Welding roller of mask machine

A welding and mask technology, applied in the field of mask machines, can solve the problems of low production efficiency of welding rollers of mask machines and unusable welding rollers, etc., and achieve the effects of convenient maintenance, low processing difficulty and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

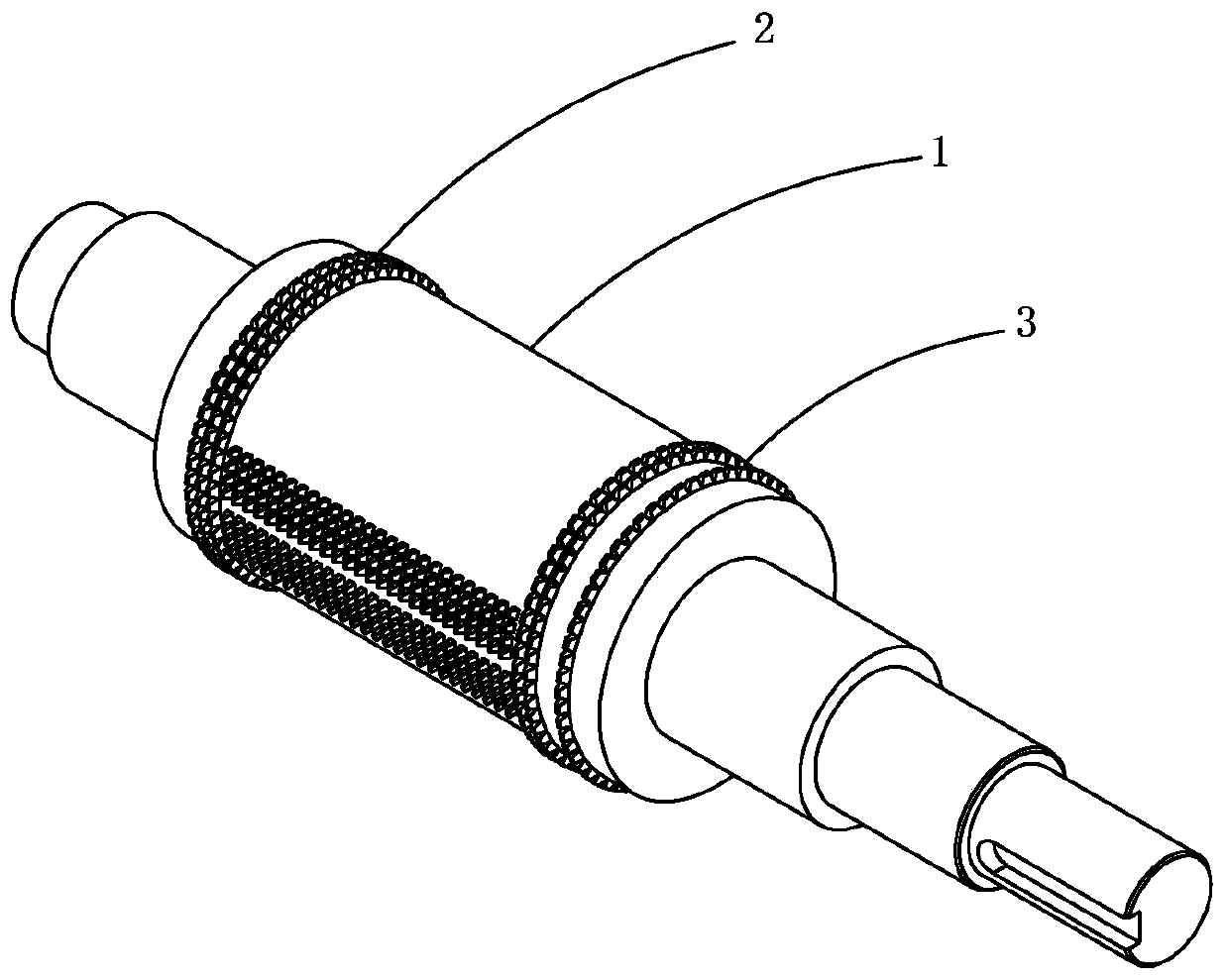

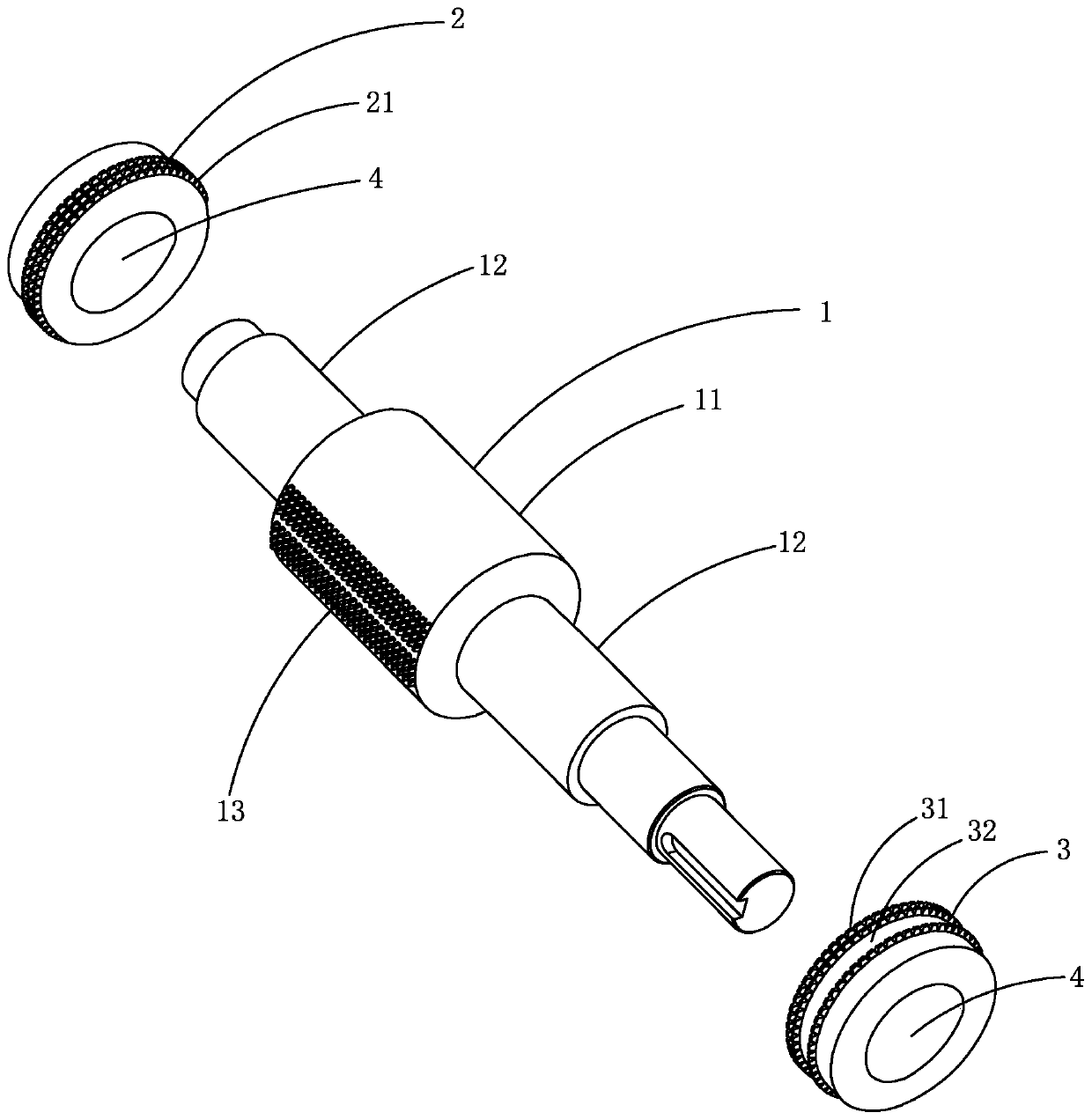

[0031] Embodiment 1: Please refer to the attached figure 1 , figure 2 , image 3 with Figure 7 , this embodiment provides a mask machine welding roller.

