Air-pressure-controllable flexible grinding and polishing system

An air pressure control, grinding and polishing technology, applied in grinding/polishing equipment, grinding machines, optical surface grinding machines, etc., can solve the problems of low efficiency, difficult processing of deep cavity special-shaped optical components, low processing accuracy, etc., to avoid trachea entanglement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

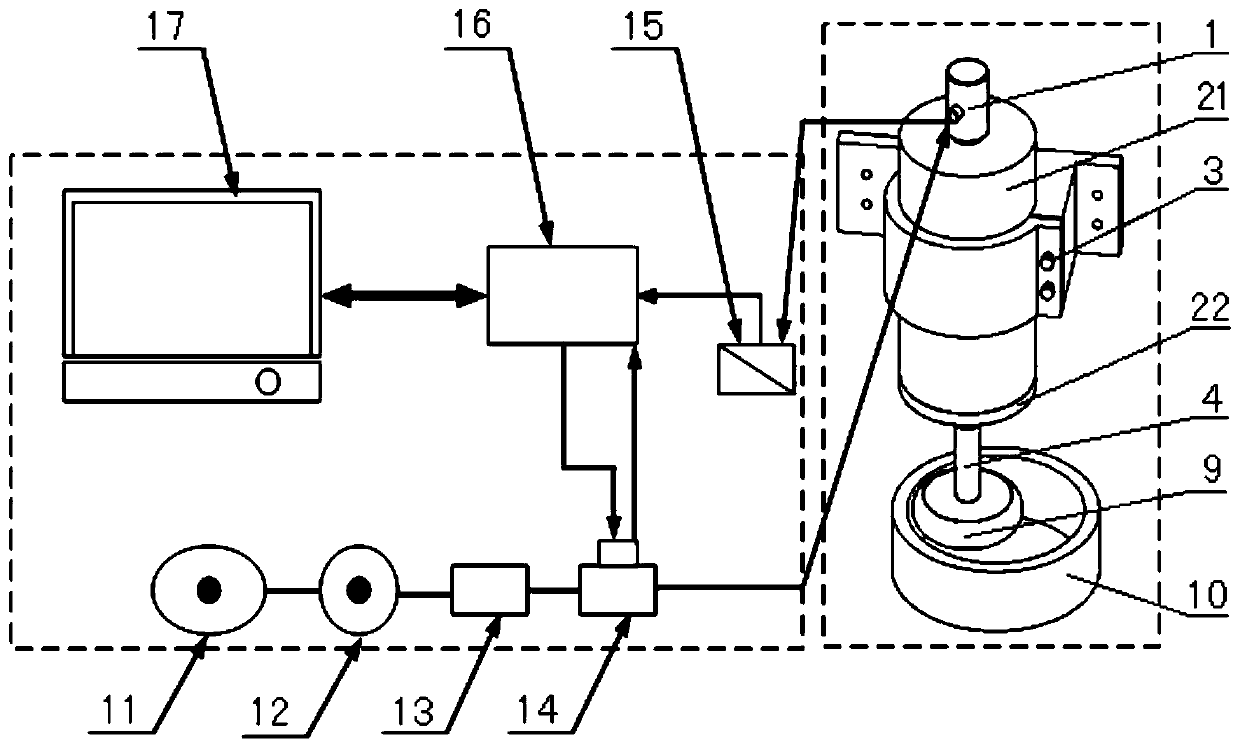

[0032] Such as figure 1 As shown, the air pressure controllable flexible grinding and polishing system proposed by the present invention includes a grinding and polishing tool and an air pressure control device.

