Portable building coating stirring device

A technology of architectural coatings and stirring devices, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., which can solve the problems of laborious mixing and achieve the effect of easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

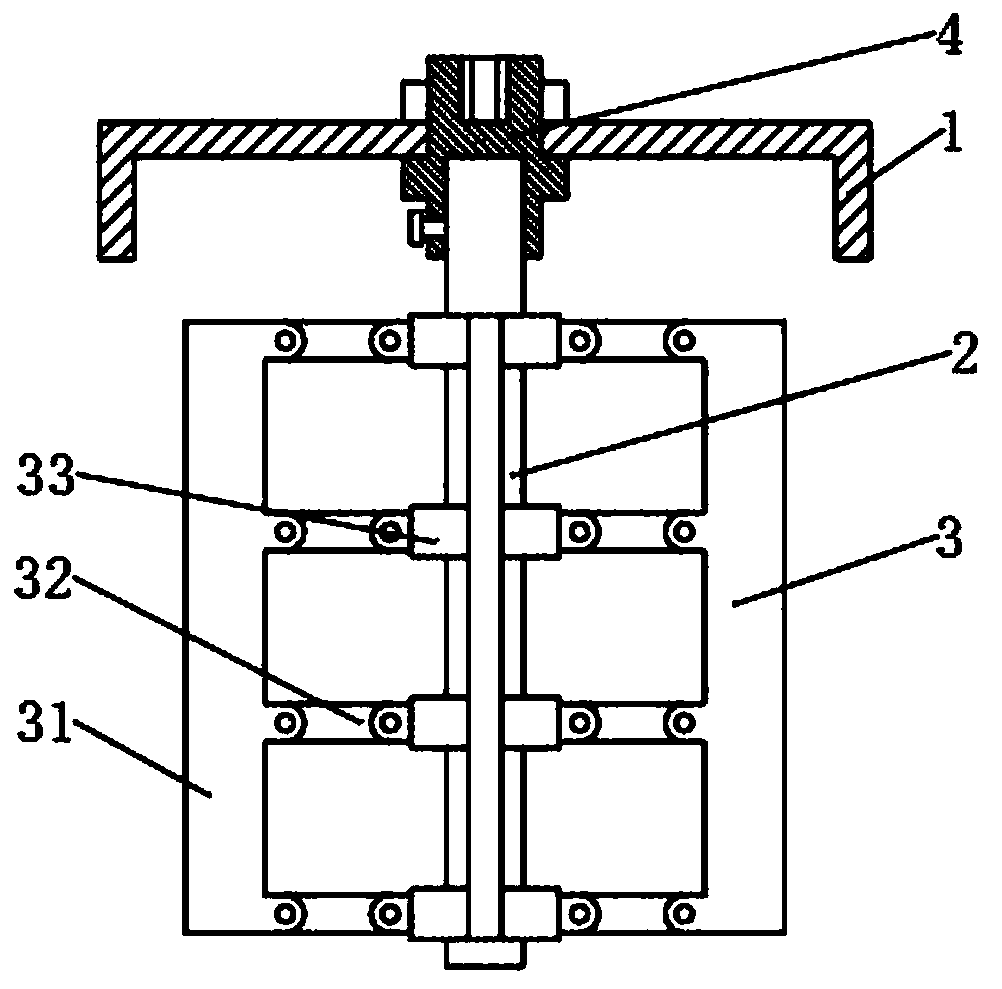

[0023] Depend on Figure 1-Figure 3 As shown, a portable building paint mixing device includes a fixed cover 1, a stirring shaft 2 is installed on the fixed cover 1, and the stirring shaft 2 can rotate around its own axis on the fixed cover 1, and the stirring shaft 2 is installed to the On the fixed cover 1, and the stirring shaft 2 can be disassembled from the connecting shaft 4, and the connecting shaft 4 can rotate around its own axis. A stirring blade 3 for stirring, the stirring blade 3 can be folded when not in use;

