Coal-pillar-free self-roadway-forming automatic mining model test device and method

A model test device, a technology without coal pillars, which is used in measurement devices, earthwork drilling, soil material testing, etc. multipurpose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

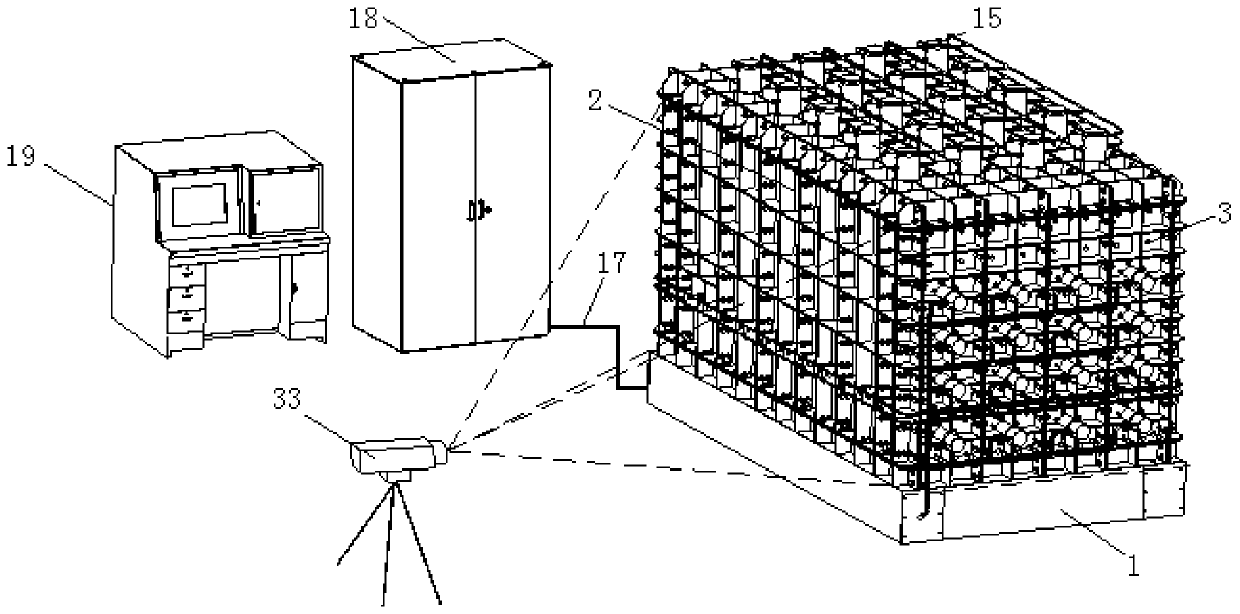

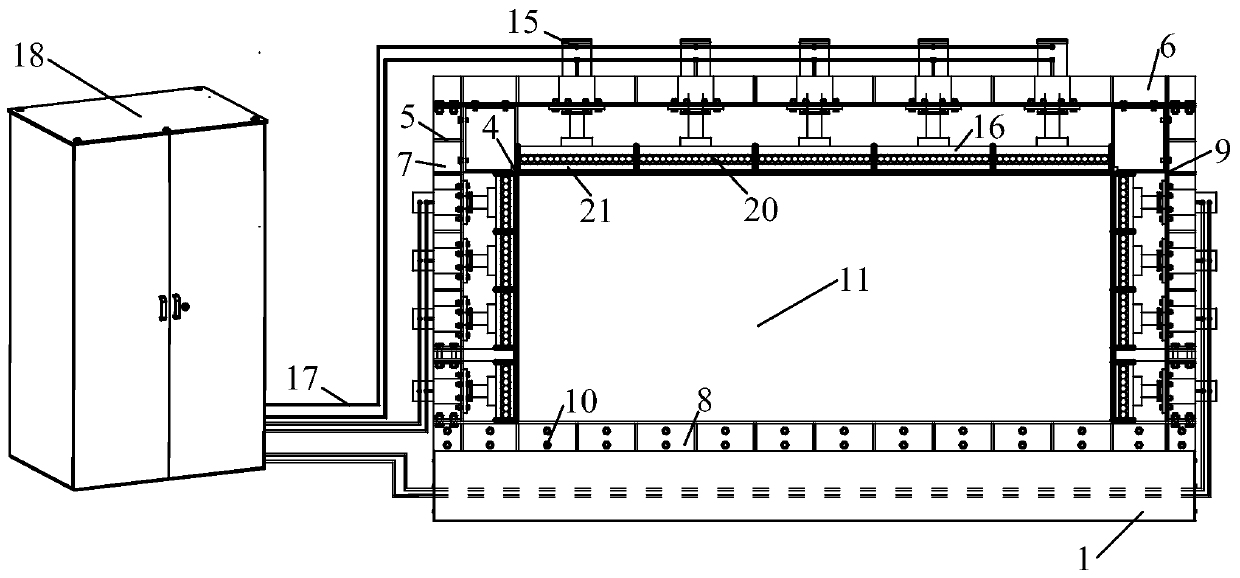

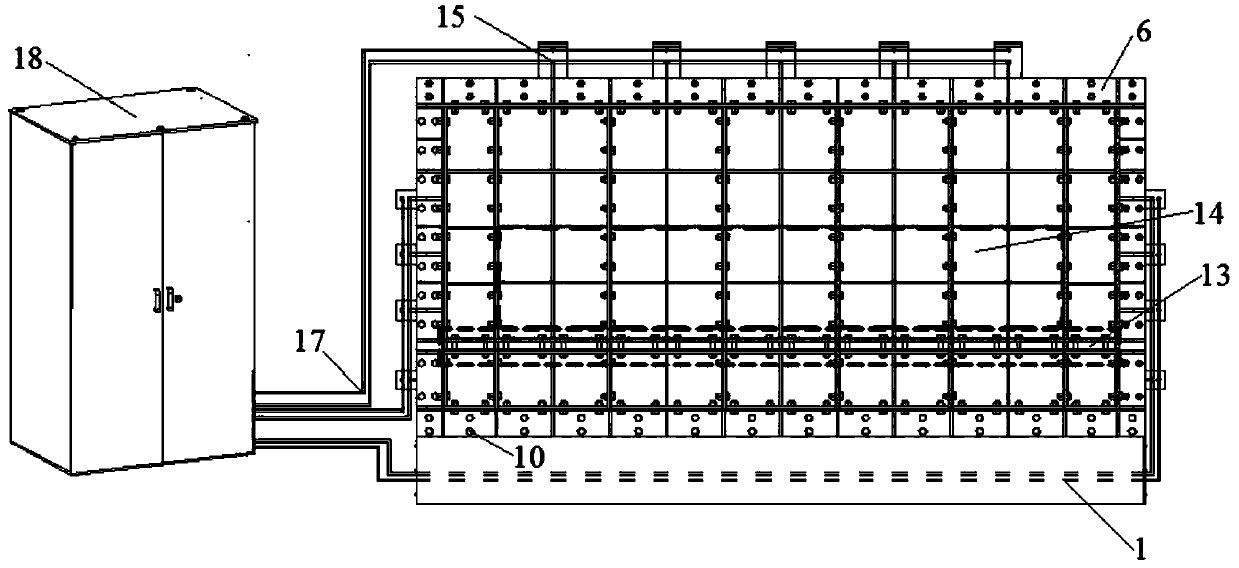

[0047] Attached below figure 1 - Fig. 5 illustrates the present invention in detail, specifically, the structure is as follows:

[0048] This embodiment provides an automatic mining model test device for self-forming roadway without coal pillars, including a combined reaction force device, a flexible loading device, an automatic mining roadway forming device and a monitoring device. The combined reaction force device is arranged above the base 1 as a model The test accommodates the reaction device of the model body; the flexible loading device is used for independent, automatic gradient loading and voltage stabilization of the test model; the automatic mining roadway device can simulate the mining of roadways, incisions and working faces; the monitoring device is set in the combination The image and data in the whole process of the test can be collected and stored.

[0049] The combined reaction device setting includes a modular reaction wall 2 and a frame 3, such as figure ...

Embodiment 2

[0065] This embodiment provides an automatic mining model test device for self-forming roadway without coal pillars, including a combined reaction force device, a flexible loading device, an automatic mining roadway forming device and a monitoring device. The automatic mining roadway forming device includes a mining simulation device and a cutting simulation Device, as shown in Figure 4 (c), the slit simulation device includes a high-precision laser cutter 28, the laser cutter 28 is located in front of the combined modular reaction force device, facing the position where the model body needs to be slit, through The intelligent control center 19 sets the slit pre-cracking program, and transmits the instruction to the wireless signal receiver located inside the laser cutting instrument 28, so that the laser cutting instrument 28 cuts the model body according to the set program, and the model body of the cut part The similar material vaporizes instantly to form a kerf.

[0066] O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com