Device and method for measuring dynamic heat conductivity coefficient in silver nanoparticle conductive ink sintering process

A silver nanoparticle, conductive ink technology, applied in the direction of material thermal development, material resistance, etc., can solve problems such as errors, and achieve the effect of accurate sintering temperature control, wide promotion significance, and improved consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the invention is not limited to the following examples.

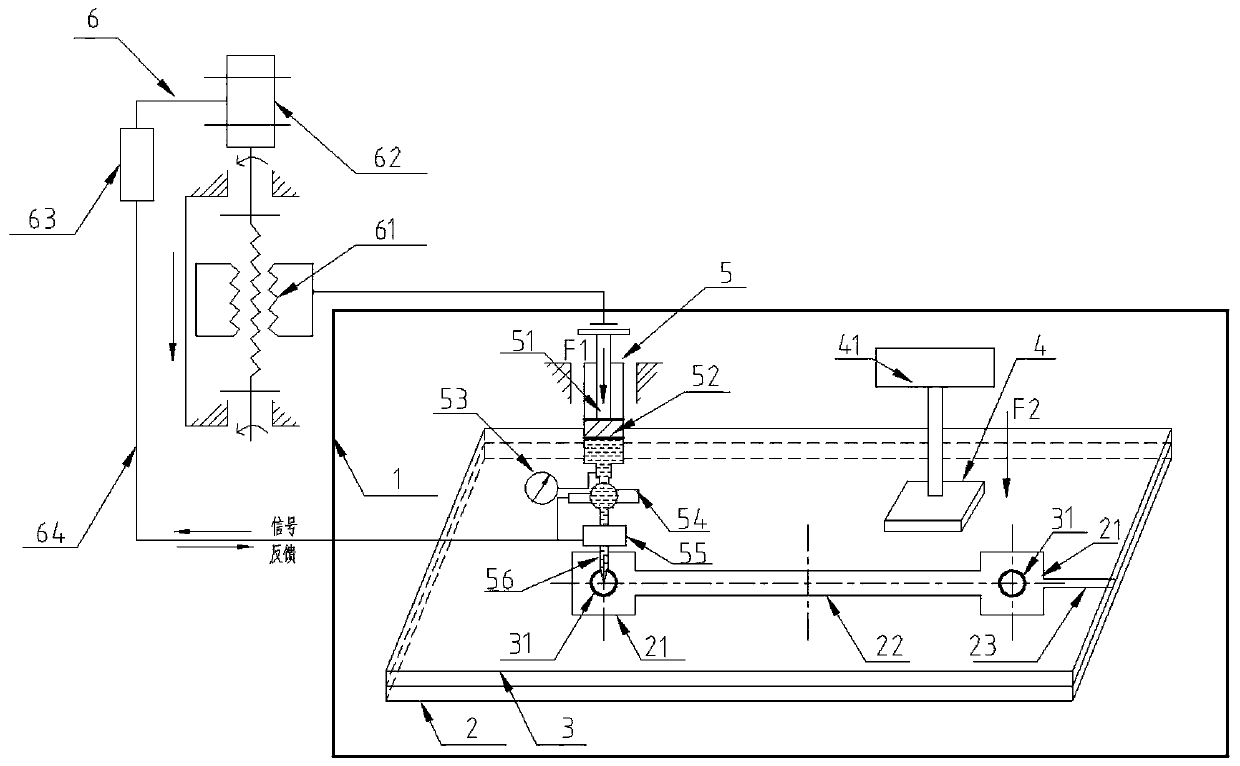

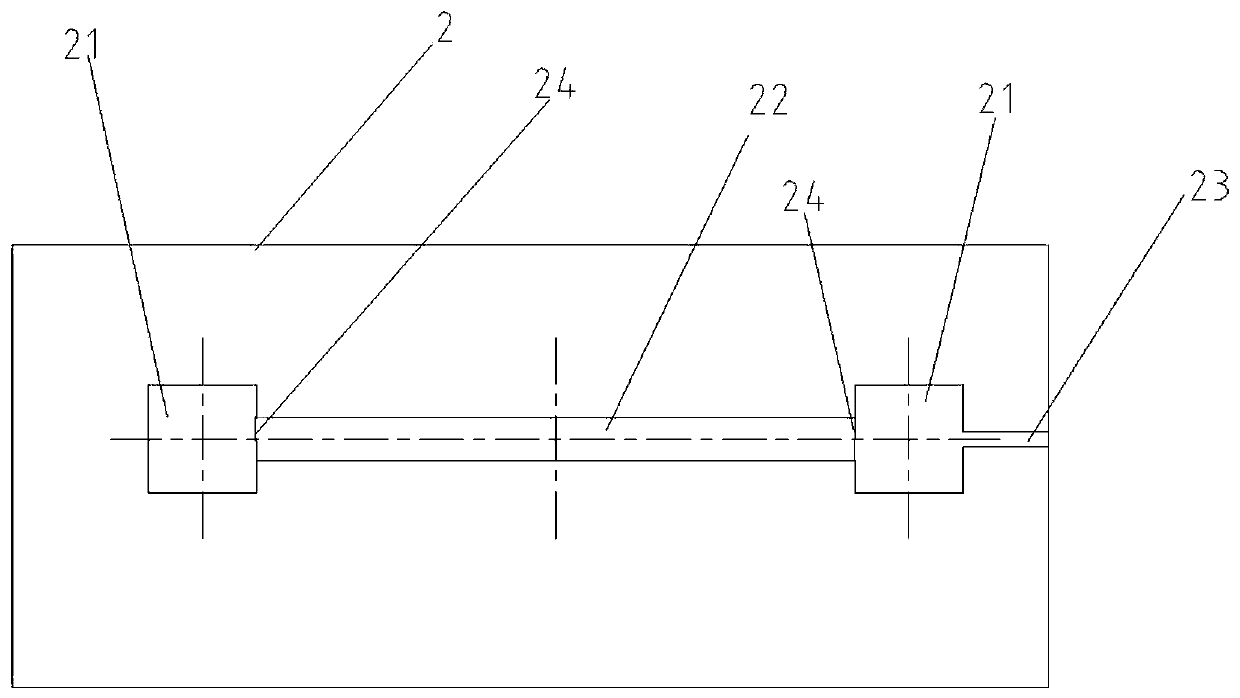

[0045] see Figure 1 to Figure 2 As shown, the dynamic thermal conductivity measurement device for silver nanoparticle conductive ink sintering process includes a precise temperature control heating platform 1, a substrate 2, a cover substrate 3, a pressure plate 4, a syringe pump assembly 5, and a power control system 6; the substrate 2 is fixed on a precisely controlled The top of the warm heating platform 1; the substrate 2 has a microcavity; the microcavity includes two square electrode grooves 21, an injection wire groove 22 and an exhaust groove 23; the square electrode grooves 21 are connected through the injection wire groove 22, wherein One side of a square electrode groove 21 communicates with the exhaust groove 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com