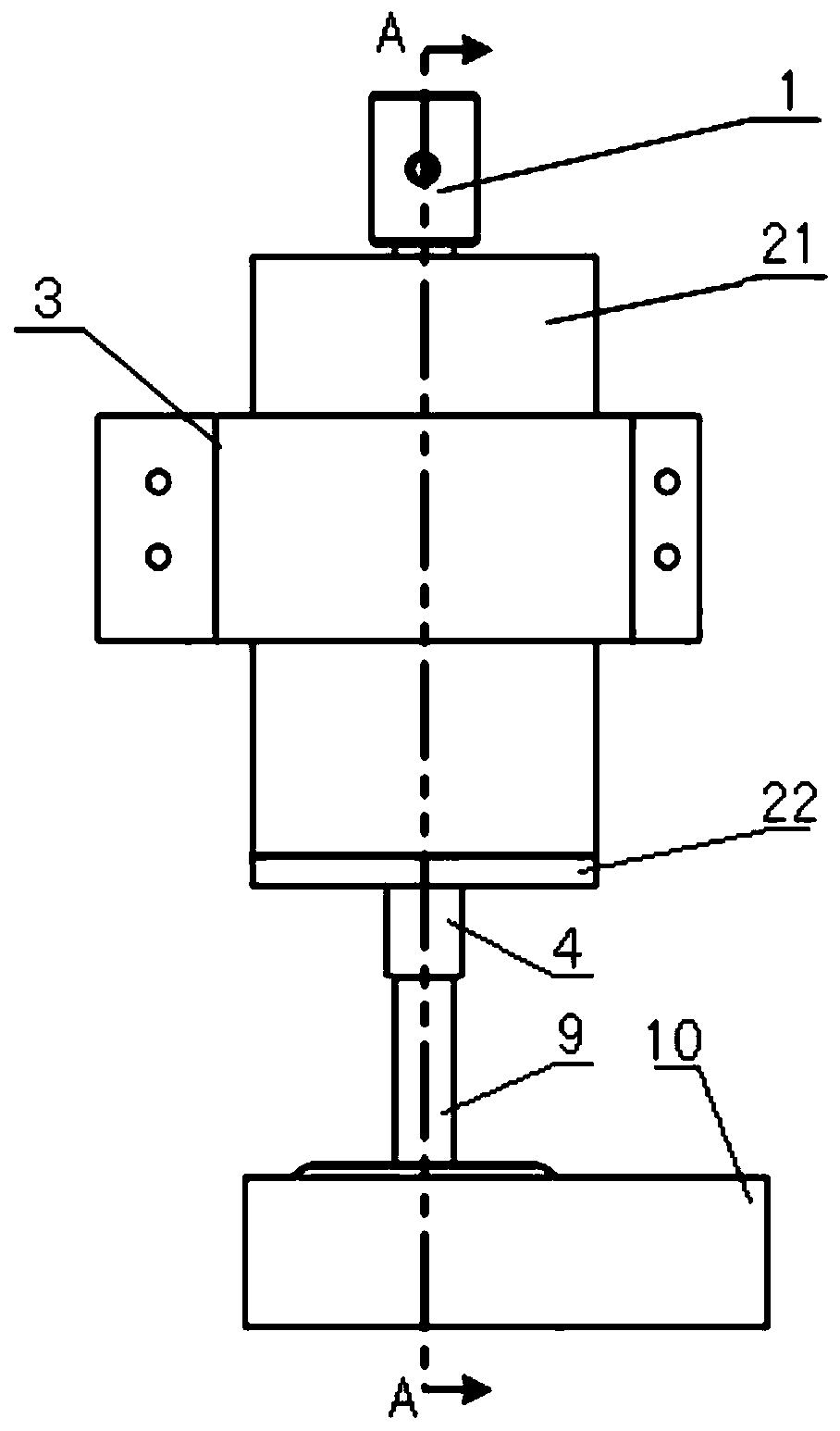

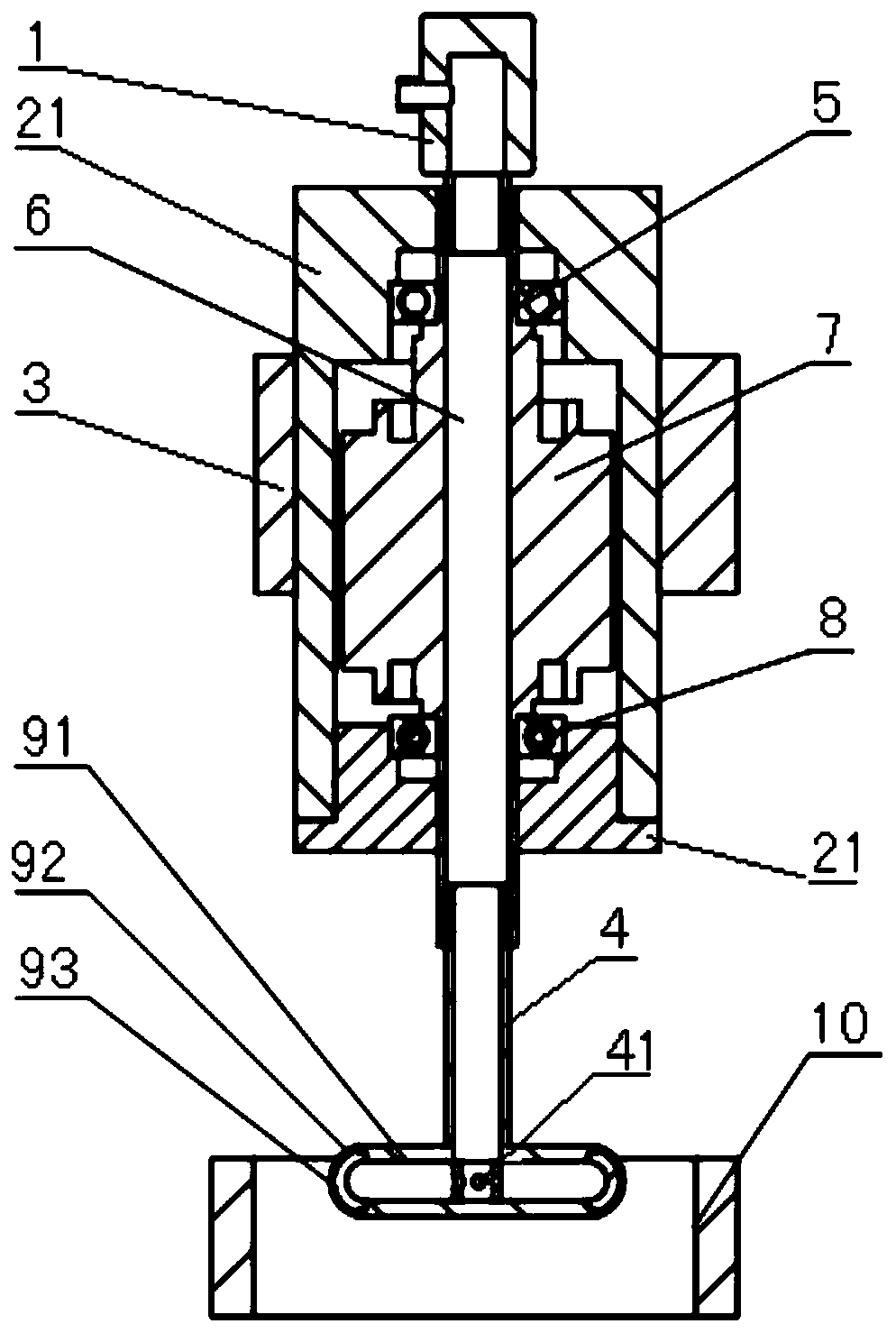

[0033] The grinding and polishing tool is a wheeled airbag grinding and polishing tool, such as figure 2 with image 3 As shown, the wheel airbag grinding and polishing tool includes a housing, the housing includes a main shaft housing 21 and a bottom end cover 22, the main shaft housing 21 is provided with a hollow motor 7, and a hollow motor 7 passes through a Hollow rotating main shaft 6, said hollow rotating main shaft 6 rotates relative to said housing, that is, an upper rolling bearing 5 is provided between said hollow rotating main shaft 6 and the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com