Single-arm unstacking system

An arm and destacking manipulator technology, which is applied in the destacking of objects, stacking of objects, conveyors, etc., can solve the problem of not meeting the needs of material splitting, save time, reduce labor intensity, and facilitate separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] First of all, the original intention of the design of the present invention is to solve the problem that the existing unstacking system cannot meet the needs of material splitting due to the different weight and size of the split materials, and the existing unstacking system has high requirements for the conveying speed It is difficult to disassemble and convey the materials, and the work efficiency and safety are not high. Therefore, a single-arm unstacking system is designed to efficiently separate the materials. The manual labor intensity is small and it can adapt to the material. The sheet conveying speed is high to split it.

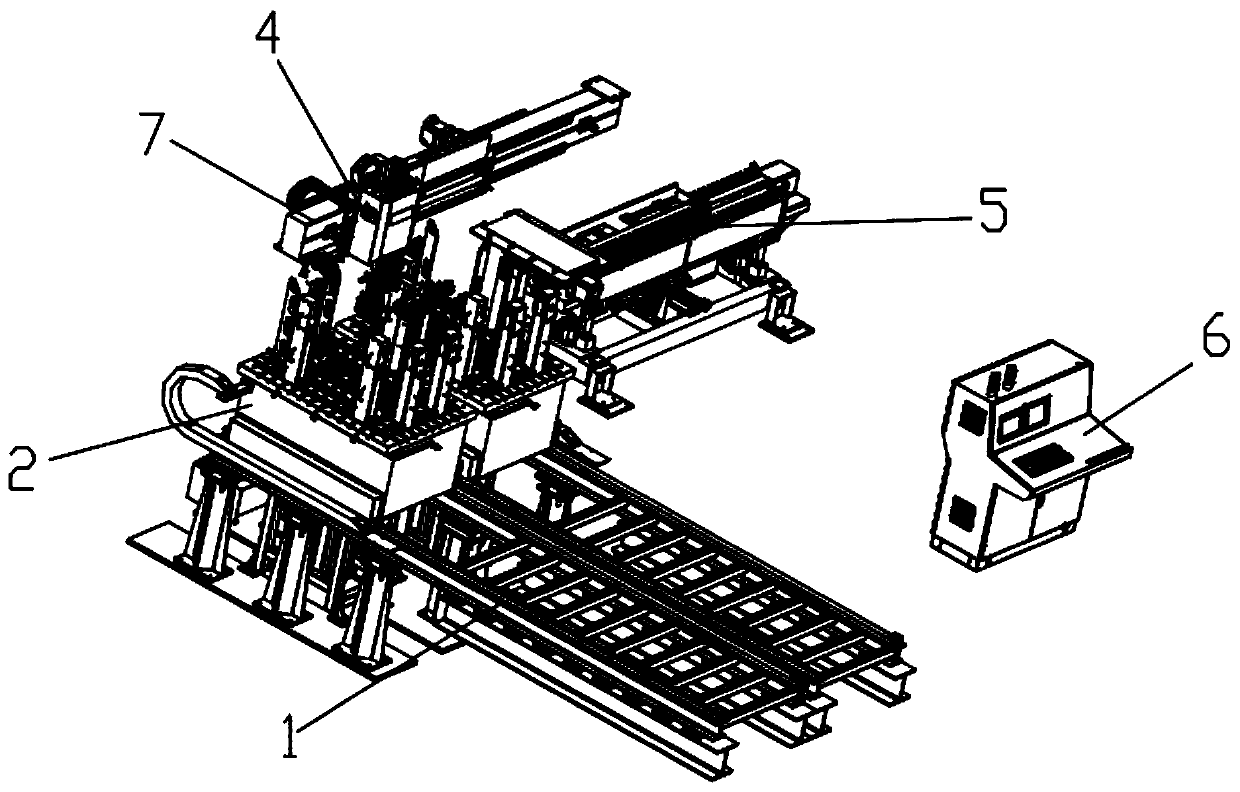

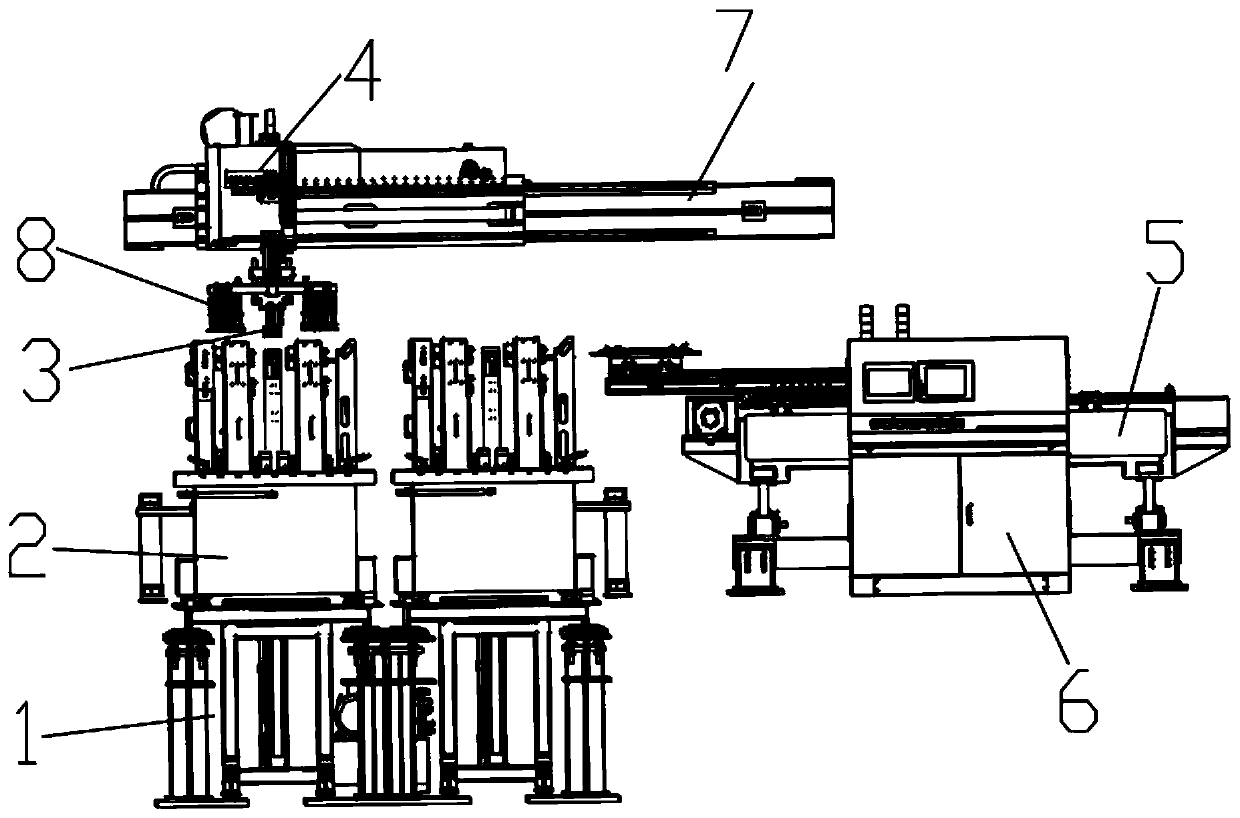

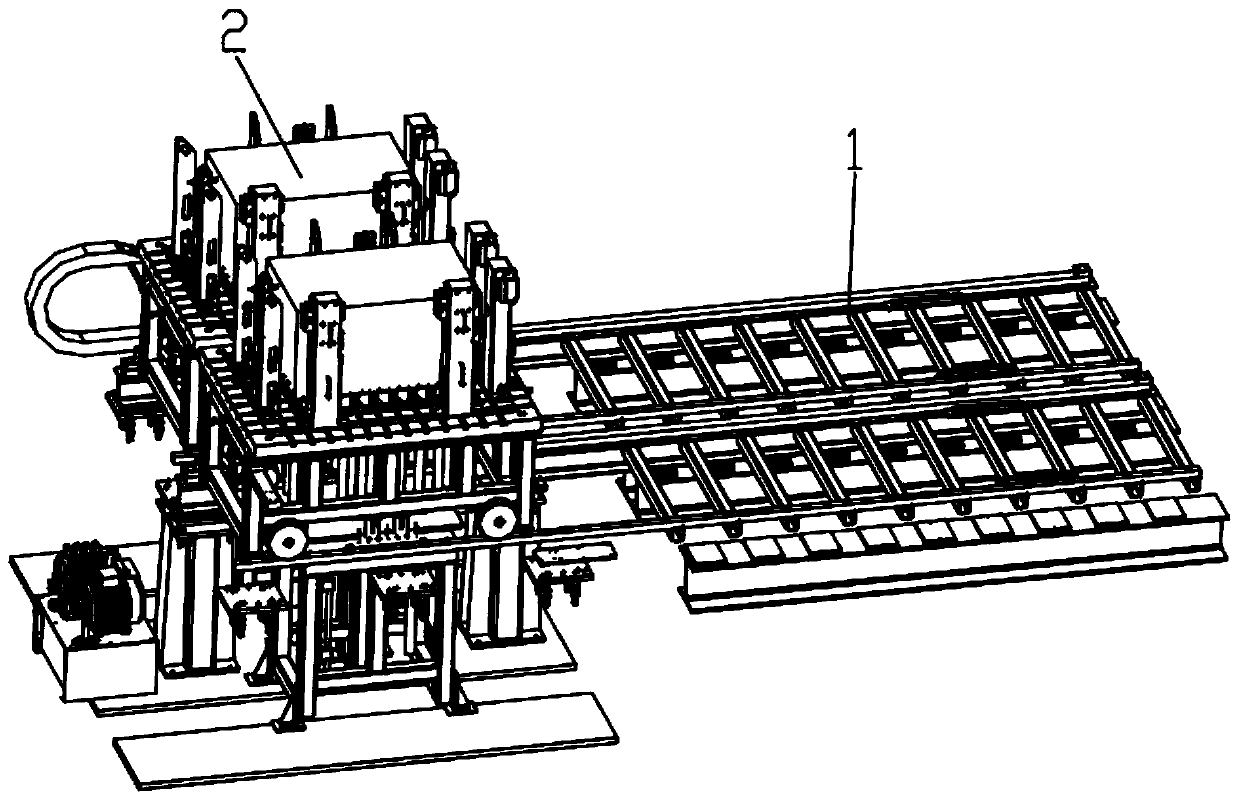

[0020] In order to facilitate those skilled in the art to make this technical solution more clear, the following will be combined with the attached Figure 1-4 Describe the specific structure and principle of each of the above mechanisms: a single-arm unstacking system, including a ground rail 1, a stack splitting trolley 2 arranged above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com