[0032] This embodiment includes a middle body 1 , a left end 2 and a right end 3 , the middle body 1 includes a roller middle 11 and connections located at both ends of the roller middle 11 and available for nested connection of the left end 2 and the right end 3 Part 12, the middle part 11 of the roller includes the edge sealing teeth 13 at both ends of the cheek that can press out the edge sealing and indentation of the two ends of the cheek in the mask, and the left end 2 includes the lower jaw that can press out the edge sealing and indentation of the lower jaw in the mask The edge sealing teeth 21, the right end 3 includes the nose wing edge sealing teeth 31 that can press out the edge sealing indentation of the nose wing in the mouth mask.

[0033] The mask machine welding roller provided in this embodiment divid...

Embodiment 2

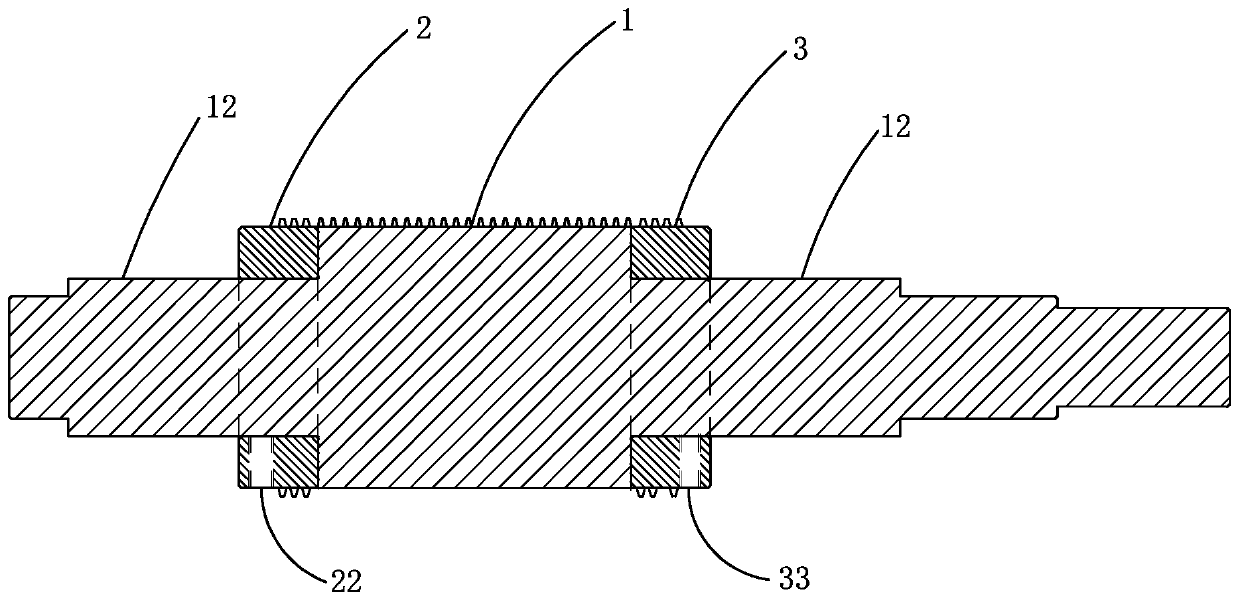

[0050] Embodiment 2: Please refer to the attached Figure 4 Compared with Embodiment 1, in this embodiment, when the left end portion 2 and the right end portion 3 are nested and fitted with the middle body 1, the left end portion 2 is provided for bolts to penetrate along the axial direction parallel to the middle body 1 and The left bolt hole 23 connecting the left end 2 and the middle part 11 of the roller is provided, and the right end 3 is provided with a right bolt hole 34 for bolts to penetrate in parallel to the axial direction of the middle body 1 and connect the right end 3 and the middle part 11 of the roller.

Embodiment 3

[0051] Embodiment three: please refer to the attached Figure 5 Compared with Embodiment 1, in this embodiment, when the left end 2 and the right end 3 are nested with the middle body 1, the two connecting parts 12 of the middle body 1 are respectively provided with a left end for locking. 2 and the fastening ring 5 of the right end 3. The fastening ring 5 and the connecting part 12 can be connected by threads, and the locking pressure is applied to the left end 2 and the right end 3 by twisting the fastening ring 5, so that the left end 2 and the middle body 1 and the right end 3 and the middle body 1 fit better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com