A kind of backing plate under composite sleeper and sleeper thereof

A technology for a sleeper and a backing plate, applied in the field of rail transit, can solve the problem of not involving the connection between the backing plate under the sleeper and the sleeper, and achieve the effects of reducing construction cost, reducing construction difficulty and improving installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

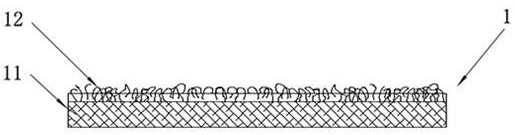

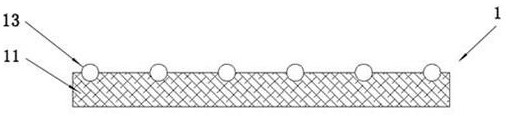

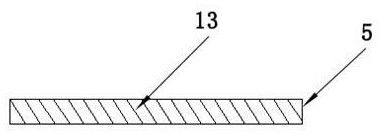

[0029] Such as figure 1 and figure 2 Shown: a backing plate 1 for a composite sleeper, comprising an upper part and a lower part, the upper part is a connection layer connected with the sleeper, the lower part is a vibration-damping layer 11, and the connection layer and the vibration-damping layer 11 One-piece molding by vulcanization. When installing the under-pillow pad, various cumbersome processes such as gluing, drying, and bundling are no longer required, which reduces costs and improves production efficiency.

[0030] The connecting layer is a combination of various fiber filaments or various metal filaments, or a combination of various fiber filaments and various metal filaments. The fiber filament is any one or a combination of several of nylon fiber, polyester fiber and other polymer fibers, and the fiber filament has strong corros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com