An LED packaging device with increased light output angle and display application

A technology of LED packaging and light output angle, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of affecting the mixed light effect, the distance between LED lamp beads and diffusion plates cannot be further reduced, and the limitation of thinness of display devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

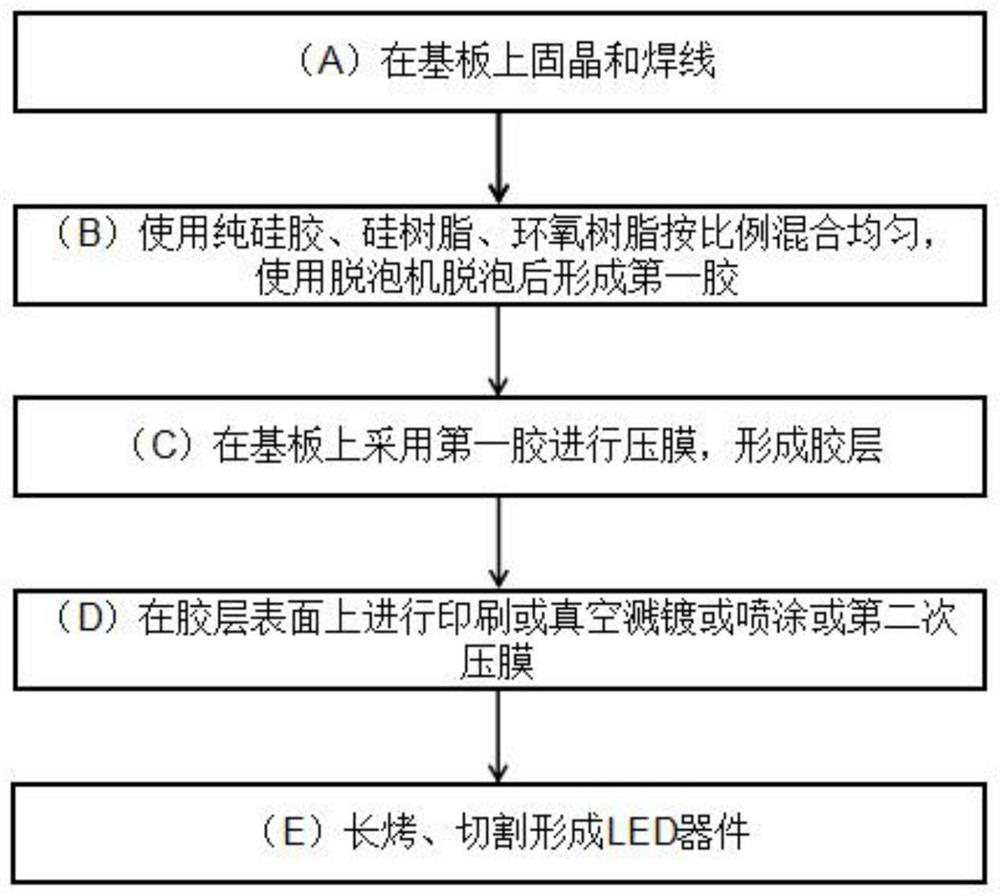

[0035] Such as figure 1 As shown, a kind of encapsulation process of the LED encapsulation device of the present invention that increases luminous angle comprises steps:

[0036] (A) Solid crystal and wire bonding on the substrate;

[0037] (B) Use pure silica gel, silicone resin, and epoxy resin to mix evenly in proportion, and use a defoamer to form the first glue after defoaming;

[0038] (C) using the first glue on the substrate to press the film to form a glue layer;

[0039] (D) Printing or vacuum sputtering or spraying or second lamination on the surface of the adhesive layer;

[0040] (E) Long baking and cutting to form LED devices.

[0041] Wherein, the defoaming parameters of the defoaming machine in the step (B) are 500 rpm for 30 s / vacuum 30 kPa, 800 rpm for 1 minute 50 s / vacuum 1.5 kPa, and 600 rpm for 50 s / vacuum 1.8 kPa to ensure uniform mixing.

[0042] In the step (C) after pressing the film, place it for 5-10 minutes to ensure that the surface of the adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| beam angle | aaaaa | aaaaa |

| beam angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com