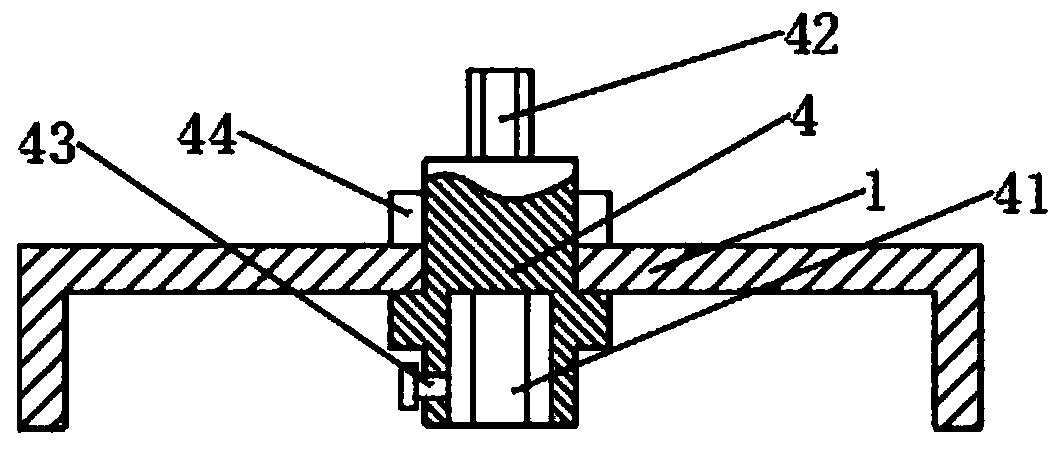

[0024] The fixed cover 1 is a bucket cover structure in the prior art, and the middle of the fixed cover 1 is provided with a through hole for installing the connecting shaft 4, such as Figure 4 As shown, the connecting shaft 4 is a circular shaft shape, and the drilling machine connecting shaft 42 is arranged on the upper end of the stirring shaft fixing hole 41. The stirring shaft fixing hole 41 of the shaft 2, the stirring shaft fixing hole 41 is a h...

Embodiment 2

[0028] Depend on Figure 1-Figure 3 As shown, a portable building paint mixing device includes a fixed cover 1, a stirring shaft 2 is installed on the fixed cover 1, and the stirring shaft 2 can rotate around its own axis on the fixed cover 1, and the stirring shaft 2 is installed to the On the fixed cover 1, and the stirring shaft 2 can be disassembled from the connecting shaft 4, and the connecting shaft 4 can rotate around its own axis. A stirring blade 3 for stirring, the stirring blade 3 can be folded when not in use;

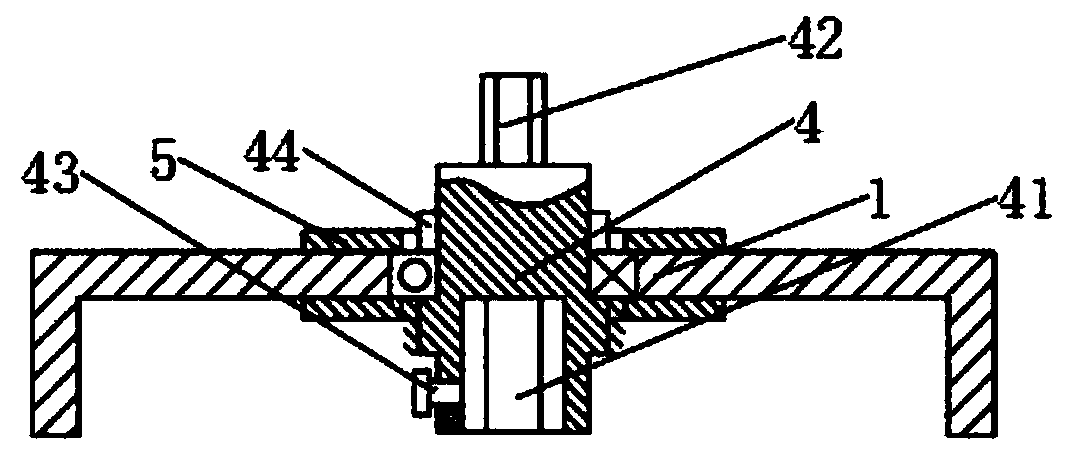

[0029] In this embodiment, the connecting shaft 4 is fixed to the fixed cover 1 through bearings, and the inner and outer sides of the fixed cover 1 are also provided with bearing limit rings 5, and the bearing limit rings 5 are fixed to the fixed cover 1 by screws to prevent the bearings from Fall off from the fixed cover 1, and the bearing limit ring 5 is circular;

[0030] Other structures in this embodiment are the same as those in Embodiment 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com