An underwater Viable dry working cabin

A working cabin, dry technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of insufficient underwater operation capacity, backward production efficiency, low operation efficiency, etc., to enhance operation reliability. , easy to operate and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

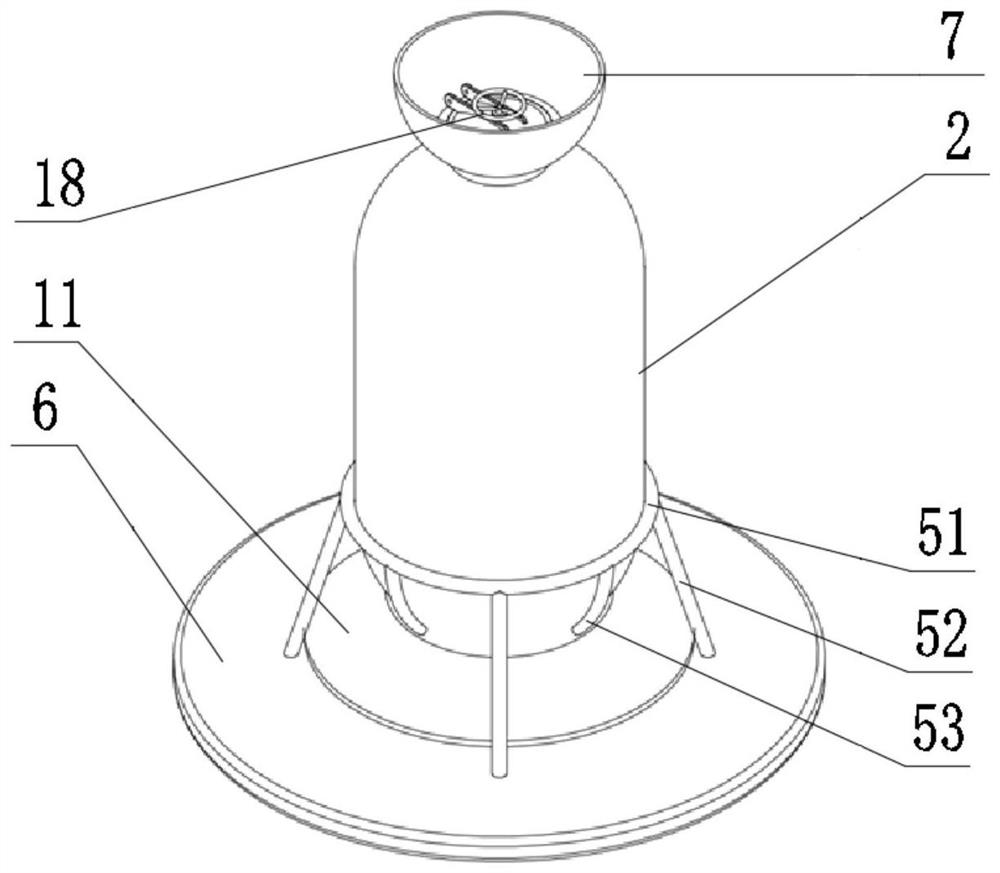

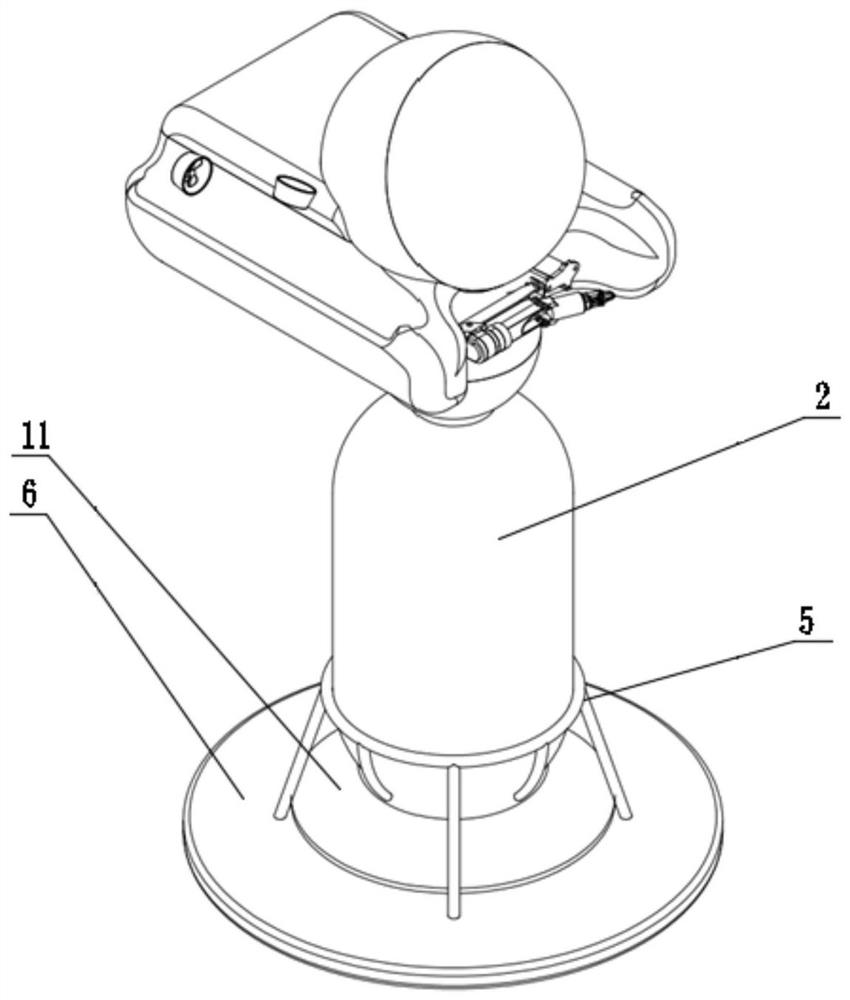

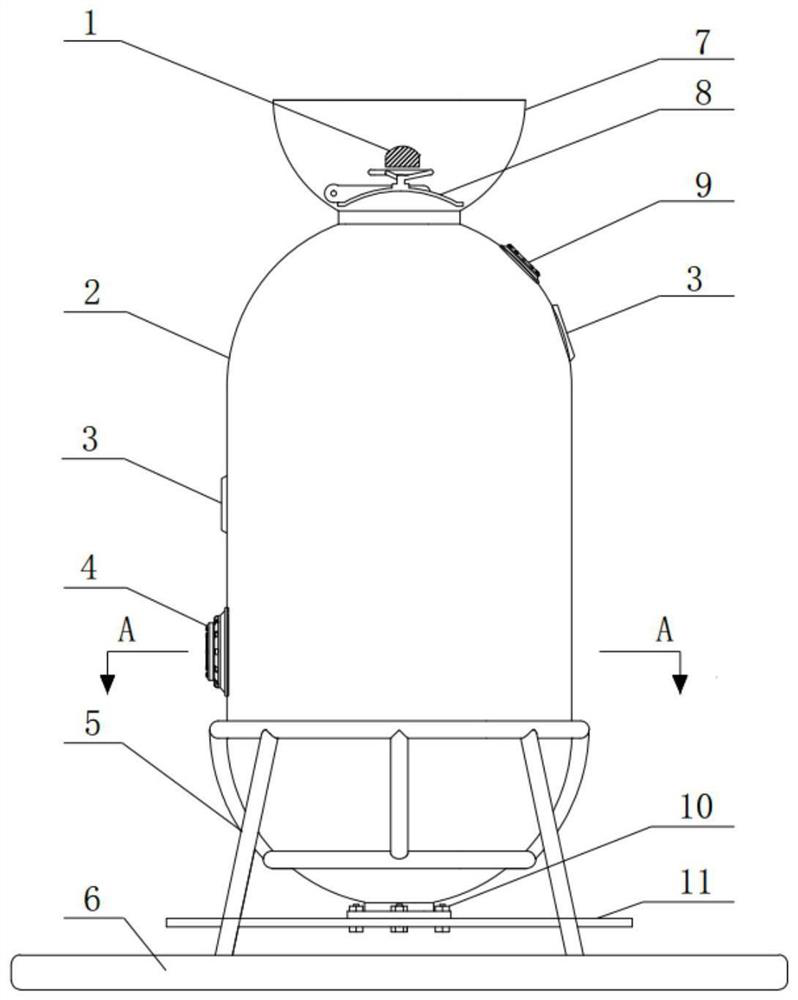

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0026] Such as Figure 3-Figure 7 As shown, the underwater maintainable dry working cabin of this embodiment includes a cabin body 2, which is a cylindrical pressure-resistant cabin with spherical heads at both ends, a docking device 7 is provided at the top hatch, and a bottom The bracket 5 is fixedly installed on the ballast base 6; the connection between the docking device 7 and the cabin body 2 is provided with a two-way opening and closing hatch 8; the bulkhead of the cabin body 2 is provided with an observation window 3, a wet plug interface 9 and production Pipeline interface 4; a deck 12 is provided at the inner bottom of the cabin 2, and an escalator 14 is provided along the bulkhead of the cabin 2 from the deck 12 to the two-way opening and closing hatch 8; a control cabinet 13 is provided on the deck 12, and the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com