A winter tire with a zigzag tread pattern

A kind of winter tire and zigzag technology, which is applied to tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problems that cannot meet the needs of consumers for ice and snow grip performance, and achieve enhanced snow removal capacity, The effect of increasing the grip performance and improving the grip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

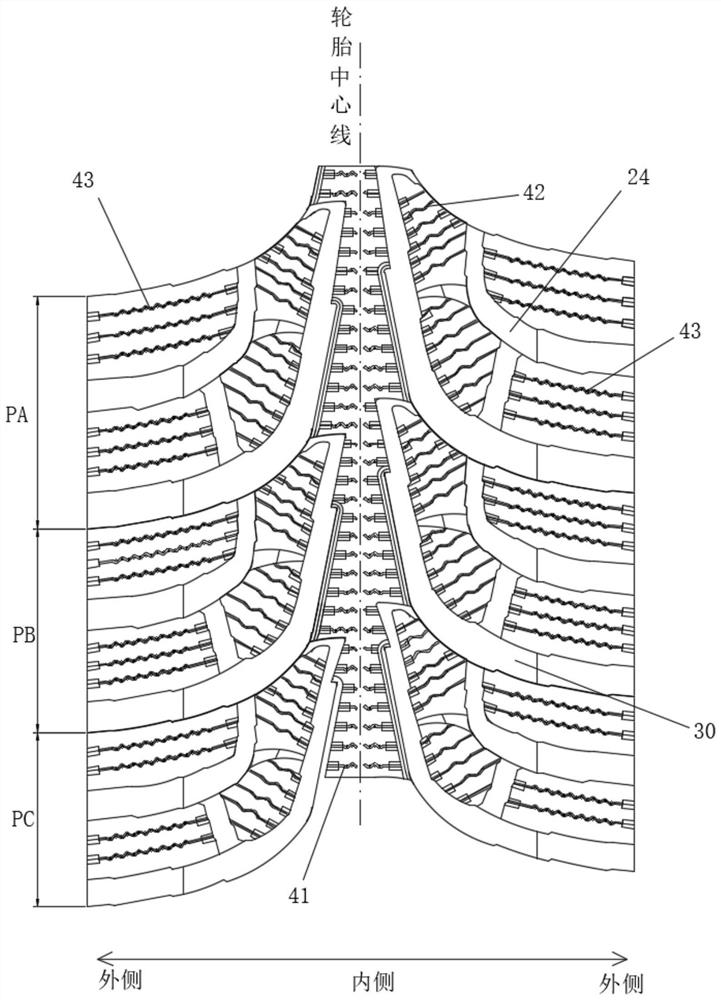

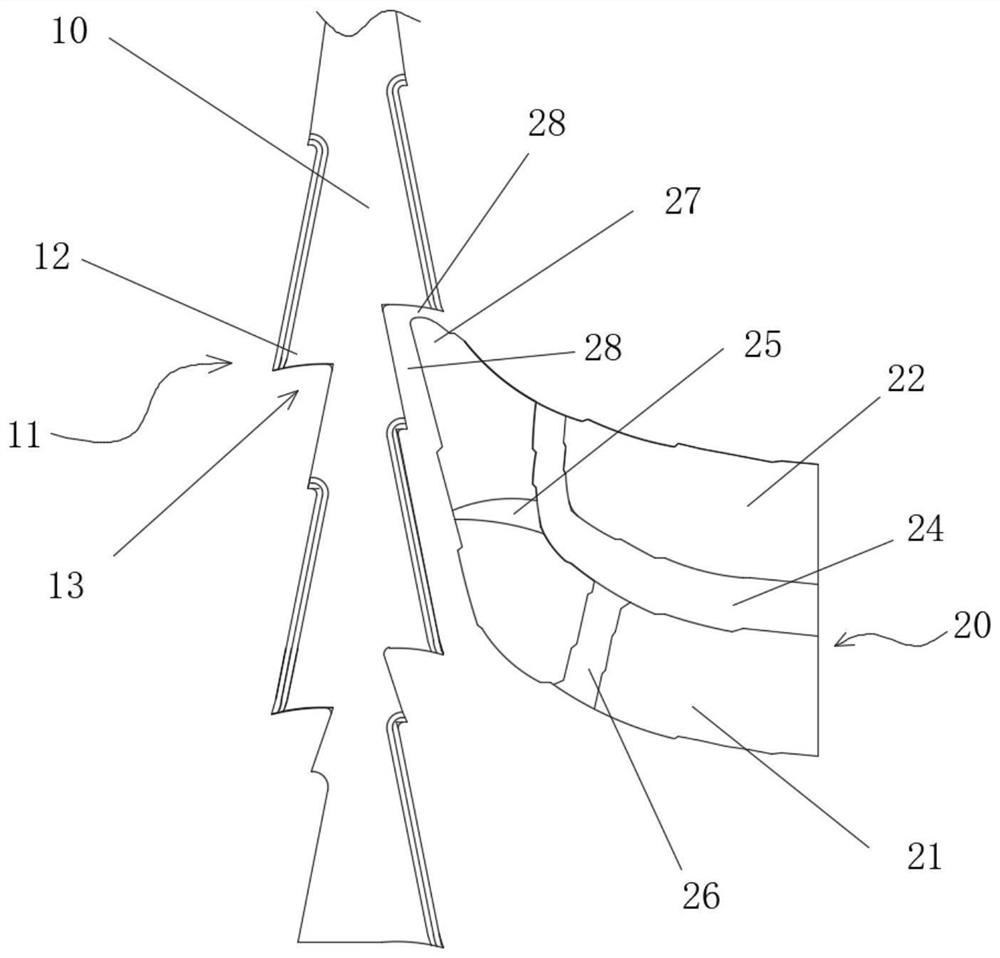

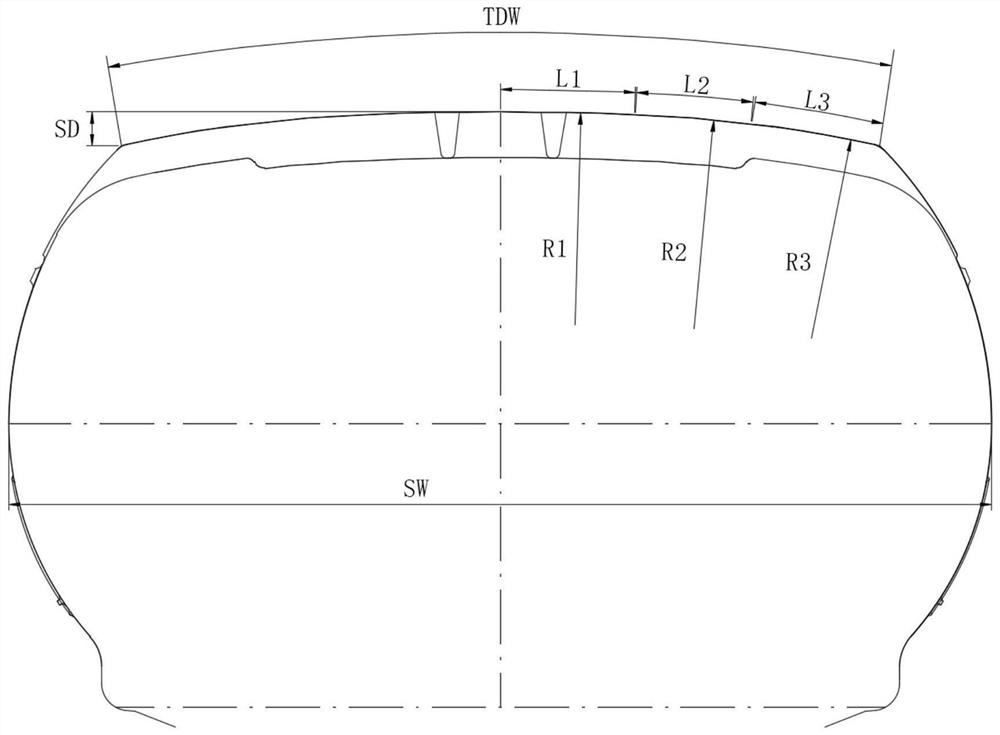

[0025] like Figure 1-2 As shown, a winter tire with zigzag blocks includes a tread 1, a shoulder 2, and a tire pattern disposed on the tread and the shoulder in the tire circumferential direction, the tire pattern including a main tread located in the center of the tread The radial pattern 10 and the blocks located on both sides of the main radial pattern and forming a sliding symmetry with respect to the center line, the block pattern on either side includes a first main groove that is bent and extended from one side of the main radial pattern to the outer side of the tread 30. A curved block 20 is arranged between any two first main grooves, the side of the curved block facing the centerline has a tip 27, and two sides of the main diameter pattern are arranged along the extension direction of the main diameter pattern. zigzag pattern 11; s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com