Design and manufacturing method for dentition undercut solid retention tooth preparation guide plate

A production method and retention technology, which are applied in the directions of processing and manufacturing, manufacturing auxiliary devices, and processing data acquisition/processing, etc., can solve the problems of difficult operation, multiplication of errors, and unfavorable promotion and use by grassroots medical personnel, and are conducive to popularization, application and improvement. Retention strength, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

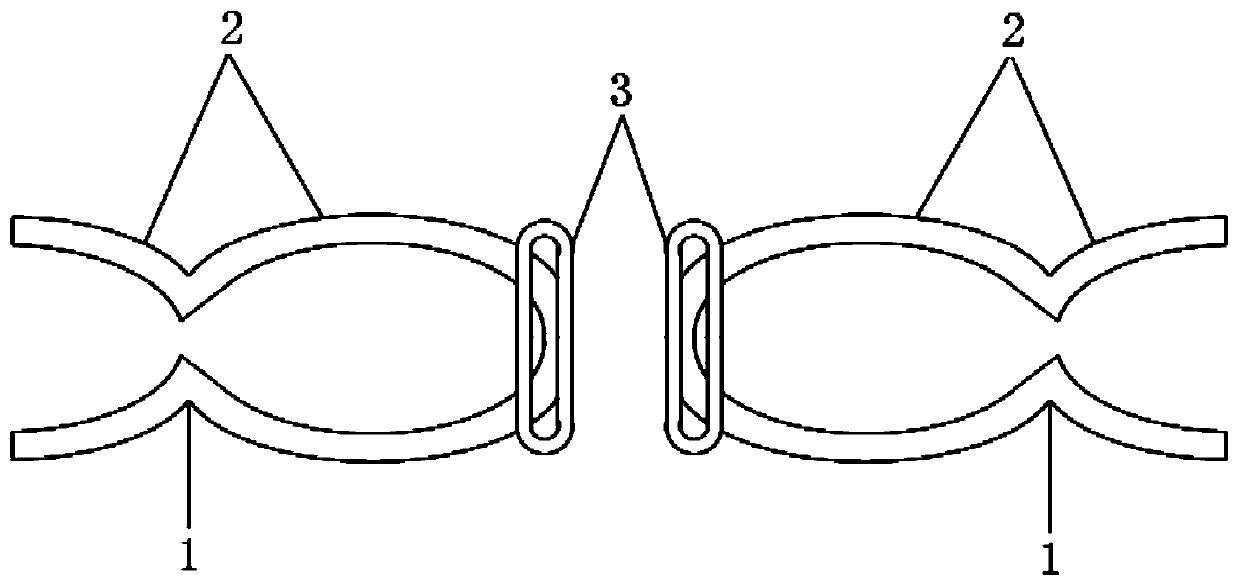

[0018] see figure 1 , a method for designing and manufacturing a dentition undercut strong retention tooth preparation guide plate of the present invention has the following steps:

[0019] (1) Three-dimensional scanning of teeth and adjacent teeth that require tooth preparation;

[0020] (2) Design the three-dimensional shape of the tooth preparation with three-dimensional reverse engineering software;

[0021] (3) According to the three-dimensional shape of the tooth preparation in step (2), design a guide groove on the guide plate that can guide the movement path of the dental bur throughout the entire process;

[0022] (4) Offset the entire surface of the gingiva and crown near the edge of the tooth by 1 mm, including the undercut area, as the retaining part of the guide plate;

[0023] (5) The guide groove and the retaining par...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap