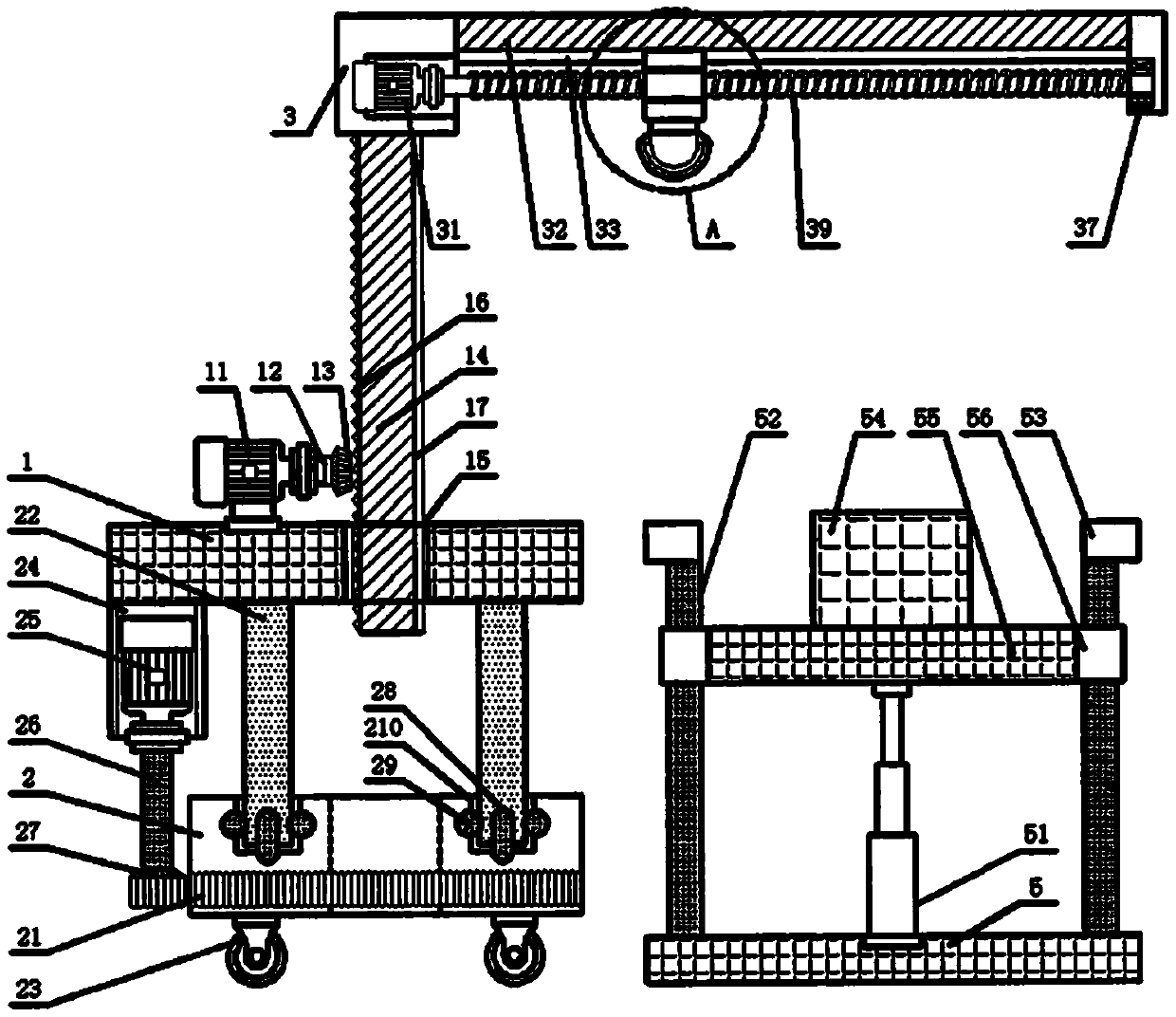

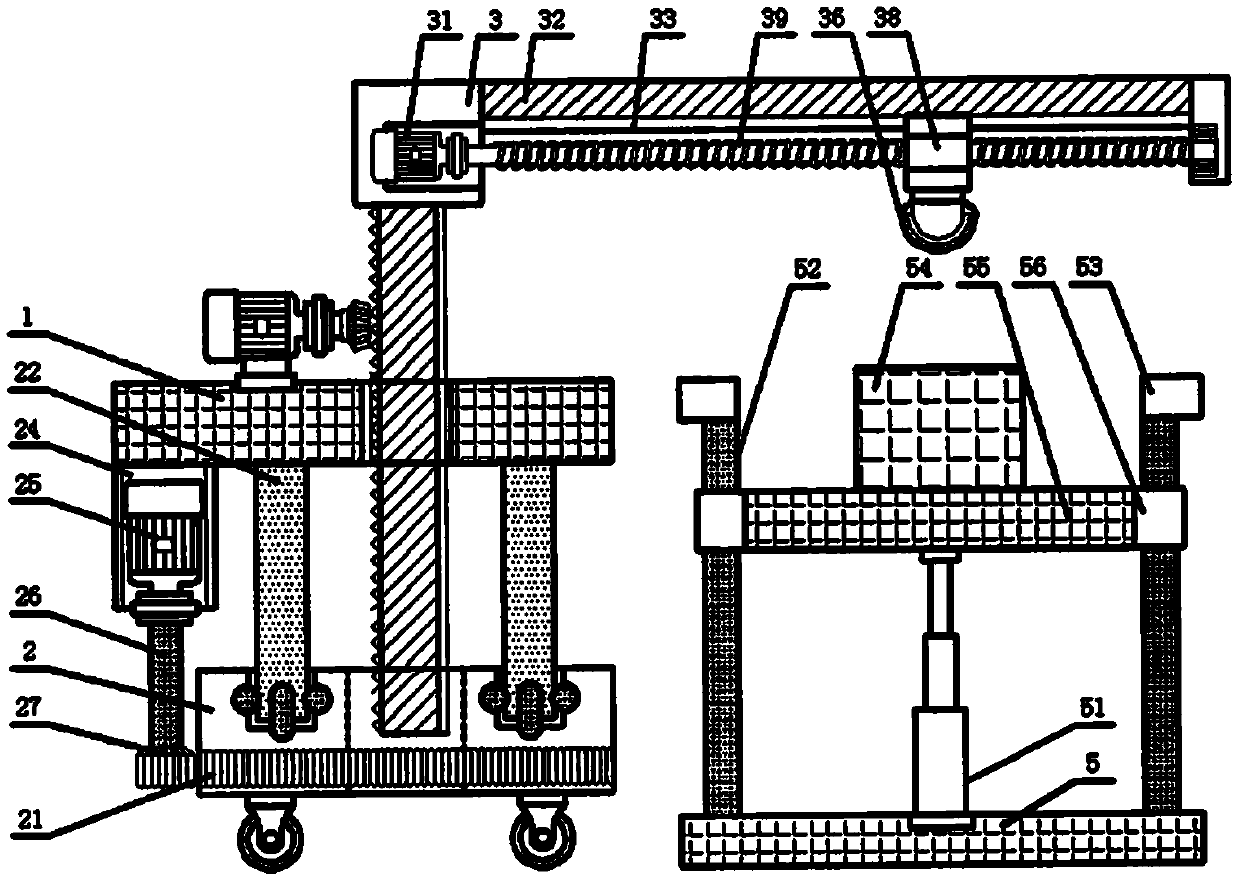

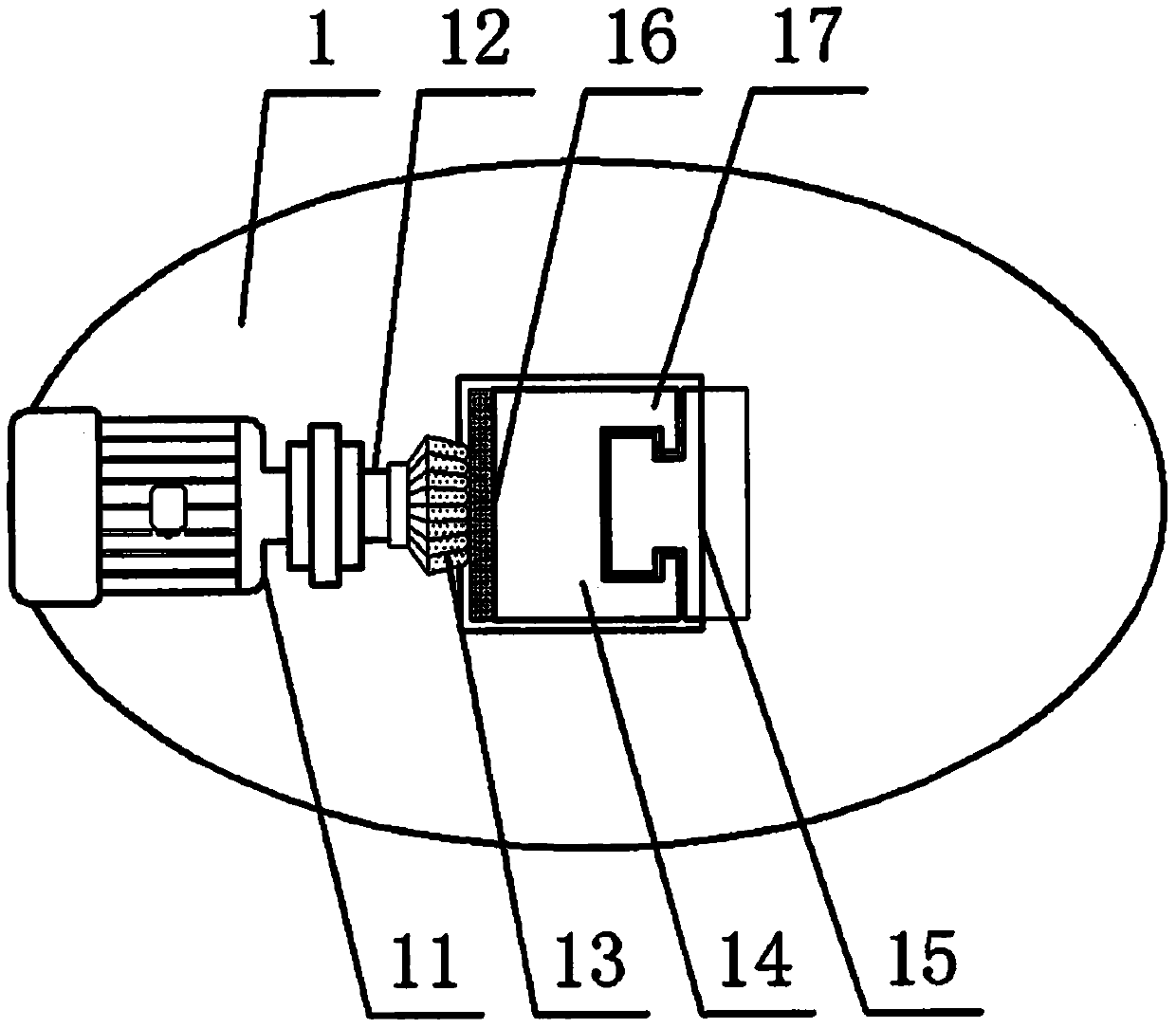

[0035] Embodiment 1: see Figure 1-6, an auxiliary multi-directional adjustment device for industrial video detection, including a support plate 1 and a base plate 2, the support plate 1 is in the shape of an oval plate, the base plate 2 is in the shape of a circular plate, the support plate 1 and the base plate 2 Placed parallel and horizontally up and down, and the support plate 1 is above the bottom plate 2; one side of the bottom surface of the support plate 1 is fixedly connected with a first motor barrel 24 with an open bottom surface, and the first motor barrel 24 is equipped with a motor with the output end facing downward. The first motor 25, the model of the first motor 25 is M-2IK6N-C, the first motor 25 is connected to the bottom of the bottom plate 2 through a transmission mechanism; the center of the top surface of the bottom plate 2 is recessed with a circular through hole 211, located at The outer side of the circular through hole 211 is recessed with an annula...

Embodiment 2

[0042] Example 2: see Figure 7 , in this embodiment, the present invention also proposes an adjustment method for an auxiliary multi-directional adjustment device for industrial video detection, including the following steps:

[0043] Step 1, the external power supply is respectively connected to the first motor wire, the second motor wire, the third motor wire, the telescopic cylinder wire, the camera power wire, and the camera switch controls the camera 36 to open;

[0044] Step 2, the telescopic cylinder switch controls the telescopic cylinder 51, and the telescopic rod of the telescopic cylinder 51 drives the loading plate 55 up and down through the connecting block, and the sliding cylinder 56 on the side of the loading plate 55 slides along the corresponding sliding rod 52, and the detection workpiece 54 is placed onto the loading plate 55;

[0045] Step 3, the first motor 25 is used with the support assembly through the transmission mechanism to drive the support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com