Lock nut assembly and method for assembling lock nut assembly

A technology for locking nuts and components, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve problems such as high frequency of occurrence, failure of spindle bearings, damage to the spindle system, etc., and achieve a good anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

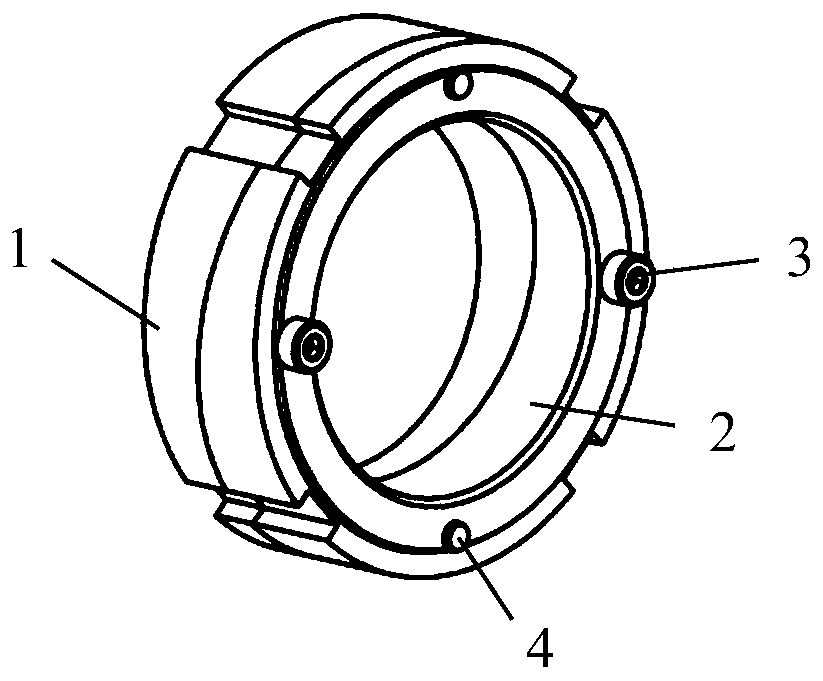

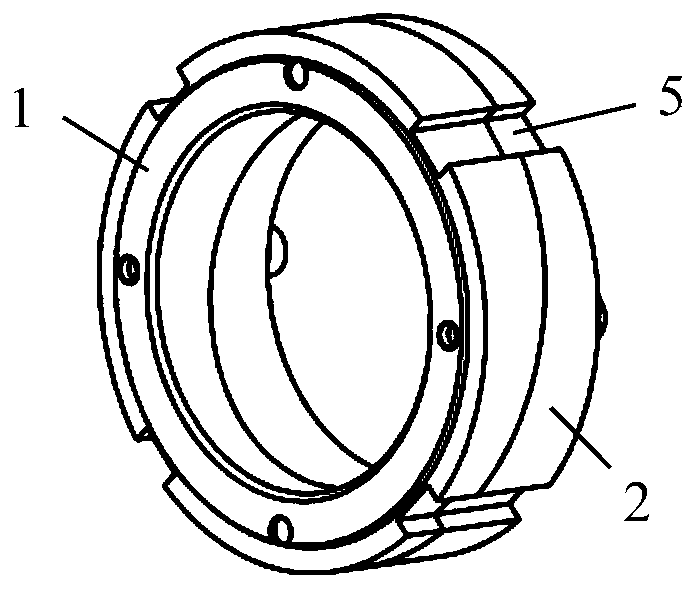

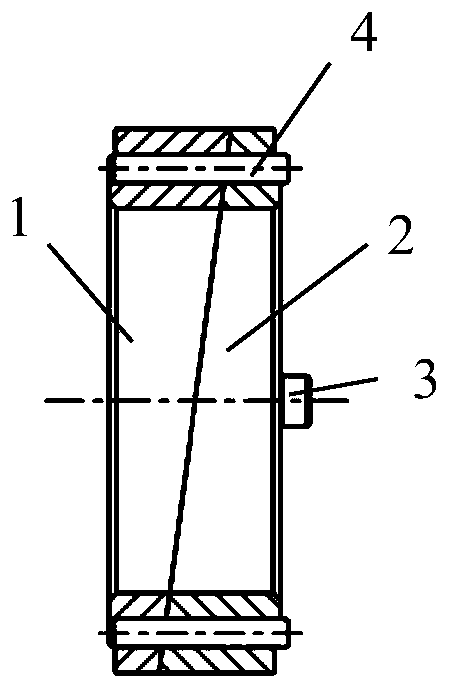

[0029] figure 1 A side view of a cage nut assembly according to a preferred embodiment of the present invention is shown. The lock nut assembly includes two lock nuts that fit together in the axial direction, that is, a first lock nut 1 and a second lock nut 2 . The first lock nut 1 and the second lock nut 2 together form a substantially circular lock nut assembly. Such as figure 1 As shown, the first lock nut 1 and the second lock nut 2 have the same shape, and both are non-rotationally symmetrical structures. The first lock nut 1 and the second lock nut 2 have coaxial central holes with the same diameter, and internal threads (not shown) are all provided in each central hole, and the internal thread of the central through hole of the lock nut assembly is Consistent and continuous. exist figure 1 The axial end face of the second lock nut 2 can be clearly seen in . figure 2 shows the basis figure 1 A side view of the union nut from another angle, namely showing the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com