Tyre comprising reinforcing elements in the form of laminated strips

A technology of tires and strips, applied to the reinforcement layer of pneumatic tires, tire parts, vehicle parts, etc., can solve the problems of complex production and achieve the effect of easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] The following examples can illustrate the invention; however, the invention is not limited to these examples.

[0124] These examples are intended to demonstrate that the tires according to the invention have improved properties compared to control tires comprising conventional structures and tires according to the prior art.

[0125] The following tires, all in size 175 / 65R14, were compared:

[0126] - a tire PT1 comprising a conventional construction (the crown consists of two crown plies and a layer of nylon threads oriented at 0°),

[0127] - a tire PT2 according to the prior art WO2017 / 013575 (Fig. 8),

[0128] - Tires PA3 and PA4 according to the invention.

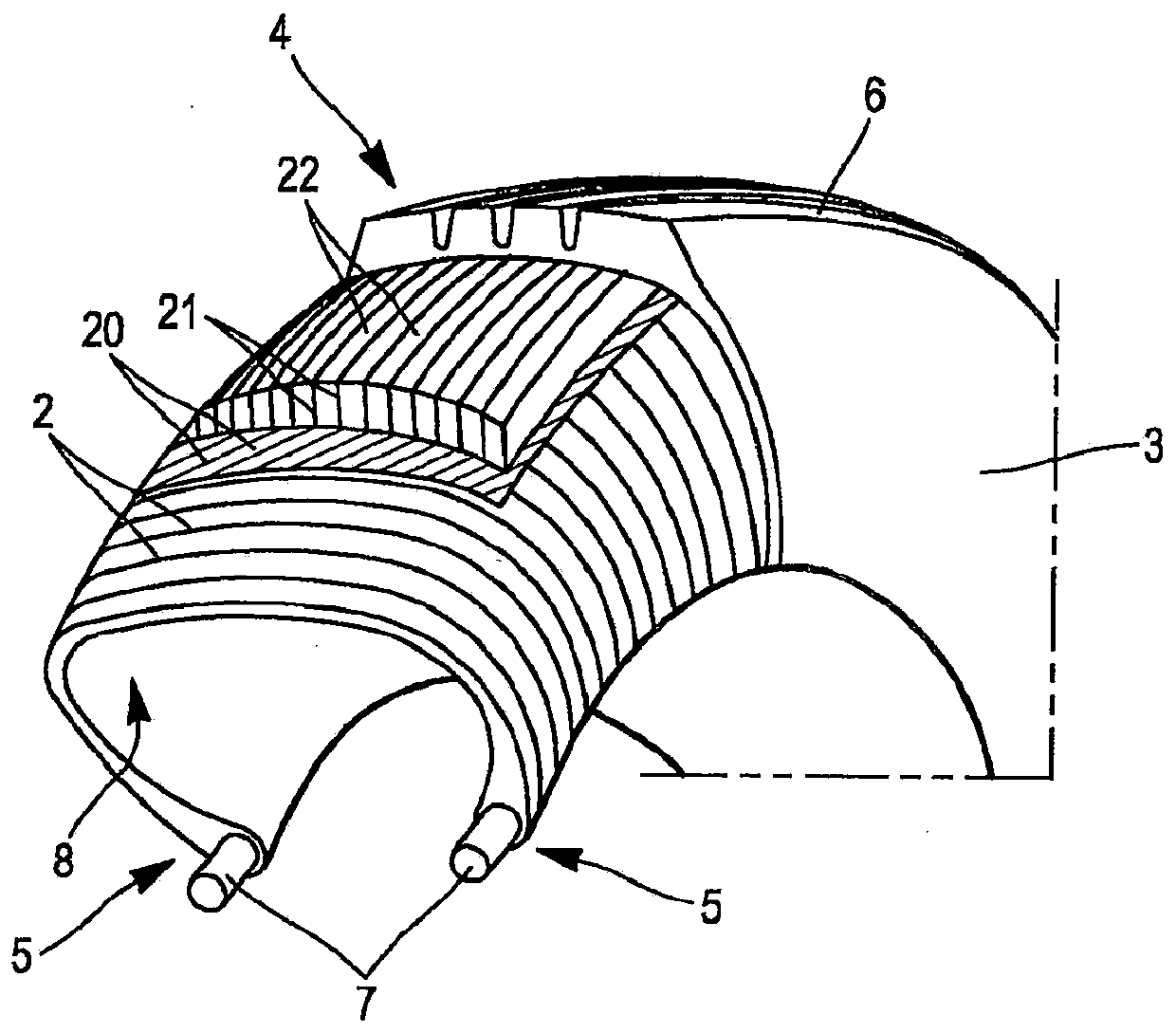

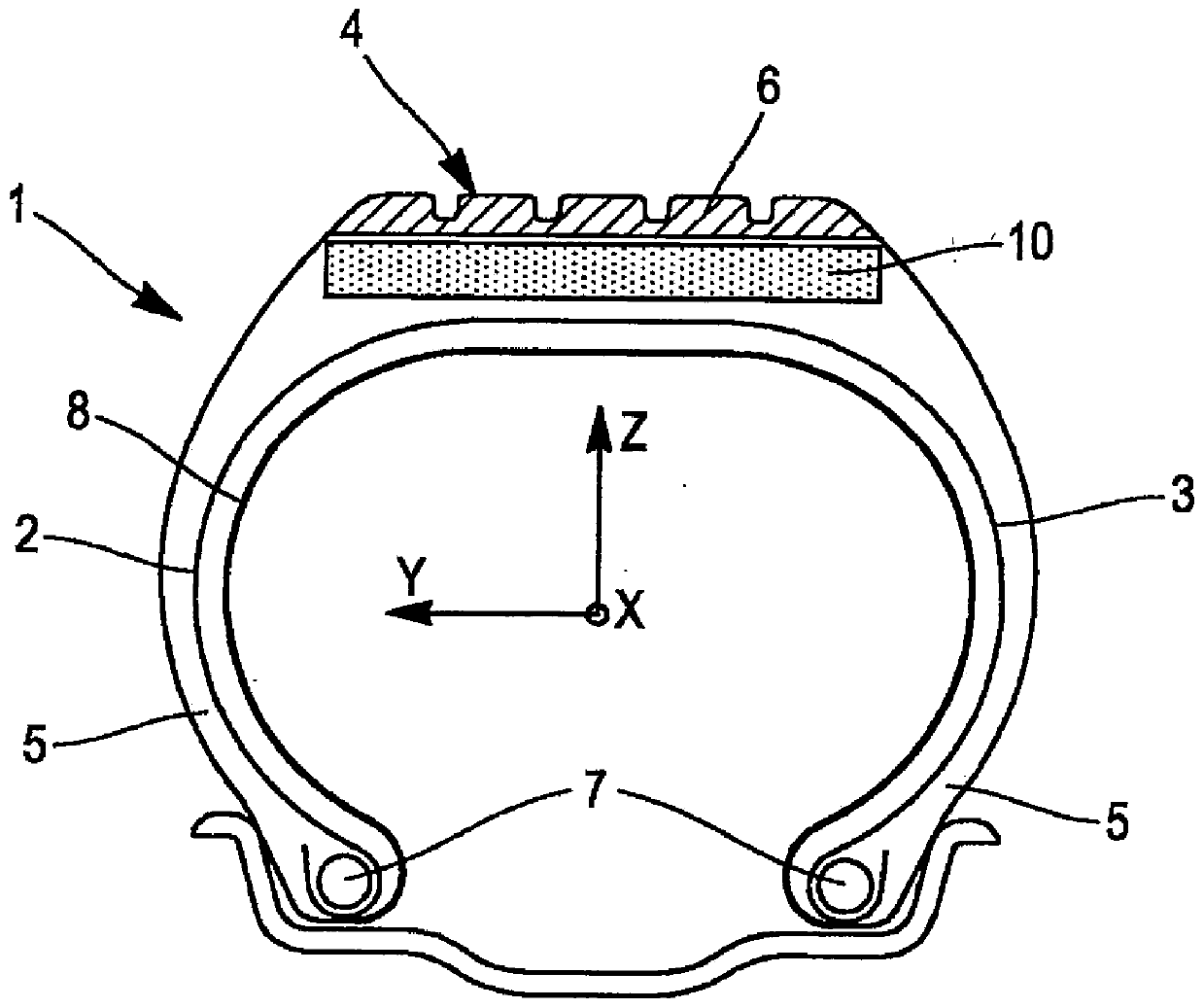

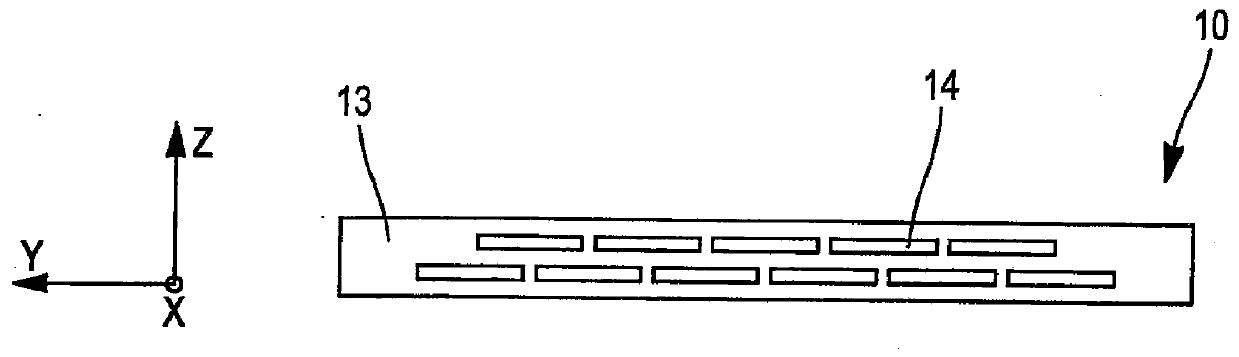

[0129] Compliant tires PT2, PA3 and PA4 each comprise a crown reinforcement zone comprising two strip plies made of reinforcing strips with a width of 15 mm, the reinforcing strips The belts are juxtaposed to each other and form an angle of about 0° with respect to the circumferential direction, the two be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com