Plasma surgical equipment connector capable of meeting safe creepage distance

A connector and plasma technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problems of low stability and reliability of plasma surgery equipment, short creepage distance, damage to connectors and hosts, etc. , to enhance reliability and tensile strength, prevent creepage spread and avoid short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

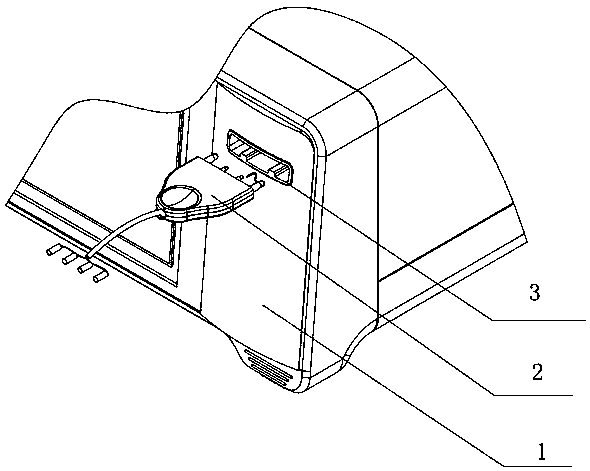

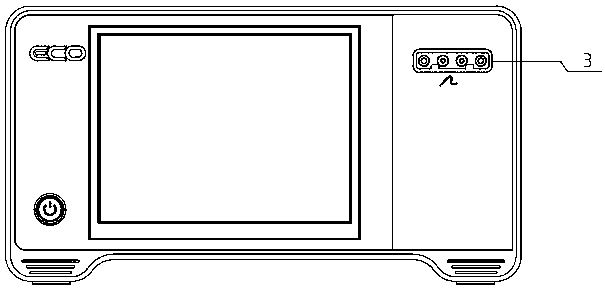

[0025] Such as figure 2 As shown, the connector of this embodiment is composed of a main body connector 2 and a receptacle connector 3 . The main body connector 2 is arranged at the tail of the plasma accessory; the socket connector 3, such as image 3 As shown, it can be fitted with the main body connector 2, and the socket connector is arranged on the panel of the main body 1 of the plasma surgical equipment.

[0026] Such as Figure 4 As shown, the main body connector 2 is composed of an insulating main body outer plastic shell and several main body connecting pins, the outer plastic shell is made of insulating ABS resin material, and a number of pins are provided inside to allow the pins to be inserted. hole, the pin is installed in the plastic case after being inserted into the socket. The contact parts of the above-mentioned plurality of main body connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com