Manifold system capable of realizing low-pressure suction and high-pressure discharge

A technology of manifold system and low-pressure manifold, which is applied in the field of plunger pump fracturing, can solve the problems of unsmooth discharge of five-cylinder plunger pump liquid and sand accumulation in low-pressure manifold, so as to achieve smooth discharge, avoid sand accumulation, and guarantee The effect of large displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

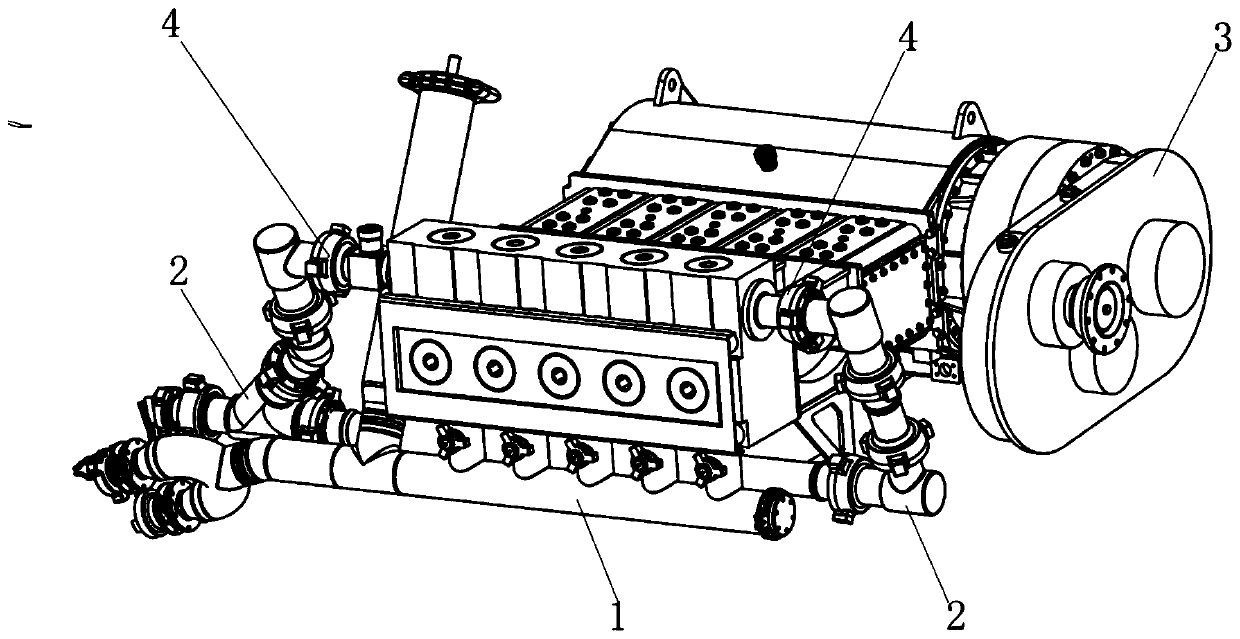

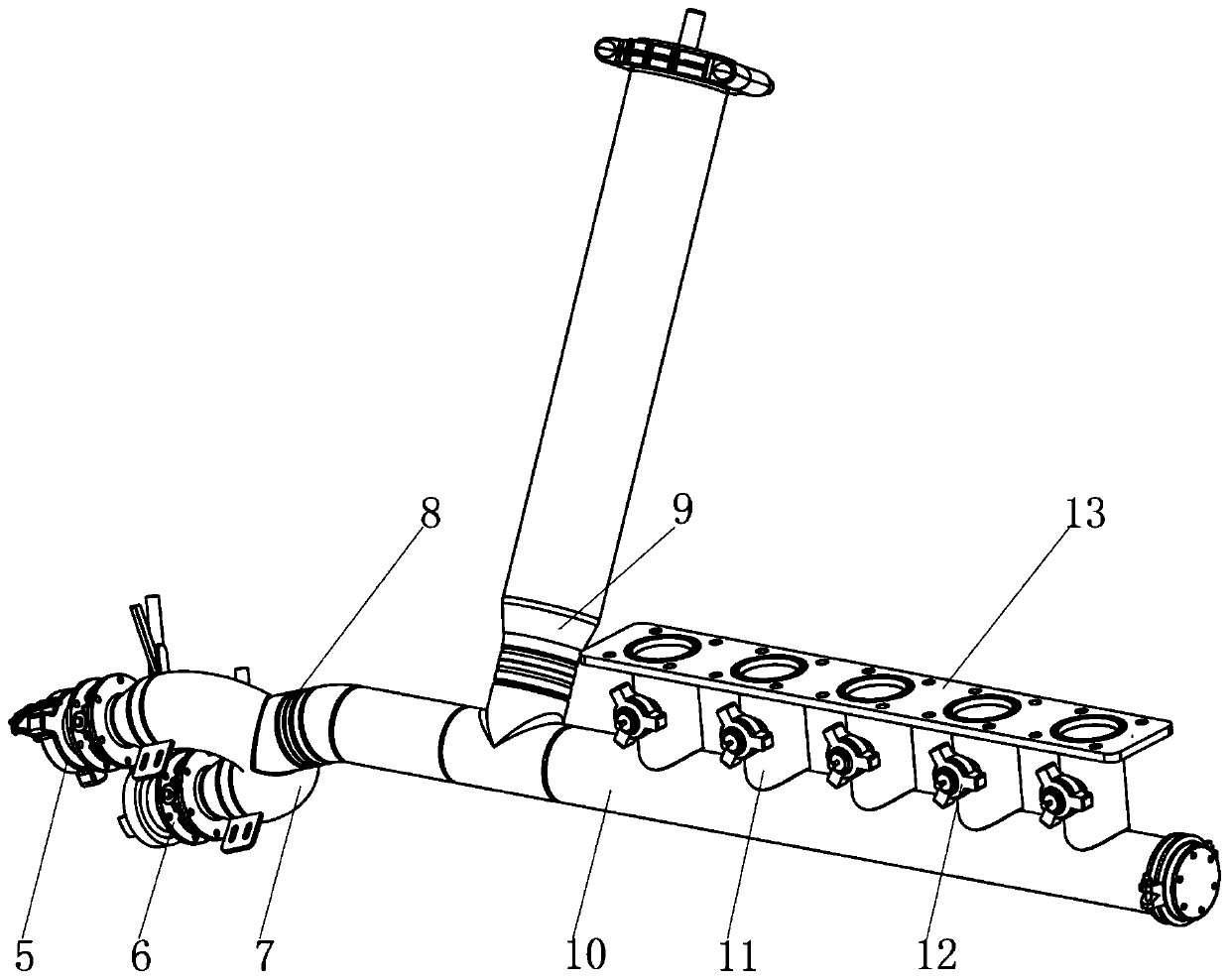

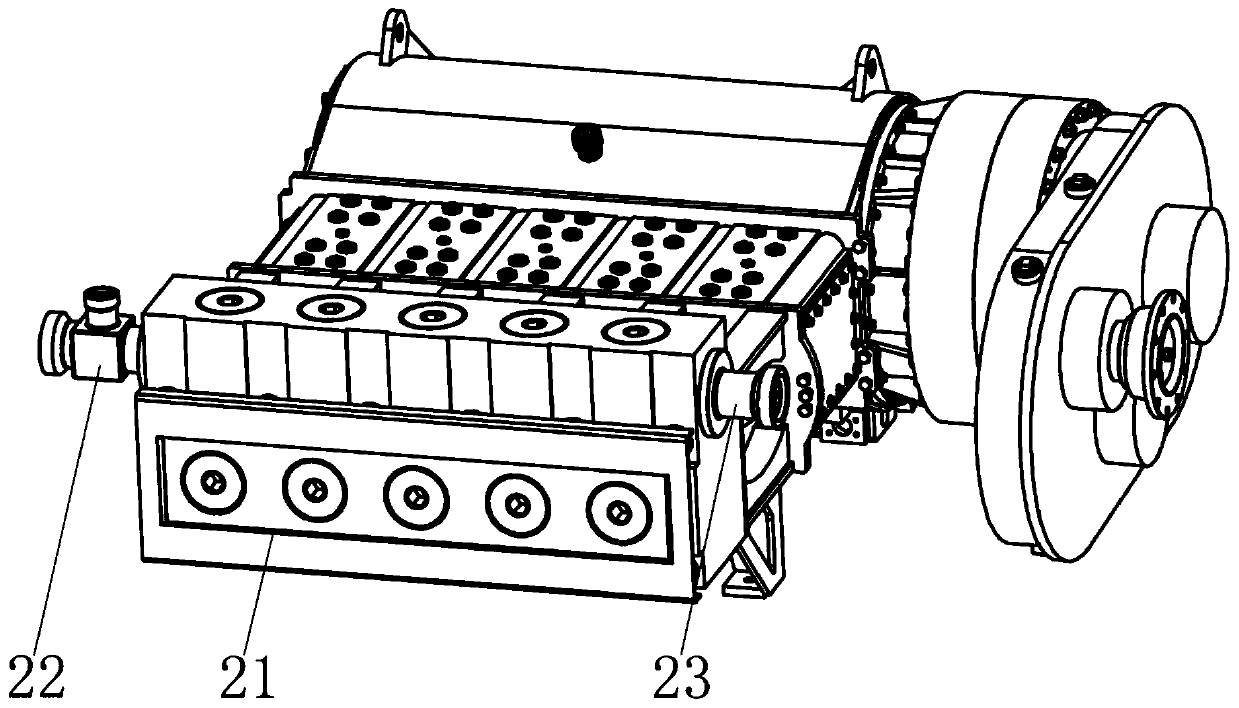

[0028] Such as Figures 1 to 5 As shown, a manifold system for low-pressure suction and high-pressure discharge includes a low-pressure manifold 1, a high-pressure manifold 2, and a plunger pump 3. The low-pressure manifold 1 is the input medium for the hydraulic end 21 of the plunger pump 3. The hydraulic end 21 of the plunger pump 3 is provided with a discharge port 4, and there are 2 discharge ports 4, and the 2 discharge ports 4 are connected to the high-pressure manifold 2. The double discharge form of the five-cylinder plunger pump realizes the smooth discharge of liquid from the five-cylinder plunger pump, avoids sand accumulation inside the low-pressure manifold 1, and at the same time ensures the large displacement of the fracturing equipment.

[0029] The plunger pump 3 is a five-cylinder plunger pump. The power of the plunger pump 3 is above 5000HP. The five-cylinder plunger pump above 5000HP guarantees the high-pressure and large-displacement power source of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com