Extrusion type eccentric rotor pump and use method thereof

An eccentric rotor, extrusion technology, used in rotary piston pumps, rotary piston/oscillating piston pump components, pumps, etc., can solve problems such as poor self-priming capacity of vane pumps, and achieve easy maintenance and small size. , the effect of large displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

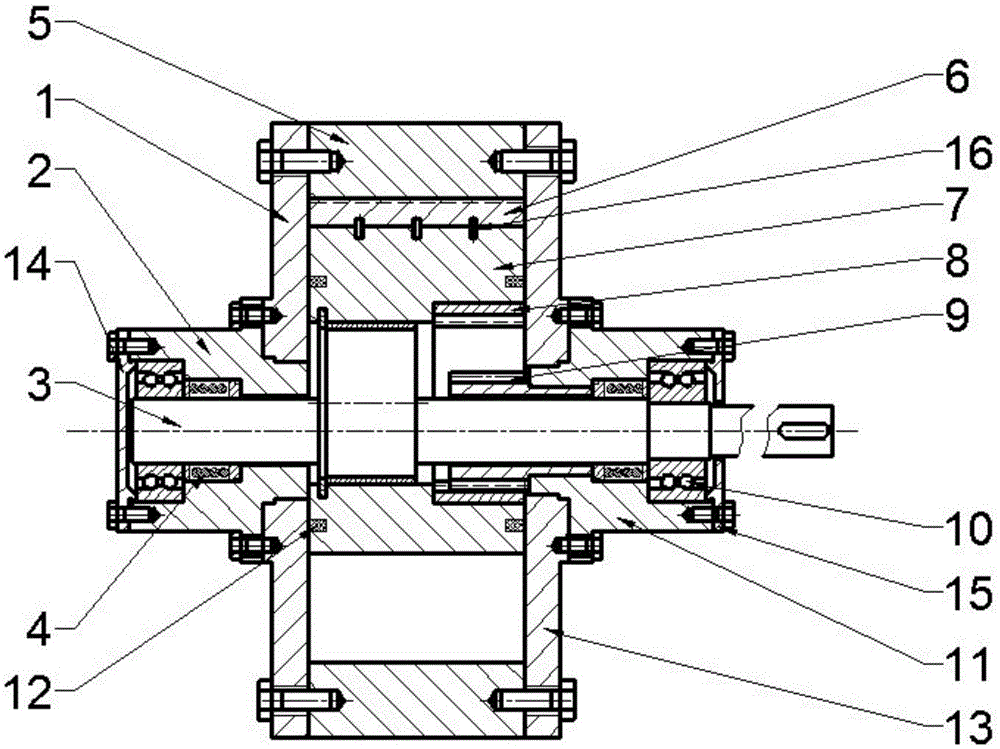

[0042] like figure 1 , Extrusion type eccentric rotor water pump is composed of rotor 7, side wall 5, front cover 1 and rear cover 13, input shaft 3, inner ring gear 8, fixed gear 9, spring seal 6, wear-resistant seal ring 12, It is composed of mechanical seal 4, double row angular contact bearing 10 and so on. The rotor 7 of the extruded eccentric rotor water pump cooperates with the eccentric block of the input shaft 3 through the shaft sleeve; the input end of the input shaft 3 is assembled with the end cover through the double row angular contact ball bearing and the small end cover, and the front end cover 11 is passed through The fastening bolt is fixed with the front cover 13; the other end of the input shaft 3 is assembled with the rear end cover 11 through the double row angular contact ball bearing 10 and the rear small end cover 14, and the rear end cover 2 is connected with the rear cover through the fastening bolt. Cover 1 is fixed. The reliability of the seal ...

Embodiment 2

[0052] The difference between this embodiment and implementation 1 is:

[0053] Inside the rotor there are teeth that cooperate with the fixed gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com