A battery thermal management system and an electric vehicle

A battery thermal management and vehicle technology, applied in electric vehicles, battery/fuel cell control devices, vehicle components, etc., can solve the problems of large battery life power loss, low battery temperature, battery consumption, etc. Inexpensive and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

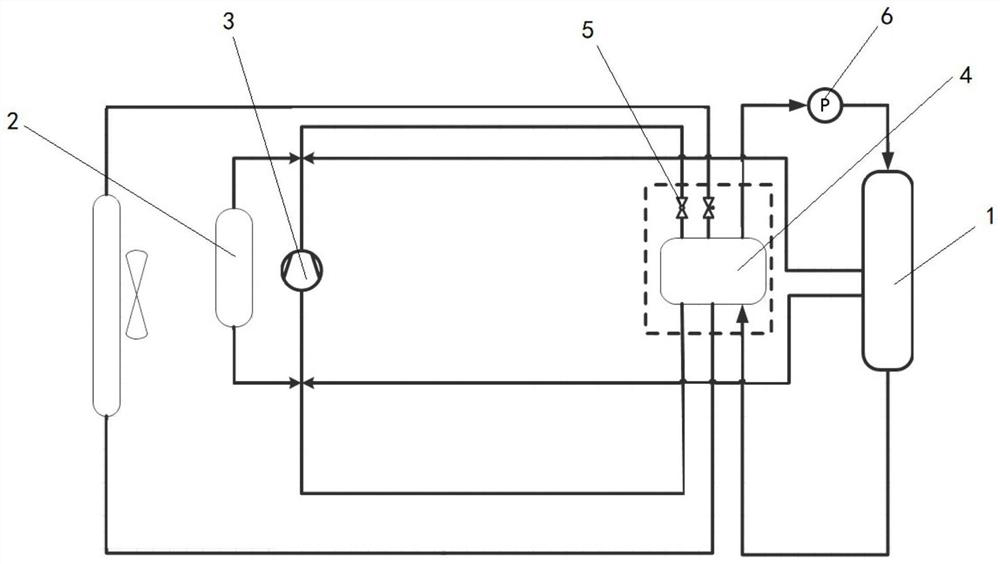

[0027] as attached figure 1 As shown, a battery thermal management system provided in Embodiment 1 of the present invention includes a lithium battery pack 1, a battery pack 2, a battery management module, a refrigerant subsystem, and a coolant subsystem. The lithium battery pack 1 is used for The battery pack 2 is connected in parallel with the lithium battery pack 1 to provide high-voltage current input for the vehicle in a normal temperature environment, and the battery management module is used for The temperature of group 1 selects the power supply battery group. When the temperature of the lithium battery group 1 is lower than the preset temperature threshold, the battery group 2 is controlled to supply power to the refrigerant subsystem and the coolant subsystem. The refrigerant subsystem It includes a compressor 3 and a heat exchange device 4, the compressor 3 and the heat exchange device 4 are connected through pipelines to form a loop, and the coolant of the coolant ...

Embodiment 2

[0037] Embodiment 2 of the present invention provides an electric vehicle, and the electric vehicle includes any one of the battery thermal management systems described above.

[0038] The electric vehicle can select the battery pack 2 to supply power to the vehicle when the ambient temperature is low, avoiding the use of the lithium battery pack 1 in a low temperature environment, and prolonging the service life and power of the lithium battery pack 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com