Single-screw conveyor

A conveyor and single-screw technology, applied in the field of single-screw conveyors, can solve the problems of damaging the power source motor, affecting the rotation of the rotating shaft, drying up and sticking, etc., and achieve the effects of prolonging the service life, preventing the rotation from being blocked, and eliminating the blocking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

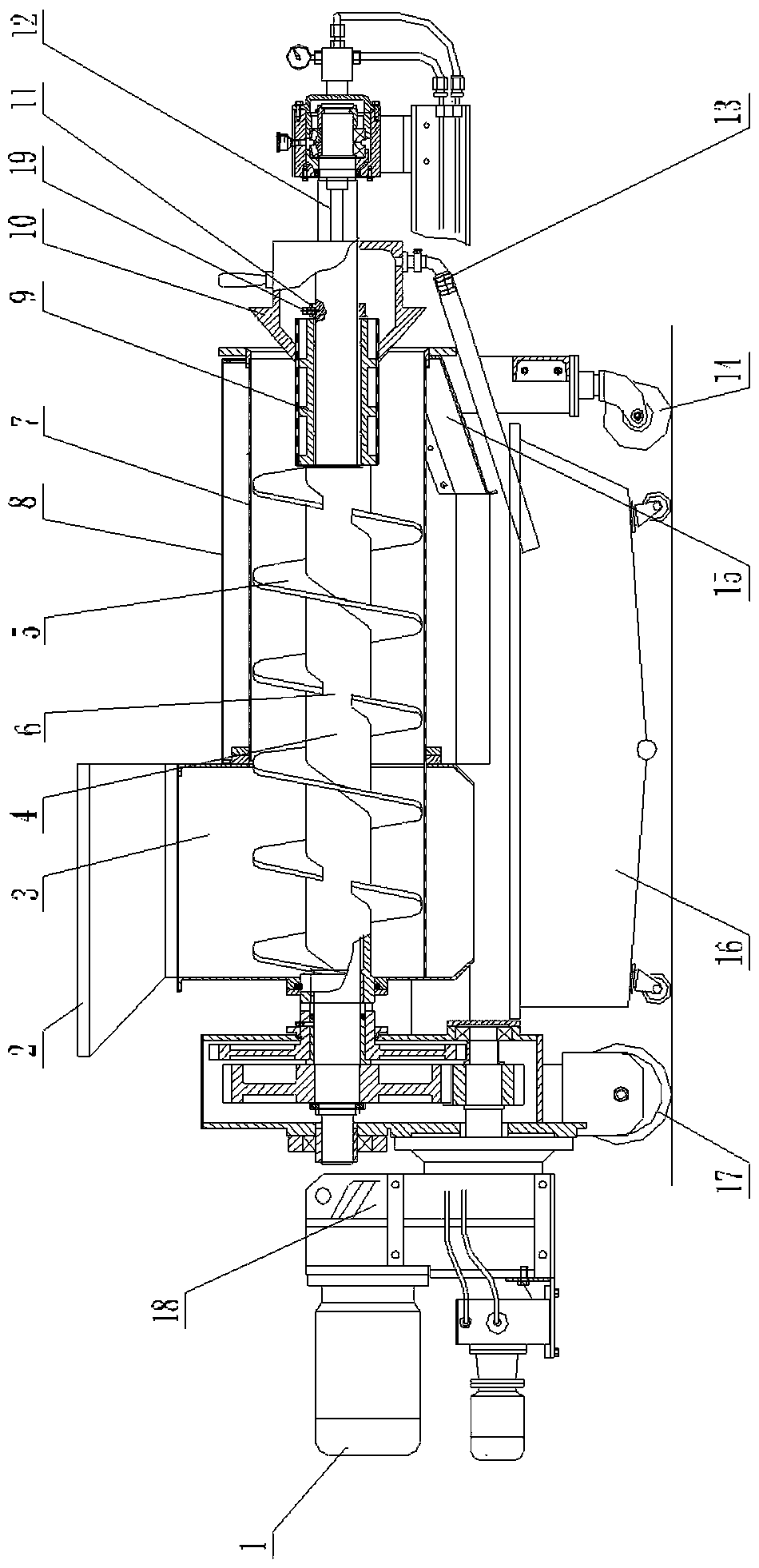

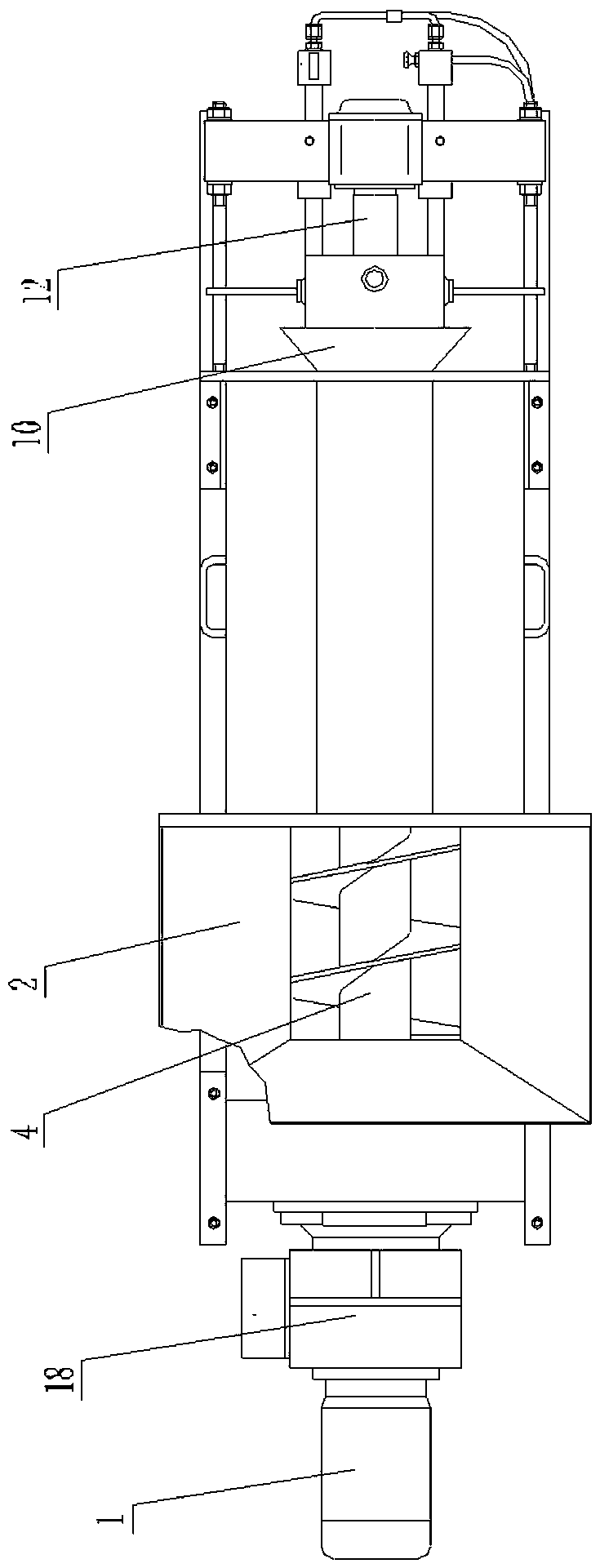

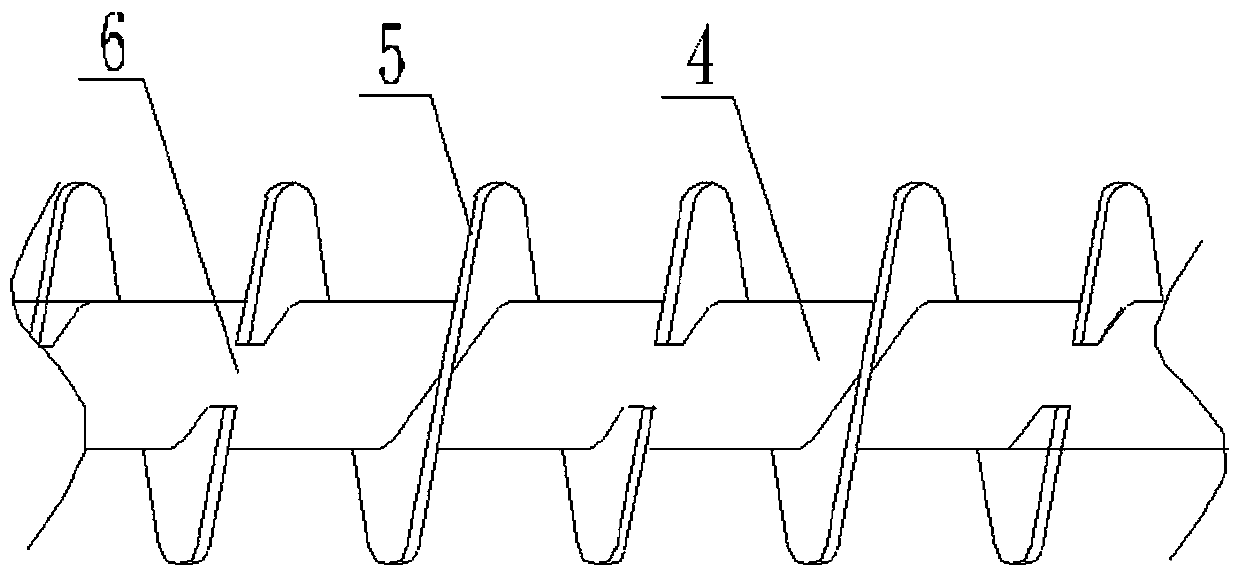

[0021] like Figure 1-3 As shown, a single screw conveyor includes a bracket on which a feeding box 3 with an open top is installed, and a feeding hopper 2 is installed on the top of the feeding box 3 . The right side of feed box 3 is installed along the horizontal direction the sieve cylinder 7 that is communicated with feed box 3, and sieve cylinder cover 8 is installed on the outside of sieve cylinder 7. The inside of feeding box 3 and sieve cylinder 7 is horizontally installed through the rotating shaft 12 of feeding box 3 and sieve cylinder 7, and the left end of rotating shaft 12 is installed the driving mechanism that is used to drive rotating shaft 12 to rotate, and driving mechanism comprises motor 1, and motor 1 connected reduction box, the left end of rotating shaft 12 is connected with reduction box. The screw conveying mechanism that is set on the rotating shaft 12 and rotates coaxially with the rotating shaft 12 and is used for conveying materials, the screw con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com